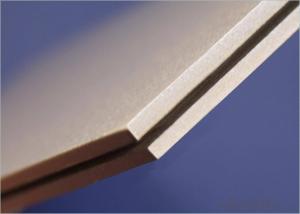

Fiber Cement Board 1220*2440mm Fiber Cement Board 1220*2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: As an artist, I'm experimenting with plaster and cement.As a resident of a temperate zone, I'm wondering about temperature, curing times, and bonding to substrate.I'm working on square pieces of particle board. I rough up the surface with a wire brush to improve bonding to the substrate.Both plaster and cement create heat as they solidify. Are either impaired by a low (and possibly sub-freezing) temperature? I have a makeshift oven that can reach 110 to 120 degrees (F) regardless of the outside temperature. Will heating cement or plaster to this extent improve its ability to bond to wood? Might it only reduce setting time?

- The British give this name to modern day cement. Ordinary Portland cement,sulphate resistant cement, white cement and Grey cement and so on. Most have chemical name but Portland is a patent name.

- Q: Fiber reinforced silicate board which is good

- Pummelian fiber reinforced silicate fire board by the selected quartz powder, mica, perlite and high quality plant fiber and a variety of mineral fibers and then supplemented by cement and add special fire materials, high temperature, high pressure steaming, High stability known to Tobima to stone crystal structure-based high-tech green energy-saving light construction fire board.

- Q: Plywood, gypsum board, cement board, aluminum-plastic board, which to choose, why?

- Plywood is the use of different materials fixed to decorate the use of materials.

- Q: should I use cement board or a leveling compound for my tile flooring?

- Cement board is the best. It will help the floor stay true and will help the grout from cracking. Tiles will not come lose from the hardi-backer or wonder board as easy as leveling compound. And it helps to keep moisture down also.

- Q: Its a baffle over an old fireplace where a gas heater has been installed. A cement based repair was hopeless, builders glue lasted a while but eventually busted when heater used on high for lengthy period. Crack getting bigger so need to get it fixed before a re-installation becomes necessary. Thanks.

- go to mitre 10 or place makers and ask an assistant to show you a heat resistant cement that will glue cement board but in saying that gorilla glue is fairlie versatile however companies have spent years discovering the best adhesive for every purpose and I'm conident you will find just the right stuff

- Q: How the cement pressure plate sticks on the brick

- Crack: tiles shop after 24 hours to clean up the hook, hook before the first floor of the gap should be wiped with impurities, with a special sealant joints. Clean up: in the home decoration tiles construction process with the dry with the clear, after the completion of (generally should be after 24h) and then cotton yarn and other objects on the surface of the brick. The quality of floor tiles: floor tile clean, clear pattern, consistent color, uniform seams, the surrounding straight, hook seam smooth, plate without cracks, angle and lack of shock phenomenon.

- Q: This board is sometimes refered to as tile board.

- Rip out everything to the studs. Put up tile BACKER board. (Durock)

- Q: Can I just paint a stone on a cemented fiberboard?

- Can be painted, and my 6 big house is used to make this kind of plate for the compartment, for the rental.

- Q: FC fiber cement plate can be affixed to the aluminum plate?

- FC fiber cement pressure plate can be affixed with aluminum-plastic plate, but use glass adhesive paste.

Send your message to us

Fiber Cement Board 1220*2440mm Fiber Cement Board 1220*2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords