All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

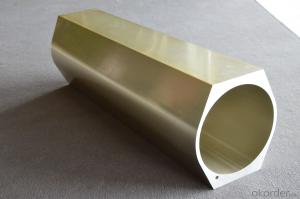

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

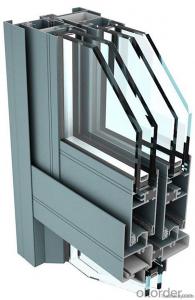

What surface finishes are commonly applied to aluminum profiles, and how do they affect performance?

Some common surface finishes applied to aluminum profiles include anodizing, powder coating, and polishing.

Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum, increasing corrosion resistance and durability. It also provides a wide range of color options.

Powder coating involves applying a dry powder to the aluminum surface, which is then cured to form a durable and attractive finish. It offers excellent resistance to weathering, scratching, and fading.

Polishing gives the aluminum profile a smooth and reflective surface, enhancing its aesthetic appeal. However, this finish does not provide as much protection against corrosion as anodizing or powder coating.

The choice of surface finish can impact the performance of aluminum profiles. Anodizing and powder coating enhance the durability and resistance to environmental factors, making them ideal for applications where the profiles will be exposed to harsh conditions. Polishing, on the other hand, is more commonly used in applications where aesthetics are prioritized over protection.

What are the design considerations for using aluminum profiles in the production of energy-efficient lighting fixtures?

Some design considerations for using aluminum profiles in the production of energy-efficient lighting fixtures include the material's lightweight nature, which allows for easier installation and handling. Aluminum also has excellent heat dissipation properties, ensuring efficient thermal management for the lighting fixtures. The profiles can be easily customized and shaped to accommodate various designs, allowing for versatile and aesthetically pleasing lighting solutions. Additionally, aluminum is a sustainable and recyclable material, aligning with the goal of creating environmentally friendly lighting fixtures.

How do you connect or join aluminum profiles securely for various applications?

One common method to securely connect or join aluminum profiles for various applications is through the use of T-slot connectors. These connectors feature a unique shape that fits into the T-slot grooves found on aluminum profiles, providing a secure and sturdy connection. Additionally, bolts or screws can be used to further strengthen the joint. Another option is welding, where aluminum profiles can be fused together using specialized welding techniques to create a permanent and robust connection. Depending on the specific requirements and preferences, other methods such as adhesive bonding or mechanical fasteners may also be used to securely connect aluminum profiles.

What is the extrusion process for aluminum profiles?

The extrusion process for aluminum profiles is a manufacturing technique where a heated aluminum billet is forced through a die to create a desired shape or profile. This process involves applying high pressure to the aluminum billet, which is then pushed through the die to produce a continuous length of the desired profile. The resulting aluminum profile can be used in various industries for applications such as construction, automotive, and aerospace.

Wholesale Aluminum Profiles from supplier in Lesotho

With our strong backing from CNBM, a Fortune Global 500 company, you can have confidence in the quality and reliability of our Aluminum Profiles products. We have a wide range of options available, including standard profiles as well as customized solutions to meet your specific project requirements.

Our experienced team is well-equipped to handle all aspects of your procurement process, from sales and quotations to technical support. We understand the unique challenges and demands of the Lesotho market, and we can provide tailored solutions that will help you achieve success in your projects.

By choosing us as your Aluminum Profiles supplier, you can expect excellent customer service and support throughout your project. We are committed to ensuring a seamless and efficient procurement experience, and our experts are always available to provide guidance and assistance.

Don't settle for anything less than the best when it comes to your Aluminum Profiles needs in Lesotho. Trust in our expertise, reliable products, and top-notch customer service to help you achieve your project goals. Contact us today to learn more about how we can meet your Aluminum Profiles procurement needs in Lesotho.

Our experienced team is well-equipped to handle all aspects of your procurement process, from sales and quotations to technical support. We understand the unique challenges and demands of the Lesotho market, and we can provide tailored solutions that will help you achieve success in your projects.

By choosing us as your Aluminum Profiles supplier, you can expect excellent customer service and support throughout your project. We are committed to ensuring a seamless and efficient procurement experience, and our experts are always available to provide guidance and assistance.

Don't settle for anything less than the best when it comes to your Aluminum Profiles needs in Lesotho. Trust in our expertise, reliable products, and top-notch customer service to help you achieve your project goals. Contact us today to learn more about how we can meet your Aluminum Profiles procurement needs in Lesotho.