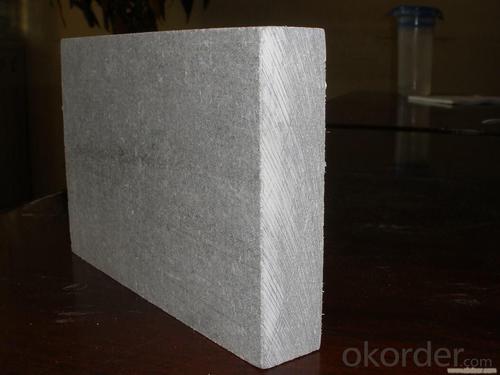

Fire Resistant Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

on-asbestos Fiber Reinforced Calcium Silicate Board

Refractory temperature:1770-2000°C

Grade: A1 incombustible

Thermal conductivity: 0.03

Material: cellulose fiber

Shape: rectangle

Form: flat sheet

Size: 2440*1220*(4-40)

Product Advantages:

Product categories: fire prevention board

Flexure strength: 14

Operating temperature: normal temperature

Introduction

Non-asbestos fiber reinforced calcium silicate board is low shrinkage fiber cement preesure board which uses cement, quartz, lime, fly ash, cellulose fiber, inorganic fiber and other materials as main material, manufactured by advanced technology and techniques to form green sheet, and then pressed by thousands tons pressure, cured by high temperature and high pressure steam and other special treatment.

Product feature

Fire prevention, waterproof, high strength, corrosion resistance, heat insulation, sound insulation, durable, long service life, safe and convenient construction.

Main applications

Non-asbestos fiber reinforced calcium silicate boards are mainly used in all kinds of internal and external wall: insulation wall, sound absorption wall, casting wall, compound wall, overclapping wall, scales wall, subway(underground) water gushing wall, thermal insulation wall, exterior thermal insulation panels.

For ceiling: sound absorbing roof, sound insulation roof, large flat, T-top roof and so on.

For decorative panels: (surface coating, paste decoration) furniture barrier panels, acoustic enclosures, electrical insulation board, industrial board, ventilation pipe plate, free open type templates.

Main Product Features:

thermal conductivity:0.048w/m.k

model size 600*300*50mm

working temp 1000C

linear shrinkage 2%(1000C 6H)

100% asbestos free

Advantages of Calcium Silicate Board:

Characterized by exceptional heat resistance,outstanding thermal insulation,very low bulk density,high specific strength,excellent durability and flexible construction,high temperature calcium silicate insulating slabs can be widely used as energy-saving materials for almost all types of industrial furnaces.

Properties of Insulation Calcium Silicate Board:

Product Specifications:

| Items | Unit | HCS-17 |

| Bulk Density | kg/m3 | 220(±10%) |

| Flexural Strength | Mpa | ≥0.30 |

| Temp.Limit | °c | 1000 |

| Linear Shrinkage | % | ≤1.5(1000°c 3hrs) |

| Thermal Cond. | W/m.k | ≤0.048+0.00011t |

Images:

- Q: I need to cut a curved piece of cement board. Will it work to score it with a utility knife, then break it? Thanks.

- Yes it cuts just like drywall, scrore then snap.Score a bit deeper though.

- Q: Where is the cement pressure plate installed?

- Light keel plus cement pressure plate: Formal method: only use three light keel plus two pieces of cement pressure plate production. Light Gang keel did not make the frame, but played a connection role. This is not strong enough. But the provincial workers expected material. Formal methods: the use of light keel made of frames, after the supervision and acceptance by the Party, and then sealed cement pressure plate, linked to steel wire mesh, and finally paste the disk. Features: not easy to deformation, nowadays the most commonly used company decoration process. Plastic buckle plate, plastic aluminum plate production: These two methods for home decoration finished, and want to wrap up the riser. Because it is not necessary to fill the disk, it is convenient. Plastic buckle: wood keel plus angle, directly from the bottom of the buckle up into the installation. Disadvantages: not beautiful. Aluminum-plastic plate: wood keel on the nail nine PCT board, and then all the glue to the aluminum-plastic plate stick to a variety of colors, close to the disk effect. Disadvantages: aluminum-plastic plate angle is easy to crack, should use thicker plate.

- Q: Is it ok to pour floor leveling compound over hardibacker cement board?

- ive used a liquid leveling compound on it and got great results on cement board though the drying was spotty and needed more than one layer to achieve desired results. it was only on a very small area about 8 x 10

- Q: Our contractor says green board is required for his corian shower because it is coved and waterproof. Is he right? The City says cement board is a new requirement because mold can get in. However, they will accept the manufacturers recommendation. We want to follow the building code.

- Fibre cement board should be used in showers, bathrooms, and other 'wet areas'

- Q: Factory roof directly painted on the cement board directly spray the white again

- Do not require a full cover, and so spray the paint does not stick and then spray. Several spray can be completely covered.

- Q: What is the use of fiber cement board

- Fiber cement version can replace paper gypsum board, and in terms of strength, fire and moisture are much better. Fiberglass trim panels replace stone and decorative tiles for wall finishes. Because of its specifications generally 1220 * 2440, can be the whole board on the wall, so do the wall decoration with stone and tiles can not do the big face of the solid color effect. Fiber cement panels are widely used in Europe, especially in Japan.

- Q: Looking to connect a piece of plywood between two boards to hang a banner

- I am okay with the 5 gallons of concrete, that will weigh close to 100 lbs per bucket. I would use 1.5 - 2 inch pvc pipe, not 2x4's. That will give you better flex. For the banner, it is up so high that the wind loading and leverage will be a problem if you tie all four corners. So just connect the two poles with a rope at the top and hang the sign from the rope. This way in a wind, the bottom will just blow free. If you must tie the banner at 4 corners, you need a flatter container of concrete. An old tire, filled with concrete, will work for this purpose. Put a piece of plywood across the tire so it will hold the concrete. That's what we used for tether ball.

- Q: I am planning on doing cement around bath and shower in my home. i already have cement backer board up and wire mesh screening. what do i use to make it not crack and smooth and what material do i use

- You're welcome to do whatever you want, but concrete is porous like grout. Ever seen nasty grout? Even sealed grout gets disgusting without proper maintenance (ie squeegee) and cleaning. Imagine that all over the wall. Even if you make it ultra smooth and seal it my guess is that this would get disgusting in a hurry...unless you happen to have a power washer in your bathroom... ;)

- Q: This is a 1950s sink.

- I assume that you mean the tiles are attached to the counter-top. The process is called demolition, and it can get dusty. Safety glasses are a must, a dust mask is recommended. First, starting at the back-splash, slice any caulk at the seams where the tile joins the wall with a sharp knife. Then, crack the tiles, enough to get a pry-bar under them. Peel, pry or knock the tiles off, exposing the plywood or cement board underneath. If you can find screws or nails attaching the back-splash to the wall, remove them. Then, look underneath the counter for screw or nails which attach the cabinet to the wall, remove them. At this point, you can try prying the whole structure away from the wall(s). Be careful about pry-bar placement. You should only pry where there is a stud on the inside of the wall, typically every 16. If it doesn't budge, look for any fasteners you missed. NB- Before you start, turn off the water, disconnect all the plumbing, cover the drain pipe (to keep debris out of it and sewer gas inside it. A drop-cloth would help in the cleanup. expect to spend some time patching the wall when you're done. Good Luck

- Q: What is the exterior wall of a light steel structure house?

- Exterior wall paint in accordance with the decorative texture is divided into four categories: 1, thin-walled exterior paint: delicate texture, materials than the province, can also be used for interior decoration, including flat paint, sand-like, mica-like paint. 2, layer pattern paint: pattern was concave and convex, full of three-dimensional sense. 3, color sand paint: with stained quartz sand, porcelain mica powder as the main raw material, color novel, crystal brilliant. 4, thick paint: can be sprayed, can be coated, can roll, can be made of hair, but also to make a different texture pattern.

Send your message to us

Fire Resistant Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords