Molecular Sieve 4A with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. For drying and purifying

2. Excellent manufacturer and exporter

3. FREE SAMPLES at any time

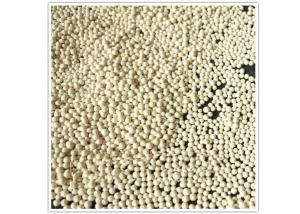

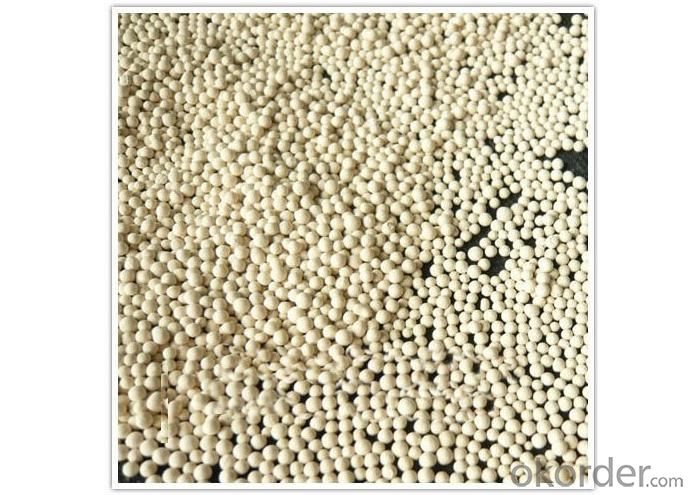

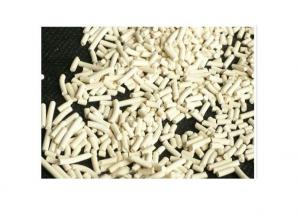

Molecular Sieve 4A

Molecular sieve 4A is an alkali alumino silicate;it is the sodium form of the Type A crystal strcture.4A molecular sieve has an effective pore opening of about 4 angstroms(0.4nm).Our 4A molecular sieve will adsorb most molecules with a kinetic diameter of less than 4 angstroms and exclude those larger.Such adsorbable molecules include simple gas molecules such as oxygen,nitrogen,carbon dioxyde and straight chain hydrocarbons.Branched chain hydrocarbons and aromatics are excluded.

Molecular Formula

Na2O Al2O3 2.0 SiO2 4.5 H2O

Specification And Application

Specification | |||||

Item |

Unit |

Technical data | |||

Shape |

|

Pellet |

Sphere | ||

Diameter |

mm |

1.5-1.7 |

3.0-3.3 |

1.7-2.5 |

3.0-5.0 |

Size Ratio Up To Grade |

% |

≥98 |

≥98 |

≥96 |

≥96 |

Bulk Density |

g/ml |

≥0.66 |

≥0.66 |

≥0.66 |

≥0.66 |

Wear Ratio |

% |

≤0.20 |

≤0.40 |

≤0.20 |

≤0.20 |

Crushing Strength |

N |

≥30/cm |

≥45/cm |

≥30/p |

≥70/p |

Static Water Adsorption |

% |

≥20.5 |

≥20.5 |

≥21 |

≥21 |

Ethylene Adsorption |

% |

≤3.0 |

≤3.0 |

≤3.0 |

≤3.0 |

Water Content, As Shipped |

% |

≤1.5 |

≤1.5 |

≤1.5 |

≤1.5 |

Application | |||||

Drying and removing of CO2 from natural gas, LPG, air,inert and athmospheric gases, etc. | |||||

Removal of hydrocarbons, ammonia and methanol from gas streams (ammonia syn gas treating). | |||||

Special types are used in the air break units of buses, trucks and locomotives. | |||||

Packed in small bags, it may be used simply as a packaging desiccant. | |||||

Attention | |||||

To avoid damp and pre-adsorption of organic before running, or must to be reactivated. | |||||

- Q: How long till rubber cement sets?

- Rubber cement is actually rubber in a solvent. As the solvent evaporates out, the rubber thickens more and more until it is hard. So, it varies, according to how much of the rubber cement is exposed to air so the solvent can evaporate. It works so well on paper and other things like paper because paper is porous. The paper is like nothing is there to prevent the solvent from evaporating. It will take forever to cement hard plastic since plastic is not porous and the solvent can only get out at the small edges that are uncovered. Nail polish is the same kind of dissolved solid, that hardens as the solvent evaporates out. In nail polish, the solvent is acetone, which is what is mainly in nail polish remover. Rubber cement also has a thinner available for when your can of rubber cement gets too thick.

- Q: The house was built in 1925 without foundation tile, over the years whatever was painted over the brick interior walls has bubbled because of the moisture that would have been diverted by an appropriate ditch around the foundation, or tiles to drain it, etc. Several of these bubbles are basketball in size, and there are cracks in many areas of the stucco-like stuff that chips off in large pieces. I want to patch it up, and repaint, what is that stuff called? It looks like cement when chipped off, is it joint compound? How should I go about this? Moisture problems have been aleviated, now I just need to fix the cosmetics.

- It's a special type of waterproofing finish that is meant for block walls--probably a type of stucco with added plastic compounds that make it impervious to water. You can't use joint compound---it's not meant to be applied over block, stone, or brick. You have to use a grout-like substance--something that contains an adhesive to make it stick, and some additional ingredients to keep it from absorbing water. Go to your local box store, hardware or construction store and ask them what they would recommend--take a piece of the chipped off stuff with you so they can identify what is already on the walls. Then use a waterproof basement paint to finish it off after you patch. I gotta tell you, though--if you have a problem UNDER the stuff now, (because it's bubbling and cracking) you won't get rid of that problem by patching--you may have to get a pro in there to waterproof and seal the block from scratch. And that's a lot of $$.

- Q: My friend wants to know.

- First you got to find and catch the rat bastard who's going to wear them. Then you make a box out of plywood about 1.5 ft tall and big enough that he can stand in. Stand him in it and fill the box with cement. Quickcrete brand cement is usually your best option. Let it dry, then have your snitch try them out at the bottom of a river or lake. You should be able to find all the tools and supplies you need at your local hardware store.

- Q: Is it better to sink fence posts in cement or geavel?I keep getting mixed answers on this. To me filling the hole with gravel will not be as sturdy as cementing the posts in. Which is better in the long run????

- Funny you should ask. I'm replacing a fence in the next couple of weeks. This isn't the first fence I've built. My method is to dig the holes (approx 2 ft deep for a fence that'll be 6 feet high), pour a little bagged cement mix in the hole, and put the post in there. Using a level, make sure the post is plumb (straight up and down) both ways and use some scrap lumber or a couple of fence pickets to hold it there. Now pour the rest of the concrete mix into the hole. Use enough to come right up to the top. Now water the mix and use a piece of rebar or something to churn the mix so that water gets all the way to the bottom. It looks good if you finish off the top of the concrete with a trowel or even a piece of wood to smooth it out. Let the concrete dry overnight and you're good to go. The concrete mix under and around the posts all the way up to grade will protect the post. I'd still use treated lumber made for ground contact, though.

- Q: I want to do a flooring of my new house by Cement:Sand (1:3)ratio and would like to know the quantity of cement needed per square meter for plastering. The floor thickness will be 2~3mm.

- You need to calculate the volume of your floor Assume a 1 square meter area and assume the thickness is .3 mm (not .2) The volume would then be = 0.0003 m x 1 m x 1m = 0.0003 cubic meters Volumetricly, you need 1/4 part concrete + 3/4 parts sand to equal 0.0003 cubic meters. The concrete volume would then be 0.000075 cubic meters concrete per 1 square meter of floor (at .3 mm thickness).... or 75 cubic centimeters per sq meter The density of Portland cement is about 3 g per cubic centimeter therefore 3 g/cm3 * 75 cm3 = 225 grams or 0.225 kg of cement per square meter of floor

- Q: The Now building materials business to do it, including what aspects?

- Because the environment is not very good, the traditional building materials more difficult, recommend some new environmentally friendly building materials, such as Karon ecological wood is similar to the better! Of course, no matter what stage people have done a good taste of the end of the period, Do everything to have vision, perseverance!

- Q: how many bags of portland cement do I need to build a slap of 40m by 30 m by 10cm?

- Contact Portland Cement, their reps will be able do the calculations for you. They will need to know which Portland cement product you are using.

- Q: Part of my cement retaining wall has small cracks and I think after I patch into them I can paint with thinned out cement to blend it in. Would this work?

- Yeah that's a nice way to patch the cracks and it will work definitely.

- Q: When installing cement backer board, is it necessary to put down some thin set mortar and then lay the board and screw in place, or can I do without the thin set?

- You do not need thin set. Just screw it in place.

- Q: We need to concrete our forge floor, we need to mix it ourselves as we are in the middle of nowhere so ready mix can't be delivered. Can anyone tell us how many bags of cement and how much of aggregate for a cubic meter?

- for a 4000 lb. mix you will need 6 bags of cement (564 lbs.) 1,452 lbs. of sand and 1656 lb. of gravel...this is from the batch plant for 1 cu. yd. ...when i mix by hand , i mix by volume...1 bag of cement is 1 cu. ft...so for every 1 bag of cement i would add 3 cu. ft. of gravel and 2 cu. ft. of concrete sand...by the way i have yet to see a place the trucks cant deliver it...

1. Manufacturer Overview

| Location | Rizhao, Shandong, China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America; South America; Southeast Asia; Africa; Mid East |

| Company Certifications | Certificate of Quality; certificate for products exemption from quality surveillance inspecction; ISO9001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Rizhao port |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese, French, Russian |

| b) Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Molecular Sieve 4A with Good Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 5000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords