Calcium Silicate Board 650 degree Non-asbestos

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Board 650 degree Non-asbestos

Asbestos-free Boards Calcium Silicate also known as the porous calcium silicate board, is a fiber-reinforced calcium silicate board, with silicon oxide, calcium oxide, and the reinforcing fibers as the main raw materials, made through mixing, heating, gelling, molding, autoclaving and drying processes. Calcium silicate board is a new type of rigid insulation material.

The calcium silicate board products, also called asbestos free mipor calcium silicate products, are mainly used in industries like power, oil, chemical, shipping, metallurgy, light to provide thermal insulation on industrial pipelines and thermal equipment to decrease heat loss, lower cooling effect on medium and delay its condensation during production, meanwhile save energy, improve work efficiency, lower the temperature at work area, improve working condition, avoid scald among workers.

The calcium silicate board can be specifically used as thermal insulation layer of power plant boiler and turbine body, chemical plant cracking furnace and distillation column, steel plant heating furnace, drying oven, paper mill digesting kettle, also the thermal cover on the pipelines in these plants.

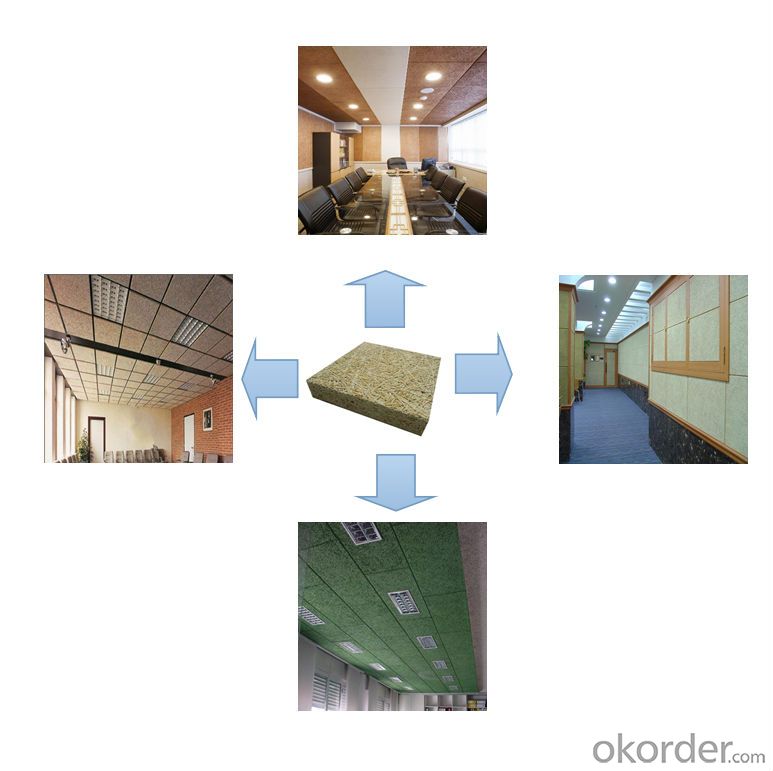

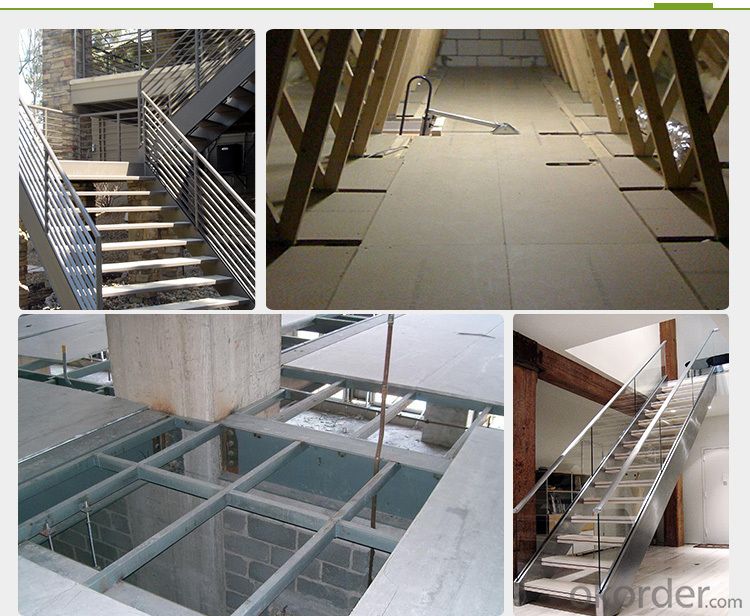

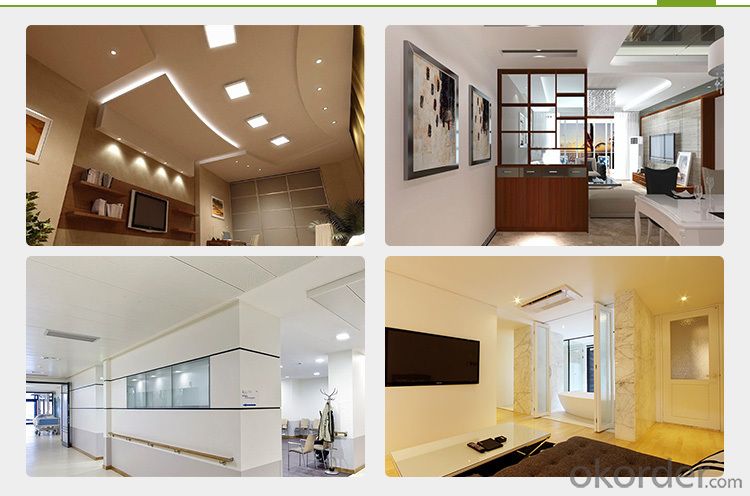

Product Applications:

Calcium Silicate Board are ideal for use in the below applications

Supermarket, marketplace

Underground, air port, bus station

Hall, corridor and toilet

Hotel, restaurant, kitchen

School, office, meeting room ,hospital etc

Product Advantages:

Good durability and can withstand high-temperature limit of the continuous thermal load

Low thermal conductivity,in the whole scope of use is unmatched within the adiabatic Performance

Light weight,high stength,its strength is rigid insulation products in the highest

Durability,long-term use of ceramic fiber felt no similar powder

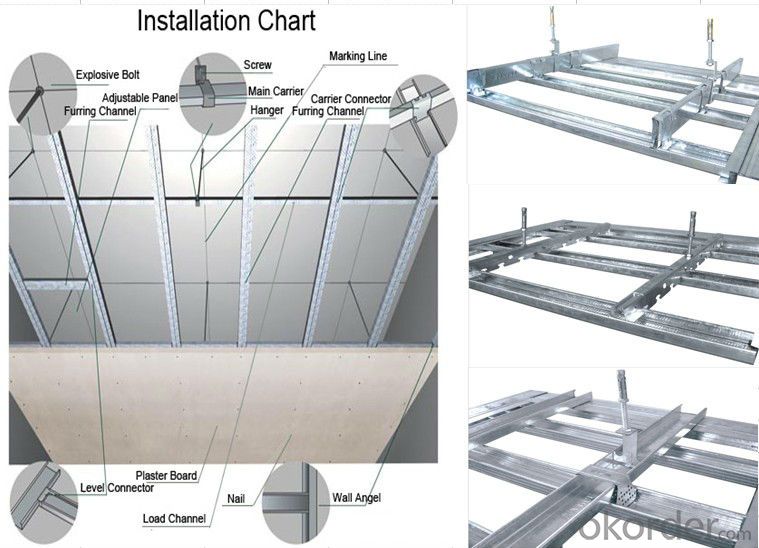

Construction practical,with ordinary tools can be arbitrarily cutting products

Used safety,hygiene,asbestos-free,sulfur,chlorine such poisonous substances

Main Product Features:

Great soft bulk with elastic.

High strength

The strongest refractory materials among the inorganic thermal materials with similar density

Heat resistance:

Non-deformation within the working temperature range

Thermal insulation:

Lower thermal conductivity compared with other massive hard refractory materials

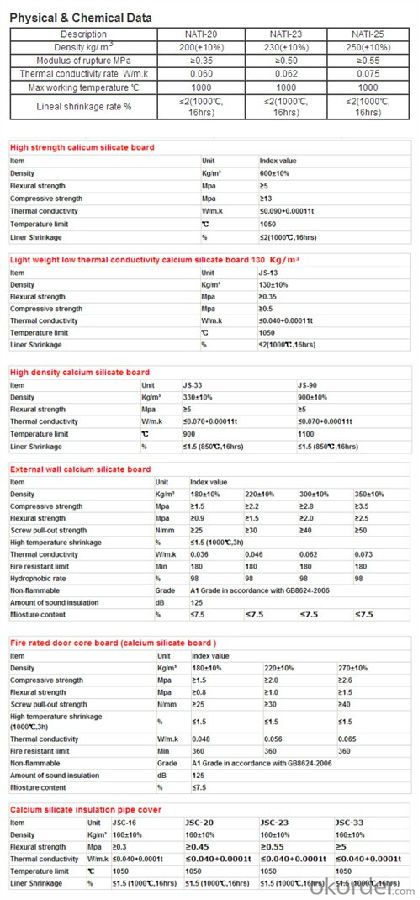

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

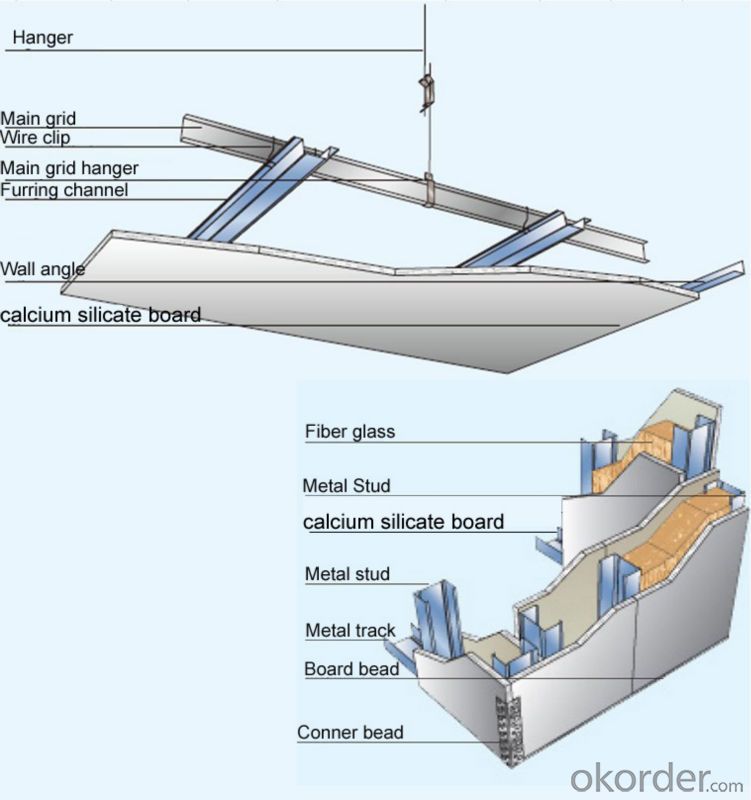

Produce Processing

- Q:What heat preservation material is used for thermal insulation of steam pipe in power plant? How thick is the bag? Please advise!

- Steam pipe in power plant thermal insulation rock wool board thickness, according to the temperature in the pipeline to choose, the higher the temperature insulation thickness is generally 80 to 150 mm.

- Q:What kind of insulation material can withstand 350-600 degrees of high temperature?

- Suggest that you refer to the above two data to choose from, select only from the temperature, you can use

- Q:Calcium silicate board white ICI belongs to wood surface paint?

- ICI can generally be considered as wall paint (latex paint), and latex paint can be used on this kind of cement board. And lumber is different, it is not suitable to brush latex paint on the surface of wood, it can only be decorated with paint (oil paint).

- Q:Calcium silicate board for house ceiling, 6mm or 8mm?

- Calcium silicate board with fire prevention, moistureproof, sound insulation, thermal insulation, indoor air in wet conditions can attract water molecules in air, air drying, and the release of water molecules, can adjust the indoor humidity, dry, increase comfort. Natural gypsum products and special fireproof material, the flame can produce endothermic reaction, at the same time, the release of water molecules to prevent the fire from spreading, and does not produce any toxic decomposition, corrosive and choking gas, will not produce any smoke or combustibles.

- Q:What's the difference between white carbon and carbon black? Can they be replaced?

- White carbon black in color rubber products instead of carbon black reinforcing, meet the needs of the white or translucent product. Anti aging performance of silica with strong adhesion force, tearing resistance and heat, so the black rubber products can replace part of the carbon black, in order to obtain high quality rubber products, such as off-road tires, engineering tire, radial tire.

- Q:What's the use of white portland cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q:What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q:What are the main use of lime?

- Lime stabilized soil mixes lime powder or lime powder with various crushed or formerly loose soil, and is obtained by mixing, compacting and curing. It is called lime stabilized soil. It includes lime soil, lime stabilized gravel soil, lime crushed stone soil and so on. Lime stabilized soil has a certain strength and water resistance. Widely used as a building foundation, ground cushion and road base.

- Q:What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q:Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Aitken is a brand of non asbestos calcium silicate board is a product name

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcium Silicate Board 650 degree Non-asbestos

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords