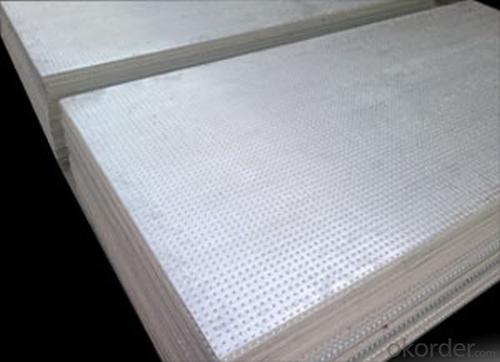

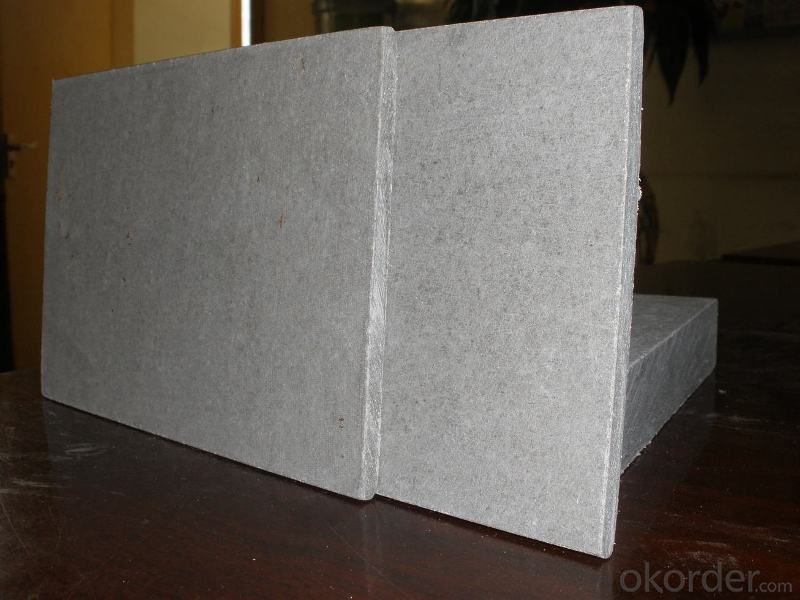

Exterior Wall Decorative Fiber Cement Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

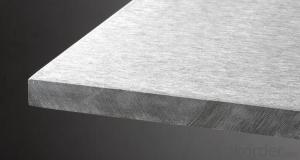

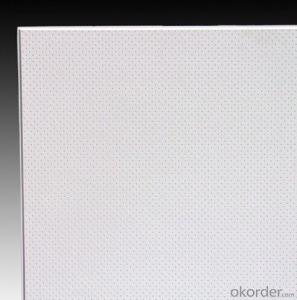

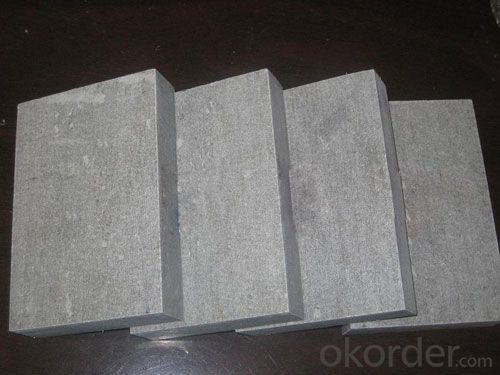

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: I have asbestos shingles and i need to vent a portable a/c so i'm going to replace a few shingles with fiber cement board so i can cut them. i heard these things are a nightmare to cut.

- if you only need it for one hole get a cheap one, cement board is hard on any hole saw so i have saved my good ones and bought throw aways. if you want a good one buy Milwaukee, there still made in USA

- Q: do you have to tape cement board before tiling?

- you dont have to but the idea is to fill and fiberglass tape the seams keeping them ridged so that in years to come the grout doesnt crack out. Yet thats something rather new, you should be fine just filling any of the voids with mastic adhesive as you lay them. A portland cement mix works well on durarock, and the new backer board, though drywall quickset works just as well.

- Q: My bathroom has a section where there is cement board. Over the cement board is a layer of plaster. Tiles were glued to the plaster. However, the plaster came off of most of the cement board over time. Of course, the tiles have fallen off too. So now I have bare cement board partially covered by plaster.I'd like to remove the remaining plaster from the cement board and then retile directly over the cement board.How to best remove the remaining plaster? Is chipping away at it the only method?

- By the use of paraffine

- Q: I found these in a house I bought and am not sure what they are nor what they would be used for. I'd hate to just throw them out if they could be used.

- I guess I would use them in a basement insatallation. Or in a bathroom.. It's drywall. Slap it up amd call it a day.

- Q: why is gypsum always interground with cement clinker during the final stages of portland cement manufacture?

- Because they are trying to dispose of Gypsum and this is one of the few ways that it can be blended with something else in large quantities. Gypsum is produced as a by-product form the de-sulphurisation of flue gasses from power plants that still burn dirty fuels like coal or oil residues. There is often thousands of tons of this stuff produced every day and it has to be dumped somewhere. Land fill sites are filling up rapidly and charge big fees for disposal so it is very attractivce to belnd it into cement products. Gypsum is also used as the main part of plaster board which is another place to get rid of the unwanted material.

- Q: How does that work what do they have that makes them moisture resistance?

- Hydrophobic property make it moisture free.

- Q: What kind of mortar do you use to tape joints in cement backer board?

- thin set. the same mortar you use to set the tiles with.

- Q: I want to cut off a lip of about 1/8 by 1/2 to accomodate the upper lip of a tub. I plan to do this with several passes of an abrasive wheel in a circular saw set to 1/8. My question is will I be able to machine the board like this or will I get a crumbling mess? the Hardiback is 1/2.

- Hardibaker peels like an onion in layers. We use it half thick often and we just cut it to size and then using a razor knife pushed in between the layers and pull them apart like opening a peanut butter sandwich. This may help you. If you run that saw on the line where you need the lip to start on the board then use your knife to split the layers and peel them down to the cut you made. This may be an easier solution then eating away the excess material a little at a time. Good Luck.

- Q: i am using cement board to cover a wood floor before laying tile. the last time i used it, i cut it with a circular saw (what a mess) dust everywhere. is there a better way??

- Sorry - a jig saw would also make a mess. THere might be some sort of scoring device. I say predetermine your cuts and cut outside with a carbide circ saw. WEAR A RESPIRATOR and eye protection.

- Q: i'm going to be putting in durock in my shower? what kind of screws do i use? do they have cement board screws?

- Anodized drywall screws

Send your message to us

Exterior Wall Decorative Fiber Cement Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords