Single component Polyurethane waterproofing coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

01 Product introduction Product Introduction

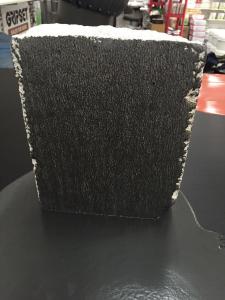

Single-component polyurethane waterproof coating, the main components of isocyanate, polyether polyol, and a variety of functional additives prepared by the reactive elastomer waterproof coating. Its waterproof film forming mechanism is to cure cross-linking with water vapor in the air after contact, forming a three-dimensional network structure, forming a layer of flexible and strong overall waterproof film on the surface of the substrate, so as to achieve a better waterproof effect.

02 Product characteristics

1. High construction efficiency, convenient and fast: single component, ready to use;

2. Good mechanical properties: reactive waterproof material has large tensile strength, high elongation, strong adaptability to base cracking and expansion;

3. Low temperature flexibility is very good :-35℃ bending without cracks, ordinary waterproof materials can not do, suitable for low temperature waterproof projects;

4. Strong bond with the base: no need to brush the base treatment agent, the bond strength can reach 1.0MPa;

5. Excellent water resistance: wet curing reactive polyurethane coating, the coating is dense, no pinholes, no bubbles, water permeability coefficient is small, can be waterproof and can be used as a gas insulation layer;

6. Green environmental protection: the use of low volatile solvent, non-dangerous goods. Does not contain benzene, toluene, xylene and other harmful solvents.

03 Applicable scope

1. Basements and roofs of industrial and civil buildings, large venues;

2. Subways, tunnels, Bridges;

3. Kitchen bath room, swimming pool, water channel;

4. Parts with complex shapes that are not easy to coil construction, such as vertical and horizontal parts of pipelines.

04 Packaging and storage andtransportation

1. Pay attention to safety during storage and transportation, avoid sun and rain, prevent extrusion collision, stay away from fire source and heat source, pay attention to ventilation and drying.

2. Storage temperature should be 5-40℃.

3. Under normal storage and transportation conditions, the storage period is 6 months.

【 Product Specification 】20Kg/ barrel

- Q: A complete set of basement waterproof construction program

- Second, the basement of the external walls of water leakage construction preparation 2.1 Technical preparation 2.1.1 Selection of construction methods Waterproof engineering is related to the use of the project an important indicator, it is the construction process of a key project, difficult engineering. The choice of construction methods and programs has a direct impact on the quality of construction. The underground wall of the project SBS waterproofing membrane with hot melt method full construction. 2.1.2 before the start of the project, the first organization of engineering and technical personnel to enter the construction site, to understand the situation, to further understand the characteristics of the project to solve the contradiction between the construction technology and the implementation process. 2.1.3 technology before the end of the construction of waterproofing works by the professional foreman in accordance with the construction drawings and the existing national norms require the actual situation of the project to the construction team in writing to the end. The contents include construction site, construction sequence, construction technology, construction level, node fortification method, enhancement site and practice, project quality standard, guarantee the quality of technical measures. And after the field technical person in charge of the strict implementation of the audit.

- Q: What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: What is PE waterproof cloth and PVC tarpaulin

- Waterproof cloth product features and the use of attention 1. Has a waterproof, mildew function, and a light material, high tensile strength, Naisuan Jian, high temperature, easy to wash and so fold the characteristics of folding; 2. This product should be used in the process should avoid sharp impact with the sharp metal; 3. If the product is damaged, can be used to repair glue.

- Q: Home improvement waterproofing problem

- 4, through the door stone paving need to do waterproof, you can directly use cf-2000 efficient composite waterproofing agent treatment, can play paste, waterproof two effects. Just on both sides of the door to do the character to strengthen the treatment on the line can be foolproof.

- Q: What is the price of a waterproof window cover?

- 3, decorative panels Decorative panels are divided into paint-free panels and paint panels. Currently on the market, there are many window-free products, paint-free board is 5 mm density, the board pressure a layer of thin layer of color paper, due to the type of color paper, so there can be a lot of paint-free Color. Paint decorative panel is the surface of a layer of veneer plywood, there are many types, different wood has different colors. The benefits of window sets

- Q: There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q: Roof leakage, what materials do the best waterproof

- Treatment is: large cracks available plugging the king, a small crack can be used to fill the glass glue, repair with a wall waterproofing agent, after spraying a few words on it. As the external walls of cracks and cracks need high-altitude operations, the public must ask the professional construction team to deal with, to prevent accidents. Roof leakage what materials: available SBS modified asphalt - polyester film coil, polyester film SBS-3mm, laying the coil. Roof waterproofing membrane, in addition to SBS modified asphalt, there are three EPDM coil, neoprene. Can also use architectural ointment, cement, polyurethane coating. You can also use asbestos net also do waterproof. If the cement roof cracks, I suggest you use cf-2000 efficient composite waterproofing agent. In the concrete like scraping putty scraping 5mm thick again, you can play a waterproof repair function. Can also slot repair.

- Q: Developers have done waterproof, decoration house also have to do it

- so, in your house When the decoration, or should do a waterproof treatment.

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar and cement mortar difference: Cement mortar is the synthesis of three main materials, cement, sand and water, and mixed mortar is the synthesis of four major materials, cement, sand, lime and water.

Send your message to us

Single component Polyurethane waterproofing coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches