1), Introduction of breathable membrane

Breathable Membrane is a water resistant membrane but with high vapour permeability, use as diffusion open roofing felts under pitched roof tile or vapour permeable barrier housewraps on timber frame walls

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties".

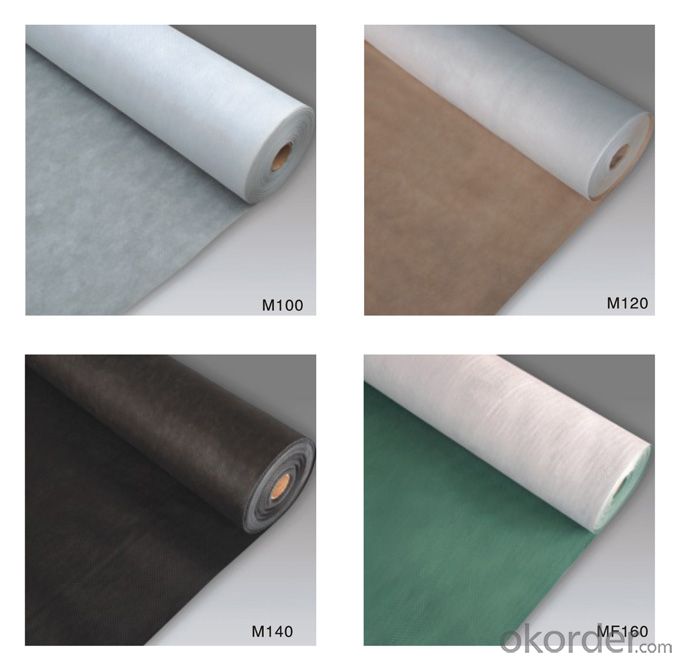

| 1 | 3-layers laminated | PP nonwoven+PE film+PP nonwoven |

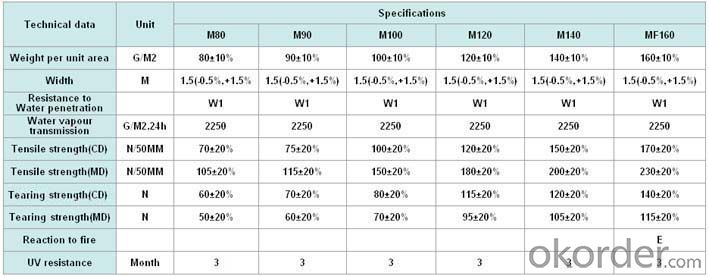

| 2 | Products range | 80g,90g,100g,120g,140g,160g/m2. |

| 3 | Roll size | 1.5m x 50m |

| 4 | Water resistant | Class W1 |

| 5 | SD-value | 0.02m |

| 6 | Vapor permeability | >2250g/m2/24h |

| 7 | UV resistant | >3month |

| 8 | Test to EN13859-1 | Pass -- CE mark available |

3)Key Features of breathable membrane :

| 1 | CE certificated, high quality with competitive price |

| 2 | Waterproof & vapour permeable |

| 3 | Excellent tensile and nail tear strength |

| 4 | Good flexibility and ductility |

| 5 | Light weight and thin, slip-resistant surface |

| 6 | Simple handling and easy to use |

| 7 | Energy saving |

| 8 | Long term durability |

| 9 | Totally recyclable |

| 10 | For both wall and roof applications |