Calcium Silicate Board for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

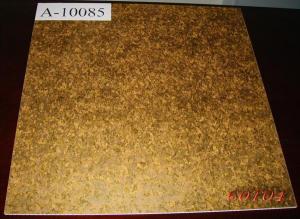

Specifications

1.100% non-asbestos

2.Bending strength 13MPa

3.Nonflammability A grade

4.Waterproof / fireproof

Calcium Silicate Factory

Fire Rated Calcium Silicate Board

Calcium silicate board is made from wood lengthy fiber, concrete

and silicon sand, under the high pressure water vapor process, therefore, it performs

well in humidity durability, force resistance and fire proofing. Yute fiber

cement board is suitable for indoor partition, ceiling and decoration.

CMAX fiber cement board presents the art of Germany know-how as a high quality

building material. It contains inorganic raw materials such as cement, silica powder

and reinforced cellulose fiber as the main materials. All CMAX boards are

autoclaved to become stable product. CMAX fiber cement board does not contain

any of asbestos fiber; however, it has strong bending strength like those with

asbestos.

CMAX fiber cement board can be applied not only for the interior use but also

for the outdoor wall system. It has low water absorption rate and high impact resistant

ability. These good advantages make it suitable for any purposes of applications.

Specifications:

1) 100% non-asbestos

2) Density: 1,000 - 1,400kg/cbm

3) Coefficient of thermal expansion: 0.24W/MK (JC/T54)

4) Bending strength: over 13MPa (GB/T7019-1997)

5) Linear expansion rate: 0.1%

6) Water absorption rate: less than 0.19% (GB/T7019-1997)

7) Water penetration rate: 0%

8) Water content: 10%

9) Incombustibility according to CNS 6532 and BS 476

10) Two point five three hours of fire rating for (6mm wall system with W-CSP concrete)

11) Radioactivity: standard (GB6566-2000)

12) Characteristic: nonflammability A grade (GB-8624-1997)

Features:

1) Heat insulation, stability, damp-proof, sound insulation, fire resistance and

light weight

2) The wall is solid and firm inside, and resistant to impact pressure

3) Painting, tiling and nailing is possible in the new system .

4) Noise reduction can be up to 46dB

5) Good efficiency

6) Working environment can keep it dry and clean for better management

7) Certificates with 2.53 hours of fire rating.

- Q:Calcium silicate board equipment

- Calcium silicate board equipment As the name suggests the production of fiber reinforced calcium silicate board equipment. But then buy a press to produce cement fiber pressure plate.

- Q:Calcium silicate board ceiling, wall patchwork and vertical degree how to control?

- If the height of the ceiling can be used to determine the height of the tile, you can use the wood is 3cm thickness * wall length, with steel nails to fix the wood on the wall above the tile, according to the determined installation height on the wood with ink bucket Horizontal Line Installation Edge. I hope I can help you

- Q:The real production of non-asbestos calcium silicate board manufacturers which is the company, and now all the calcium silicate board manufacturers are blowing their own asbestos-free, hoping to have a real asbestos

- Really free of asbestos sheet requires high strength fiber, the general manufacturers to add fiber for the recycled pulp (such as cement paper bags) and other plant fiber, but the strength is not enough, in order to increase the strength, will add asbestos to enhance, so that the production of low cost a lot of.

- Q:What is the difference between calcium silicate board and mineral wool board?

- In terms of health and environmental protection, mineral wool board mineral wool dust particles are easy to inhale the human body, and high carcinogenic substances; Calcium silicate board It is made of siliceous material (diatomaceous earth, bentonite, quartz powder, etc.), calcium material, reinforced fiber as the main raw material, cutting dust In terms of cost, mineral wool board the cheapest, calcium silicate board price center.

- Q:Gypsum board with calcium silicate board which is good? What are the advantages and disadvantages?

- Gypsum board advantages: light, low price, beautiful, easy to replace. Disadvantages: sound insulation performance is not easy to change the tide yellow, and the hardness is low. Silica calcium board advantages: light, moisture-proof performance, easy to change color, high hardness, good sound insulation performance. Disadvantages: replacement is not easy after installation, the installation of iron keel, the price is more expensive.

- Q:What is the size and classification of calcium silicate board? How do we choose the specifications for their own calcium silicate board?

- According to the formula points asbestos and non-asbestos, according to the thickness of 4 to 30 mm, and then in accordance with the use of partition walls and ceiling, according to the density of low density, medium density, high density

- Q:Living room light steel keel ceiling is gypsum board seal or calcium silicate board seal is better?

- Basically it is gypsum board. You said the closure of the floor should be used only gypsum board

- Q:Mineral wool board, silicon calcium board, aluminum slab plate is what is the difference between the use of the place, the more detailed the better.

- Mineral wool board and silicon calcium board are generally 600 * 600 specifications, used in offices and other small public places ceiling, aluminum slab board is more widely used, in addition to office and other public places, there are waiting room large space Use, and now also very popular in the home improvement in the kitchen bathroom with aluminum plate to do integrated ceiling.

- Q:What is the difference between gypsum board and silicon calcium board?

- Silicon calcium board, also known as gypsum composite board, the main raw material is natural gypsum powder (CaSO4), white cement (calcium silicate), glue, glass fiber. Strength is much higher than the gypsum board; completely changed the gypsum board due to moisture and deformation of the fatal weakness, several times to extend the service life of the material.

- Q:Is it harmful to calcium carbonate on home improvement?

- Asbestos content of 100% without asbestos, HBC223-2005 "lightweight wall panels" Radioactive Class A materials, production and marketing and use of unrestricted. In line with GB6566-2001 "building materials radionuclide limit" Non-combustible Class A incombustibility, in line with GB8624 "building materials combustion performance grading method" High-performance, high strength, fire, water, moisture, noise, insulation, insulation, shock, impact resistance, anti-aging, corrosion resistance, pest control, easy processing, easy decoration, stable performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board for Drywall Partition

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords