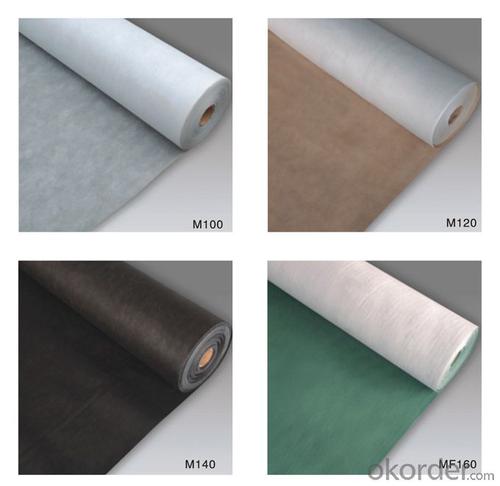

Breathable Membrane for Pitched Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | with pallets or carton box |

| Delivery Detail: | 15~30 days |

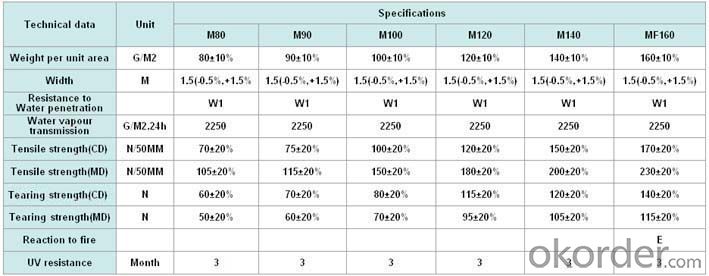

Specifications

breathable membrane for pitched roof

size 1.5*50m/roll

vapor permeable & waterproof

UV resistance

1) Introduction of breathable membrane for pitched roof

Breathable Membrane is a water resistant membrane but with high vapour permeability, use as diffusion open roofing felts under pitched roof tile or vapour permeable barrier housewraps on timber frame walls

Breather membrane functions as a weather-resistant barrier, preventing rain from getting into the roof or wall assembly while allowing water vapor to pass to the exterior.

Breather membrane may also serve as an air barrier if it is sealed carefully at seams.

Breathable Membrane have good "water resistance", good "water vapor permeability", and good "air barrier properties".

3)Key Features of breathable membrane for pitched roof

- Q: Bathroom first leveling or do waterproof, what is the difference

- 2. Grass-roots waterproof, materials, local conditions, with particular attention to the wall and root and other vulnerable parts of the leakage, should do some special waterproof, plugging treatment. Stir the waterproof material, the first layer of the coating should be waterproof material scraper evenly coated on the base surface, the thickness of 0.6mm or more, to be uniform, the first wall after the operation, from the inside out of the operation , Can not have local deposition, leaving no bubbles, strong bonding. Ground waterproof layer should be painted out of the bathroom door outside the 300 wide, should be higher than the ground 200, shower wall waterproof layer should be higher than the ground 1800mm. The next brushing direction is perpendicular to the last time. The last time the film semi-curing, throwing coarse sand particles, easy to combine with the cement mortar in the future. To be dry after a few days to do closed water test, observe no leakage side good.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Third, the mouth of the mouth, put pressure glue gun Cut the hose tube, fitted with a pointed nozzle, and then according to the size of the gap will be cut by 45 degrees angle. Install the glue gun.

- Q: What material is used for waterproofing of tarpaulin

- Regardless of the construction or finished products are toxic, due to organic materials, it will form a separation layer, partition structure of poor wear resistance, must be a protective layer of solid, not hollowing, but requires the base surface moisture content of less than 8% overlap requirements No interface to form a seamless body thickness control easy to control the local thickness difficult to control

- Q: Roof membrane waterproof construction process, what should be noted that?

- Foundation treatment to find leveling to pay attention Five to: 1 slope accurate, smooth drainage 2 surface is flat 3 strong 4 clean 5 dry

- Q: What material waterproofing can be mixed with cement sand

- Construction can be made with the waterproofing agent and cement made of waterproof mortar. The ratio of cement to sand is 2: 3, and the amount of waterproofing agent is 1% of the cement.

- Q: Js waterproof coating without powder can brushing

- impossible. JS waterproof coating must be added cement, because this waterproof coating with a certain proportion of cement. 1. JS plastic waterproof coating before the construction of the base surface treatment: the base must be strong, clean, smooth, moist; base surface pores, cracks and other shortcomings, first to use cement mortar to achieve the role of repair smooth; Angle to use the knife to use this tool to repair the shape of the semi-fillet; to ensure that the base surface is full of moisture, but no water;

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: I would like to ask how to do in the warm water above,

- Do not know why you are in the floor to do the top of the waterproof? The We are here in the northeast of the winter is very cold, are warm, no one to warm the ground to do the above water, I think you over and over again, ah, no need, every family is warm, you have to do waterproof in the above is afraid of soaking your floor or tiles Bubble? The If the pipe really leaked, did not use the waterproof, the first warm tube must be selected, followed by your shop is good or bad, workers, water, are very important, you focus on this line on the line

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 4: sauna board ????This is a dedicated wood panel for the sauna, but it can also be used in the kitchen and bathroom, generally degreased, with high temperature, not easy to deformation, health and environmental protection and other characteristics, even if there is a long time in the water Will not rot, usually painted in a layer of paint decoration, can make the overall ceiling more beautiful.

- Q: Waterproof material water leakage construction should pay attention to what

- 3, do the closed water test After the waterproof construction is completed, the water storage test. Will be blocked all the toilet outlet, the door at a pound of about 200mm high barrier, and then poured in the bathroom about 20mm ~ 30mm deep water, and 24 hours after the inspection of the walls and the ground around the leakage phenomenon , Waterproof test is to ensure the quality of the bathroom waterproofing the key, we must do. Such as after 24 hours without leakage as qualified. If you find a leak, you should immediately stop the water storage test, re-waterproof layer to improve the treatment, after passing the water test.

Send your message to us

Breathable Membrane for Pitched Roof

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords