Three Layer Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

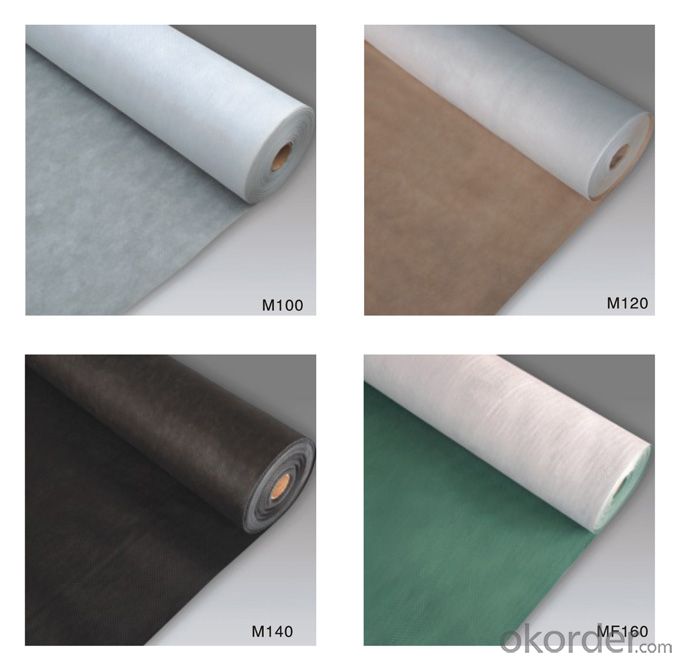

Three Layer Breathable Membrane

Breathable membrane is thermal laminated by the high polymer material in the middle layer . Paving on the top of the insulation system, it can strengthen the water tightness of the building, as well as to eliminate humidity inside the containment by the unique breath ability, thus to retain the duration of building effectively , playing a part in thermal insulation, energy conservation and living environmental improvement.

We pay high attention to the quality of products, advance production equipments, perfect detection means, sound ISO system, powerful ability on technical research and management formed the preeminent “ Shanquan” quality.

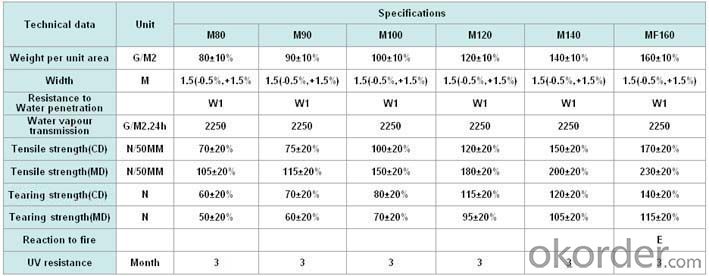

EN13859-1

- Q: Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q: A complete set of basement waterproof construction program

- First, the basement of the external walls of water leakage project engineering basement waterproofing standard GB50108-2001 "underground engineering waterproof technical specifications" secondary waterproof rating. Basement exterior wall waterproof structure with self-waterproof concrete plus coil waterproof, 50 thick polystyrene board protective layer.

- Q: How to do waterproof bathroom, construction process is what

- 4, closed water test. Closed water test, the highest point of the ground water can not be less than 2 cm, save at least 24 hours, observe the phenomenon of no leakage after the operator. If there is leakage, need to redo, and can not neglect.

- Q: Home improvement waterproofing problem

- 5, the kitchen is designed to be waterproof. In principle, there should be water and water treatment should be done to avoid the water pipe out of the problem, affecting the destruction of downstairs decorating

- Q: FRP finished brush on what can be waterproof do not fade

- On the surface of the gel coat it is, a lot of gel coat points, the specific performance of what you want, you can communicate with the supplier

- Q: Villa roof leakage what general reasons, what materials to remedy

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. First look at the roof there is no crack, the original waterproof layer is not aging, the roof of the original waterproof membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking, and roof On the gutter there is no clogging.

- Q: How can the toilet waterproof works fail?

- Use 755 new waterproof material can be painted three times. There is also a new type of waterproof material is water-like brush is also three times, you can go to the building materials market to see, you know.

- Q: Rigid (concrete) waterproof roofing shop SBS coil can brush a layer of waterproof paint before?

- Second, the completion of the construction of the membrane and the acceptance of qualified, should do the protection of finished products, it is recommended to use cement mortar to do protective layer, construction should pay attention to the surface should be smooth pressure, and set the surface sub-grid, 1 m2. If the use of block material to do the protective layer, the sub-grid area should not be greater than 100 square meters, sub-grid width should not be less than 20mm; if the use of fine stone concrete protective layer, the sub-grid area should not be greater than 36 square meters. Note: Regardless of which protective layer is used, a separation layer should be provided between the waterproofing layer and the protective layer.

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material is divided into four categories, namely, PVC material, aluminum gusset material, waterproof gypsum board, sauna board. Kitchen bathroom ceiling material 1: PVC material ????PVC is made of vinyl chloride in the role of the initiator made of thermoplastic resin, made of honeycomb shape. Suitable for use in damp places such as kitchen and toilet, because the PVC material ceiling in the life of a certain guarantee, you can use for 50 years without damage, while waterproof, heat insulation effect is good, but also has a certain noise Effect, in the kitchen is the best use of the ceiling material.

- Q: How does the waterproofing membrane work?

- 4, rolling the membrane: the first turn up the end of 1m long, with a long torch melting the bottom of the hot melt adhesive, the rapid paste fixed on the grassroots, and then re-harvest the rest of the volume. The gunmen stood on the paved webs, aligned with the corners of the rolls and the surface of the base layer with the flame of the long gun, and slowly rolled the edges by melting the hot melt. The web is pasted on the base;

Send your message to us

Three Layer Breathable Membrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords