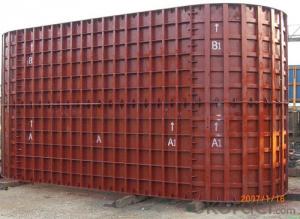

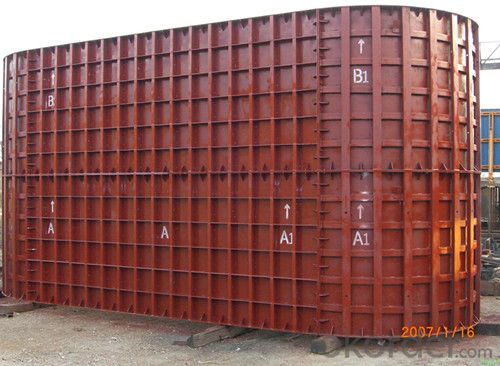

CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q: Can steel formwork be used in areas with extreme temperature variations?

- Steel formwork is indeed capable of being utilized in regions with significant temperature fluctuations. Thanks to its high strength-to-weight ratio and resistance to thermal changes, steel is well-suited for diverse conditions. It can endure both high and low temperatures without experiencing structural deformity or deterioration. Moreover, steel formwork delivers exceptional stability and durability, guaranteeing its ability to withstand the strain caused by extreme temperature fluctuations. However, it is crucial to take into account the effects of thermal expansion and contraction when employing steel formwork in areas with substantial temperature variations, as these factors may influence the precision of the formwork and the ultimate concrete structure. By considering proper design aspects and employing appropriate installation techniques, any potential issues arising from temperature variations can be effectively managed.

- Q: What are the typical fire resistance ratings of steel formwork systems?

- The typical fire resistance ratings of steel formwork systems can vary depending on several factors such as the type of steel used, the thickness of the steel, and the overall design and construction of the formwork system. However, in general, steel formwork systems are known for their high fire resistance properties. Steel is a non-combustible material, which means it does not contribute to the spread or intensity of fire. It has a high melting point and does not ignite or release flammable gases when exposed to fire. As a result, steel formwork systems can withstand high temperatures and provide excellent fire resistance. In many cases, steel formwork systems are designed to meet or exceed specific fire resistance ratings specified by building codes and regulations. These ratings are typically expressed in terms of a time period, such as 1 hour, 2 hours, or more, which represents the duration for which the formwork system can maintain its structural integrity and protect against fire. The fire resistance ratings of steel formwork systems can be further enhanced by incorporating additional fire protection measures such as fire-resistant coatings or insulation materials. These measures can provide an extra layer of protection and increase the overall fire resistance of the formwork system. It is important to note that fire resistance ratings can also depend on other factors such as the presence of fire-resistant materials in the surrounding structure and the overall fire safety measures implemented in the building. Therefore, it is crucial to consult with structural engineers, architects, and fire safety experts to determine the specific fire resistance requirements and ratings for steel formwork systems in a particular construction project.

- Q: How does steel formwork affect the overall sound insulation of a building?

- Steel formwork does not directly affect the overall sound insulation of a building. Sound insulation primarily depends on the quality and design of the walls, floors, and ceilings, which are independent of the formwork material. However, steel formwork may indirectly impact sound insulation during the construction phase. Steel formwork is known for its rigidity and strength, which helps in ensuring accurate and precise concrete pouring. This precise construction technique can minimize the gaps and imperfections that may occur during the casting of concrete. As a result, steel formwork can contribute to creating a smoother and more uniform concrete surface, reducing the chances of sound leakage through cracks or joints. Furthermore, steel formwork can be used to create smooth and even surfaces, which can facilitate the installation of soundproofing materials such as acoustic panels or insulation. These additional soundproofing measures, when incorporated during the construction phase, can enhance the overall sound insulation of the building. It's important to note that while steel formwork can indirectly influence sound insulation during construction, the primary factors affecting sound insulation are the materials and techniques used for constructing walls, floors, and ceilings. Architectural design, insulation materials, and sealing techniques play a crucial role in achieving optimal sound insulation levels.

- Q: What are the different surface treatments available for steel formwork panels?

- Steel formwork panels can be treated with various surface treatments to enhance their durability and performance. Some common options include: 1. Galvanization: By immersing the panels in molten zinc, a protective layer is formed on the surface. This treatment is ideal for outdoor and highly corrosive environments due to its excellent corrosion resistance. 2. Powder coating: A dry powder coating is applied to the steel surface and then cured under heat. This provides a durable and visually appealing finish with resistance to corrosion, abrasion, and chemicals. Additionally, a wide range of colors and textures can be achieved. 3. Epoxy coating: Liquid epoxy coatings are applied to the steel surface and then cured to create a hard and protective layer. This treatment offers exceptional resistance to corrosion, chemicals, and abrasion, making it suitable for harsh conditions. 4. Paint: Various types of paint can be used to create a protective layer and improve aesthetics. The level of resistance to corrosion, UV radiation, and wear depends on the specific paint used. 5. Shot blasting: High-speed steel shot or grit particles are used to blast the surface of the steel formwork panels. This process removes rust, scale, and contaminants, creating a clean and roughened profile that enhances the adhesion of subsequent coatings. 6. Hot-dip aluminizing: The panels are immersed in molten aluminum to form a thin layer on the surface. This treatment offers excellent corrosion resistance and heat reflectivity. These surface treatments provide different levels of protection against corrosion, abrasion, chemicals, and environmental factors. The choice of treatment depends on the specific application and desired durability.

- Q: How does steel formwork handle concrete bleeding and segregation?

- Steel formwork has a reputation for effectively managing concrete bleeding and segregation. Bleeding occurs when water in the concrete mixture rises to the surface, leaving a layer of water on top. Segregation, on the other hand, happens when the solid particles in the concrete mixture separate from the water, causing an uneven distribution. To minimize bleeding and segregation, steel formwork provides a sturdy structure that holds the concrete in place during pouring and curing. The strong construction and tight joints of steel formwork prevent any leaks or seepage, resulting in reduced bleeding. Moreover, steel formwork allows for better control over the placement and compaction of the concrete. The smooth and non-absorbent surface of steel formwork facilitates a uniform distribution of the concrete mixture, minimizing the risk of segregation. Additionally, using steel formwork enables proper vibration and consolidation of the concrete, eliminating any voids or air pockets that could contribute to segregation. Furthermore, steel formwork ensures stability during the curing process, preventing significant movement of the concrete. This stability helps avoid disturbances that could lead to bleeding or segregation. In conclusion, steel formwork is highly effective in managing concrete bleeding and segregation due to its rigid structure, tight joints, smooth surface, and stability. Its use promotes a more consistent and consolidated placement of concrete, resulting in a higher quality finished product.

- Q: What are the different safety precautions to be followed during steel formwork installation?

- Some of the safety precautions to be followed during steel formwork installation include wearing appropriate personal protective equipment such as hard hats, safety glasses, and steel toe boots. Ensuring that the work area is clear of any hazards or obstructions that could pose a tripping or falling hazard. Using proper lifting techniques and equipment when handling heavy steel formwork components to prevent injuries. Adhering to proper electrical safety procedures when working with power tools or equipment near electrical sources. Following manufacturer's instructions and guidelines for the proper installation and use of steel formwork. Regularly inspecting the formwork for any signs of damage or defects and addressing them promptly. Additionally, proper training and supervision of workers should be provided to ensure they are knowledgeable about and adhere to all safety precautions.

- Q: What are the common connection methods for steel formwork?

- The common connection methods for steel formwork include welding, bolting, and using connecting plates or brackets.

- Q: How does steel formwork affect the construction schedule?

- Steel formwork can have a significant impact on the construction schedule. One of the main advantages of steel formwork is its ability to provide a high level of stability and strength, allowing for faster construction processes. This means that the overall construction time can be reduced as compared to traditional formwork methods. Steel formwork is also highly durable and can withstand multiple uses, which means that it can be reused for future projects. This reduces the time and cost associated with procuring and assembling new formwork for each project, further contributing to the efficiency of the construction schedule. Additionally, steel formwork allows for precise and accurate construction, resulting in a higher quality finish. This reduces the need for rework and corrections, ultimately saving time and keeping the project on schedule. Furthermore, steel formwork is known for its flexibility and adaptability. It can be easily adjusted and modified to accommodate changes in design or construction requirements. This allows for a smoother workflow and minimizes delays that may occur due to design changes. However, it is worth noting that the initial setup and installation of steel formwork may require more time and resources compared to other formwork systems. The design and fabrication process for steel formwork can be more complex, requiring careful planning and coordination. Therefore, it is essential to consider these factors during the project planning phase to ensure that the construction schedule is not adversely affected. Overall, steel formwork can greatly expedite the construction schedule by providing strength, durability, precision, and adaptability. However, it is crucial to carefully evaluate the specific project requirements and resources available to ensure the optimal use of steel formwork and minimize any potential disruptions to the construction schedule.

- Q: Can steel formwork be customized for specific projects?

- Indeed, specific projects can have steel formwork customized to their needs. Steel formwork, as a construction material, is versatile and adaptable. It can be easily modified to meet the specific requirements of a project through cutting, bending, and welding, allowing for various shapes and sizes to accommodate different architectural and structural designs. This enables the creation of one-of-a-kind and intricate concrete structures. Furthermore, steel formwork's easy assembly and dismantling make it suitable for projects that require frequent changes or adaptations. Its modular nature allows for effortless reconfiguration and customization, saving time and effort during construction. Additionally, steel formwork can undergo surface treatment to increase its durability and resistance to corrosion. This ensures its ability to withstand the harsh conditions found on different construction sites, making it suitable for a broad range of projects, including high-rise buildings, bridges, tunnels, and other complex structures. Overall, steel formwork provides significant flexibility and adaptability, making it a superb choice for construction projects of all sizes and types. Its capacity to accommodate various shapes, sizes, and designs allows for customization and tailoring to meet specific project requirements.

- Q: Can steel formwork be used in architectural concrete projects?

- Yes, steel formwork can be used in architectural concrete projects. Steel formwork offers several advantages such as durability, reusability, and the ability to create complex shapes and designs. It provides a smooth and consistent finish to the concrete surface, making it suitable for architectural applications where aesthetics are important. Additionally, steel formwork can withstand high pressure and load, allowing for the construction of large and structurally sound concrete elements.

Send your message to us

CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches