Fiber Cement Board with Both Sides Sanding Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

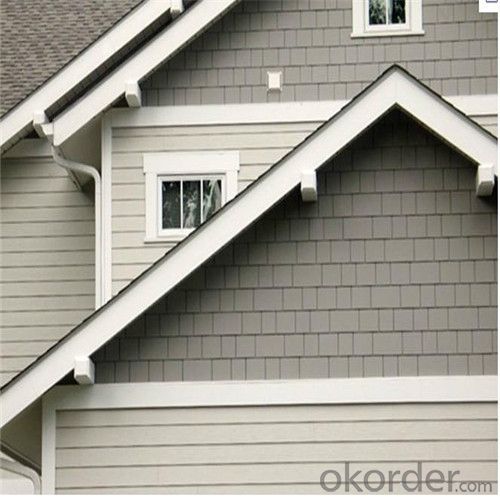

Products Introduction:

Our fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and high temperature advanced technologies, Sanle fiber cement board is a new building material with excellent performances.

Features

Fire Proof & Insulation

Class A non-inflammability, no toxic gas, low in perveance, good electric insulation material

Waterproof and Moisture Proof

In semi-outdoor area and under high temperature condition, performance of Sanle boards is stable and will not bend or deform.

Thermal Insulation and Sound Insulation

Low thermal conductivity, good heat insulation, high in density, sound proof

Light weight & High strength

Pressured by 5000-ton hydraulic machine, it is high in strength and light in weight. It is not easy to deform and bend, and good for flooring and roofing.

Easy installation

The installation of boards is dry operation, which is faster. It can be processed with ordinary wood working tool. The board is easy to be processed.

Economical and Good looking

The boards are light in weight. Together with the use of keels, they can save cost of construction and decoration. The painting is uniform, and the surface is smooth, making the exterior of buildings good-looking and attractive.

Safe and Harmless

Test result of Sanle boards is better than national radiation protection standards of building materials. The radiation from Sanle boards is equal to that from the lawn 20 meters away from the building. The lifespan of Sanle boards is very long, and they are resistant to acid and alkali, moisture and insects. The toughness and strength remains the same when time passes by. So they can be used for a long time.

Description:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German,

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Can cement board be directly approved for cement?

- The cement board is made of stones, sand, cement and steel.

- Q: i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- I am assuming you are going with ceramic tile. If that is the case then you do not need fiberboard. Just tile right to the concrete floor. As for the crack either fill it in or use a product called RedGaurd. RedGaurd is a rubberized product that when applied over the crack will expand and contract and thus keep the crack covered. You can apply RedGaurd then put mortar right over it.

- Q: Does backerboard need to be installed for new kitchen tile with cement floor?

- Backerboard is used to stiffen the wood subfloor when you lay tile. This is important so the subfloor doesn't deflect when additional weight is put onto it (thus, breaking the tiles). Since you have a cement floor, putting down a backerboard wouldn't make any sense, but the floor does need to be level. You can pick up self-leveling compound at the hardware store. It's going to be in the same aisle as grouts, tools, etc.

- Q: could someone please recommend (a) thin set, manufacturer, brand, this is a bathroom application. perhaps a Lowe's or home depot product.

- Custom Building products, sold at Home Depot is what I ve used for years.. You can use the white or grey, just that the grey is just a bit cheaper too. For porcelains you ll want the Flexbond line in the Custom thin set. It s the one recommended for porcelains. Also in the past I ve used H B Fuller s Tec lines of thin sets. love that line, it mixes to a nice creamy consistancy. But its not as available to the public and more expensive. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Plaster in the (3) layers they used to install on homes years ago is just as heavy as cement board-if not heavier. No worry about wood being able to support the cement board. As far as your house of concrete - you need to do some serious pricing of materials and labor for all aspects of your dream home. First of all you need to price lots or land, then cost of site work such as driveway, Tap fees for water,sewer, or you may need septic system if rural area. If you choose a building method that is off the wall - you should be prepared to pay $200-$300 or more per square foot.

- Q: We are building a new house and I am going to install tile in the bathrooms myself, we have the drywall hung and will be sanded in the next day or two. My question is, can I go ahead and hang the Cement backer board in the showers? or do I need to wait until the drywall is sanded or primed? Thanks :o)

- hang away my friend

- Q: I am seeking to set porcelain tile on top of the hardibacker board once it is secured. If I have to remove the Barmaill plywood, does anyone have any suggestions on how to do this with ease? I assume its glued as well as screwed down.

- Make sure the plywood is waterproofed by applying a couple of coats of matte polyurethane to it....let it dry completely. Thin set contains water, and you do not want the plywood delaminating. Once the surface is preped, and the plywood is very solid...no flex allowed!, apply thin set and set backer board into it. I usually use drywall screws and screw it down all over the place to make sure the board is in perfect contact with the thinset and backer board. USE Latex fortified thin set or Epoxy thin set...will adhere very well to the sealed ply. NOw, you are ready to set tile...Have a ball. Good luck.

- Q: Sorry for the double post, this is an addendum to my previous question. I am planning to re-tile the downstairs foyer. Since it's on the 1st floor of a townhouse with no basement I think there's cement slab underneath, but if I need backer board I need to purchase and make arrangements to cut (I don't own a saw yet). I'd like to take a couple tiles off to check, but how can I tell the difference between the two?

- You won't be able to pound a nail into the concrete.

- Q: i am using cement board to cover a wood floor before laying tile. the last time i used it, i cut it with a circular saw (what a mess) dust everywhere. is there a better way??

- Sorry - a jig saw would also make a mess. THere might be some sort of scoring device. I say predetermine your cuts and cut outside with a carbide circ saw. WEAR A RESPIRATOR and eye protection.

Send your message to us

Fiber Cement Board with Both Sides Sanding Standard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords