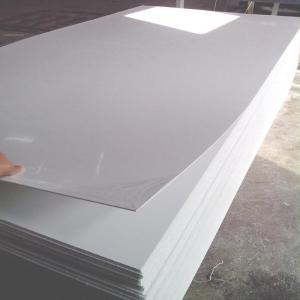

UV coating board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LUTAI coating board is a slap-up interior&exterior decorative material with high -tech green enviromental protection.Based on the multiple inorganic material by high pressure. The surface adopt spefical technics to coating UV curable fluorocarbon dope. And will have a refreshing experience due to rich color,lively line .better effect of simulation.Enviromentalprotection,unvioresistant,alkali&acid-resistance ,corrosion-resistance,firproof,duration weather ablity,dampproof, durability,stable color, bacteriostat,weather resistance .

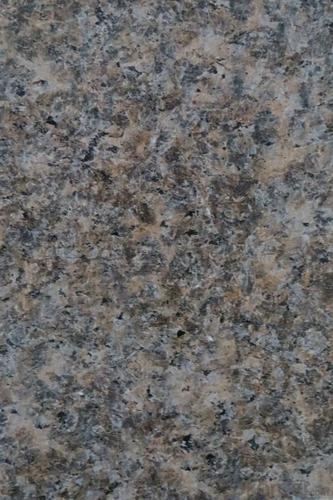

There are four types of this product .They are PURE COLOR SERIES , STONE TEXTURE SERIES ,RHINESTONE SERIES ,WOOD GRAIN SERIES .

TEST ITEMS | RESULT | ||

PHYSICAL MECHANICS PROPERTY | DENSITY | ≥ 1.4G/CM3 | |

WATER CONTENT | ≤ 10% | ||

WATER ABSORPTION | ≤ 28% | ||

WATER IMPERMEABILITY | The duration of the test shall be 24h, traces of moisture may appear on the under surface of the sheet , but in no instance shall there be any formation of drops of water | ||

IMPACT RESISTANCE | The surface of sheet doesn’t have penetrating crack when using once falling ball impact test | ||

BENDING STRENGTH | >16MPA | ||

FREEZING RESISTANCE | Without no crack and delamination after 25 times freeze thaw recycling test . | ||

INCOMBUSTIBLE | GB8624 A GRADE | ||

RADIOACTIVITY | Internal exposure index | ≤ 1.0IRa | |

External exposure index | ≤ 1.0Iγ | ||

COATING QUALITY | GLOSS DEVIATION (60) | ≤ 10 | |

ADHESIVE FORCE ,LEVEL | ≤ 1 | ||

PENCIL HARDNESS | ≥2H | ||

MORTAR RESISTANCE,24H | No changing | ||

WATER RESISTANCE,168H | No abnormalities | ||

ACID-BASE RESISTANCE,168H | No abnormalities | ||

DAMP AND HOT RESISTANCE,1000H | No bubbles , no rust, no crack | ||

COLD RESISTANCE OF THE HEAT CYCLE (TEN TIMES ) | No abnormalities | ||

POLLUTION RESISTANCE | PASS | ||

DIRT-PICK UP RESISTANCE | ≤ 10% | ||

RINSING RESISTANCE (TIMES) | ≥10000 | ||

SOLVENT(BUTANONE) WIPING TEST (TIMES) | ≥100 | ||

SOLT FOG RESISTANCE ,4000H | No bubbles , no rust, no crack | ||

ARTIFICIAL WEATHERING AGING RESISTANCE ,4000H | No bubbles , no falling off, no crack | ||

- Q: Oulang cement fiberboard and Taiwan Rong calcium carbonate plate difference

- Cement board is cement as the main condensing material through the formation of natural conservation, high strength, but the deformation coefficient.

- Q: I had to make some necessary repairs behind the wonderboard and I ended up making 6x6 inches holes through the cement board. I have repair sheetrock in the past but this cement board looks difficult to repair. I have googled online on how to do the repairs but I could not find much. Thank you in advance for all who will answer.

- Patching Cement Board

- Q: Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Home decoration to do the attic, channel structure, decoration master said just just to shop a layer of 1.8cm wooden multilayer board and then shop the floor, multi-layer board formaldehyde exceeded, want to replace the wood multilayer 5mm aluminum.

- Q: I'm trying to install tiles on the back of my stove's wall, so grease won't stick on the wall and it can be easier to clean the tiles versus the wall. I've read the DIY instructions in the internet, but since I'm not installing tiles in a wet area, is it necessary to get green drywall or cement back board? Thanks. Any help is appreciated.

- Mine are fine and they are on the regular drywall. For the protruding tile problem: many kitchen tile styles have border tiles with a finished edge, look for them when you choose the tile.

- Q: Application of cement pressure plate

- Cement pressure plate can be used for LOFT steel structure sandwich, movable room wall floor and so on.

- Q: Tile seems to be an expensive options. Want a finished look for less than tile

- There are concrete stains that you might look into. I've seen them in several colors. Check at your nearest hardware store and see what they know. There might still be a little color difference, but at least it may even the colors out more.

- Q: the post box had 2 -2x6 boards somehow attached to the cement. The boards rotted out and fell over in a windstorm. I'd like to attach a 4x4 post bracket on the cement, then put a pressure treated 4x4 post for the mailbox. I think I need to get the bracket fixed so it's level before I drill into the cement. would I use an epoxy glue to do this?

- If you can bore a one-inch or larger hole down through the concrete stump, you might be able to sink a metal holder made for deck posts and pour a little binder cement around that. I mean, how strong do you need to hold some mail?

- Q: I'm pulling up the linoleum and replacing it with ceramic tile, 12x12. it's a small bathroom, on the 2nd floor.Under the linoleum is wood. Do i need to lie down cement board before I put the mortar mix down? Or will it be fine to put tiles on the mortar mix on the wood?

- You should have a backer of some type. There are a number of options available now so the choice is yours and dependant on the circumstances of your project regarding which one would be best. While many people do install tile directly over a wood sub floor that does not make it right. Tile has considerable permanence. It is somewhat involved to properly install and difficult to remove if the installation is not done correctly. The final outcome of a tile installation, like so many other projects depends largely on the preparation. So many people skip many of the necessary early steps that really do not cost that much extra but make a huge difference on the outcome. Use a backer system. G. Borders Home Repair, Improvement, & Handyman Service Plano Home Repair

- Q: Dry hanging cement fiberboard is not curtain wall

- Fibreboard with uniform material, vertical and horizontal strength difference is small, easy to crack, etc., widely used. Manufacture of 1 cubic meter of fiberboard about 2.5 to 3 cubic meters of wood, can replace 3 cubic meters of lumber or 5 cubic meters of logs. Development of fiberboard production is an effective way of comprehensive utilization of timber resources.

Send your message to us

UV coating board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords