Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

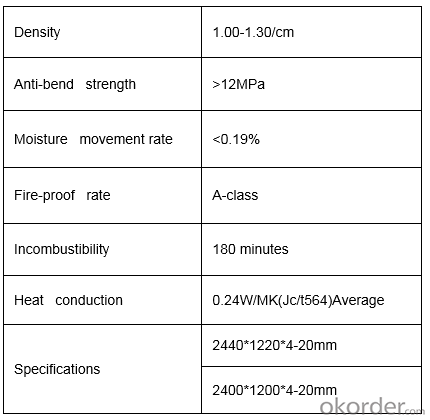

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with following factors: working temperature, bulk density, dimension (length*width*thickness), and quantity.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q: Calcium silicate board surface smooth it? Waterproof? Can I use this board to do the outdoor door?

- Yes, no problem, you can use this board to do outdoor door

- Q: The difference between calcium silicate board and plywood

- 9MM the following calcium silicate board is a fire board, 9mm or more called fire board. So now many of the domestic decoration with calcium silicate board, and the corresponding aluminum-plastic plate, gypsum board market has shrunk.

- Q: Calcium silicate board and noise board which sound insulation effect is good

- Calcium silicate board is a kind of sound insulation board, it is better than the same thickness of the gypsum board sound insulation effect is better, but not as thick as the thickness of the high pressure pressure cement board sound insulation effect is good.

- Q: Silicon calcium board and mineral wool board difference between the price is the price, and the advantages and disadvantages of the material

- Mineral wool board there is a better kind of engineering board and the like, the price is even higher. Specifically to see where you used, the office ah ah hospital this kind of mineral wool board with more, sound-absorbing good. Landlord can refer to the next

- Q: Calcium silicate board is not gypsum board?

- Gypsum board fire and waterproof performance is weak, it is being replaced by calcium silicate board. In price, the price of calcium silicate board is also slightly more expensive than gypsum board, but it is worth the money.

- Q: Indoor compartment with calcium silicate board or gypsum board is good?

- When decorating, the use of gypsum board more, calcium silicate board rarely used, generally only in the bathroom which will encounter. Gypsum board to do the wall, the construction is convenient, the price is relatively cheap.

- Q: What is the use of calcium silicate board with calcium silicate board ceiling is good

- Calcium silicate board is made of inorganic mineral fiber or cellulose fiber and other loose short fiber as a reinforcing material, with siliceous-calcium material as the main cementing material, pulping and molding, accelerating the curing reaction in high temperature and high pressure saturated steam to form Calcium silicate gel made of the plate. It is a kind of new building and industrial sheet with excellent performance. Its products are fireproof, moisture - proof, soundproof, insect - resistant and durable, and it is an ideal decorative plate for ceiling and partition.

- Q: Wood fiber board, calcium silicate board, mineral wool board difference

- In the beautiful appearance, calcium silicate board, mineral wool board is pure white, clean and tidy, wood fiber cement board surface with a unique texture, highlight the high value of texture.

- Q: How to identify whether calcium carbonate board contains asbestos?

- Asbestos calcium silicate board broken mouth will be very fine very fine wool (is plant fiber), after the fire is lit, is the smell of wood burning, no special smell; with asbestos calcium silicate board broken mouth will have Rough wool (asbestos), with the fire lit, there will be a very special smell, like the smell of plastic burning.

- Q: What is the difference between calcium silicate board and mineral wool board?

- Mineral wool board from the slag through high temperature, high pressure, high-speed rotation, remove impurities, washed into mineral wool, mineral wool board mainly by mineral wool, adhesives, pulp, perlite composition. The mineral wool board has similar characteristics of silicon calcium board, but the sound insulation performance is worse than that of gypsum board and silicon calcium board. It can not be waterproof. It is easy to deform.

Send your message to us

Low Price Calcium Silicate Board With High Quality

- Loading Port:

- Lianyungang

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords