One Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material, suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof film after coating. It is a new type of environmental friendly waterproof material without solvent.

Application:

Building roof

Concrete

Wall

Water Tank Structure

Floor(kitchen floor, bathroom floor ect)

Underground Tunnel

Sewerage Structure

Movement Joint

Wet Area, Pipes, Sewer & etc.

Advantages:

Water based and solvent based

Solid content above 80%

Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

Good splicing performance

Operate conveniently, low viscosity

Can splicing with concrete and many kinds board stuff

Will not change color after used

Apply for Roof,Swimming Pool,Tank and more

Specifications:

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

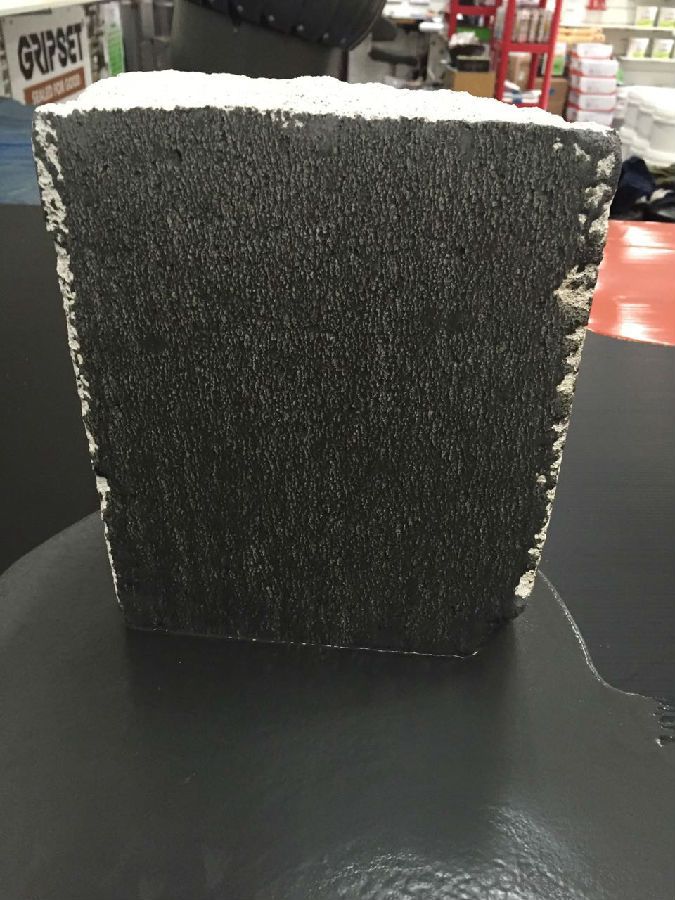

Images:

FAQ:

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed.

With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the

world. Warmly welcome your samples requirement or trail order.

- Q: What is the car waterproof sticker material?

- Engraving process car sticks A. knife engraving process: refers to the computer will be vector graphics input knife machine, the knife will be cut into a preset film shape, and then by hand will be different colors together Finished, and finally in the finished product posted on the surface of a layer of transparent transfer film, after the stickers to remove the stickers; due to knife car paste production process is complex, high cost of materials, currently only suitable for individual car and Che Youhui team Small customization

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: What material is used for waterproofing of tarpaulin

- Cement-based waterproof paste (such as the Swiss Sika) Product category Cement-based materials non-toxic, environmentally friendly, both in the construction process also Is formed after the harmless to humans and animals.

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Oriental rain rain waterproof how to

- 1, the East Yuhong waterproof coating quality assurance In the national waterproof products and technology market, rain rain waterproof material is unique, is the product of long-term demand for professional waterproof brand, long-term dominate in the waterproof market.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Need to waterproof the external walls, there are several programs. First, directly in the existing external walls of the main surface of the water treatment, the use of technology and materials due to different external finishes and different;

- Q: Finished house bathroom waterproof household acceptance should be how to accept?

- 2: waterproof layer should be extended from the ground to the wall, 250mm above the ground. Bathroom wall waterproof layer height of not less than 1800mm.

- Q: How does the waterproofing membrane work?

- The use of hot-melt method for waterproofing membrane construction, the following steps can be carried out: 1, before the grass-roots clean-up construction, and determine the dryness of grass-roots meet the construction requirements;

Send your message to us

One Component Polyurethane Waterproof Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords