Good Quality Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Breathable Membrane

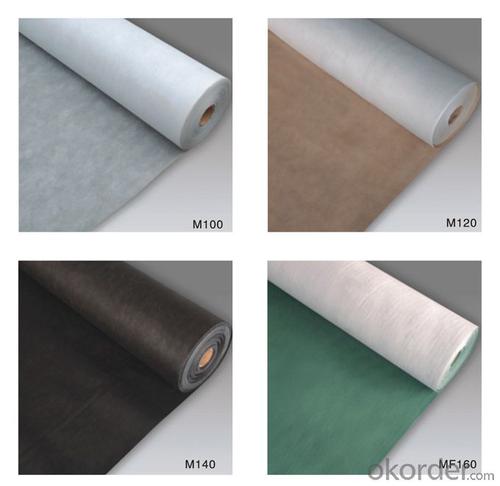

| Description of 3 layer breathable membrane: |

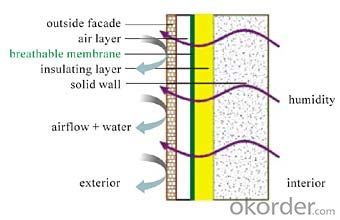

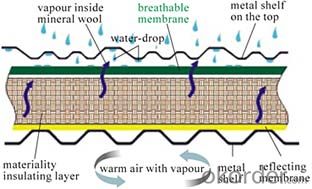

| Breathable membrane is thermal laminated by the high polymer material in the middle layer . Paving on the top of the insulation system, it can strengthen the water tightness of the building, as well as to eliminate humidity inside the containment by the unique breath ability, thus to retain the duration of building effectively , playing a part in thermal insulation, energy conservation and living environmental improvement.

|

| Building up principle of 3 layer breathable roof membrane: |

| 3 layer breathable roof membrane, thermal laminated by high polymer material + polyolef in microporous membrane + high polymer material, we create this technology in China which is advanced all over the world. Polyolefin microporous membrane has excellent breathability, as well as good duration. Polyolefin microporous membrane has not only acid and alkali resistance, but also good extensibility which enable the fasresilience after tearing by nail so that to improve the sealing performance.

|

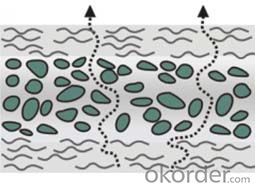

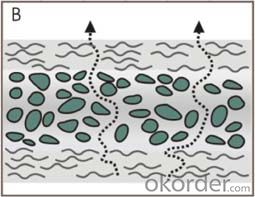

| Operating principle: |

| There are two kinds of operation principle for breath: microspore and hydrophilic group. Breawarf breathable roof membrane adopt the principle of microspore. The minimum diameter of water drop is about 20 micron while the diameter of water vapour molecule is about 0.0004 micron, because of the enormous difference, water vapour can get across according to the dif fusibility, while water molecule can't pass because of the surface tension. As a result, the breathable membrane can prevent osmotic water , so that to have the water proof function.

|

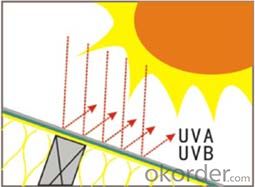

| Characteristics of 3 layer breathable membrane: |

| A Excellent Performance at water resistance B Particular function of vapour permeability, so called breathable membrane C Good performance at UV resistance

D Tear resistance, wear resistance, good extensibility. |

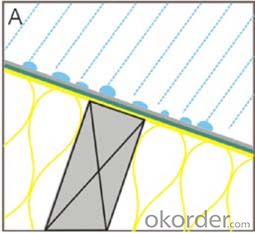

| Function of 3 layer breathable membrane: |

| Air-tightness of Breawarf breathable membrane Breawarf breathable membrane paves outside of the insulation system, wrap up the whole building, can strengthen air-tightness effectively and reduce air leak as well as convectional heat loss.

Permeability of Breawarf l3 ayer breathable membrane

Reduce construction cost |

| Application of breathable membrane |

| Mainly used as underlay for pitched roof and enclosure protection for insulating layer of walls. |

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 1, when the basement buried depth is not large, you can use the digging method, once in place, and then press the first on the next, the order of construction.

- Q: What material is used for waterproofing of tarpaulin

- Polypropylene Coil is only suitable for use in the top, waterproofing membrane is mainly used for building walls, roof, and tunnels, highways, landfills, etc., to resist the external rain, if it is home improvement Waterproof with this is not good, with tar ingredients, pollution of the environment.

- Q: Roof membrane waterproof construction process, what should be noted that?

- Four do not: 1 surface can not afford sand 2 surface can not afford skin 3 surface is not crisp 4 does not crack

- Q: Nanning building waterproof material market where

- This depends on what you need packaging materials, and if it is some packaging rope or paper or process raw materials and other different materials to find a different place, generally sold outside the packaging is more like Nanning near the train station Or the trading market,

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q: There is no formaldehyde in the finished putty

- Visible putty powder and formaldehyde or a great relationship, but now many manufacturers have introduced environmentally friendly putty powder, not only environmentally friendly pollution-free important is also can control the air, there is a negative ion putty powder is the composition which contains tourmaline tourmaline, through And the water molecules in the air combined with the decomposition of negative ions to deal with the air, anion can be neutralized with formaldehyde into dust falling into the air, you can also remove the dust in the air, as well as enhance the metabolism of the function.

- Q: I would like to ask how to do in the warm water above,

- Rough housing or liquid with a good, airtight than the coil is good, all-pervasive, if there is a trachoma in the case of white do not see the white. If the building from the building if the first waterproof, finished product protection is a problem.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Third, according to personal experience, SBS membrane waterproof, as long as the quality of waterproof membrane clearance, and in accordance with the requirements of the strict implementation of the implementation, it can be said that the most assured and a roof waterproofing method. Remember: First, the material to cross the border (must be the real polyester carcass), and second, pay attention to the operation carefully in the construction. Just remember these two points, it will not appear too much problem.

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 4: coating waterproof layer coating evenly, the thickness of the product to meet the technical requirements, the general thickness of not less than 1.5mm not exposed at the end.

Send your message to us

Good Quality Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords