Aluminum Frame Extrusion Profiles - Alloy 6063, 6061, 6005 or Custom Choice Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

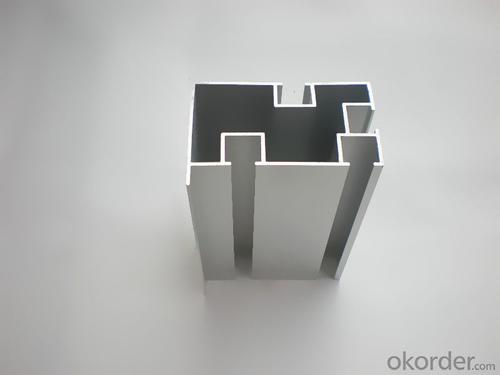

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

- Q: How do you protect aluminum profiles from scratching or damage?

- There are multiple methods available for safeguarding aluminum profiles against scratches or damage. To begin with, a commonly used approach involves applying a protective coating or finish. This can be accomplished by utilizing paints, lacquers, or powder coatings that serve as a barrier between the aluminum surface and external elements. These coatings not only enhance the appearance but also offer protection against scratches, corrosion, and other forms of damage. Another effective temporary solution is the utilization of protective film or tape. These films or tapes can be directly applied onto the aluminum profiles, acting as a shield. Generally transparent, these films can be easily peeled off once the profiles are installed or ready for use. A different technique involves handling and transporting the aluminum profiles with caution. This entails the use of appropriate handling equipment, such as gloves, to avoid direct contact with the surface. Additionally, the use of protective packaging materials like bubble wrap or foam can provide cushioning during transportation, preventing scratches or dents. Regular cleaning and maintenance of the aluminum profiles is also crucial. Dust, dirt, and debris can act as abrasives, causing scratches over time. Cleaning with a soft cloth or sponge and mild detergent on a regular basis can help eliminate these particles and preserve the profile's appearance. Lastly, implementing proper storage practices is of utmost importance. Storing aluminum profiles in a dry and clean environment, away from sharp objects or heavy items, can minimize the risk of scratching or damage. The use of racks or shelves with protective padding can provide an additional layer of protection. By adhering to these measures, aluminum profiles can be effectively safeguarded against scratches or damage, ensuring their durability and preserving their aesthetic appeal.

- Q: Can aluminum profiles be used in transportation and logistics applications?

- Aluminum profiles find common usage in transportation and logistics applications, owing to their lightweight yet robust nature. This makes them an ideal choice for various components in the industry. Within the automotive sector, aluminum profiles are employed in the production of car frames, chassis, and body panels. Their lightweight quality aids in reducing vehicle weight, leading to enhanced fuel efficiency and lower emissions. Moreover, aluminum profiles exhibit excellent resistance to corrosion, ensuring vehicle longevity even in harsh environmental conditions. The aerospace industry heavily relies on aluminum profiles for the construction of aircraft structures, including wings, fuselage, and landing gear. The high strength-to-weight ratio of these profiles allows for increased payload capacity and improved fuel efficiency. Furthermore, aluminum profiles can withstand extreme temperature fluctuations and possess good electrical conductivity, rendering them suitable for diverse aerospace applications. In the logistics sector, aluminum profiles are utilized in the creation of cargo containers, pallets, and storage racks. Their lightweight nature facilitates easy handling and transportation of goods. Additionally, these profiles offer high resistance to rust and corrosion, ensuring the durability of logistics equipment, even in humid or corrosive environments. Moreover, aluminum profiles can be easily customized and fabricated to meet specific design requirements in transportation and logistics applications. Their extrudability into various shapes and sizes allows for versatility in design and functionality. Furthermore, aluminum profiles offer flexibility in assembly and maintenance, as they can be joined using different methods like welding or fastening. To sum up, the lightweight, strong, corrosion-resistant, and versatile properties of aluminum profiles make them highly suitable for transportation and logistics applications. They confer various benefits, such as improved fuel efficiency, increased payload capacity, and durability in harsh environments. Consequently, aluminum profiles find extensive use in the automotive, aerospace, and logistics industries for various components, thereby contributing to the efficiency and reliability of transportation and logistics systems.

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: Where is the aluminum profile market in Tianjin?

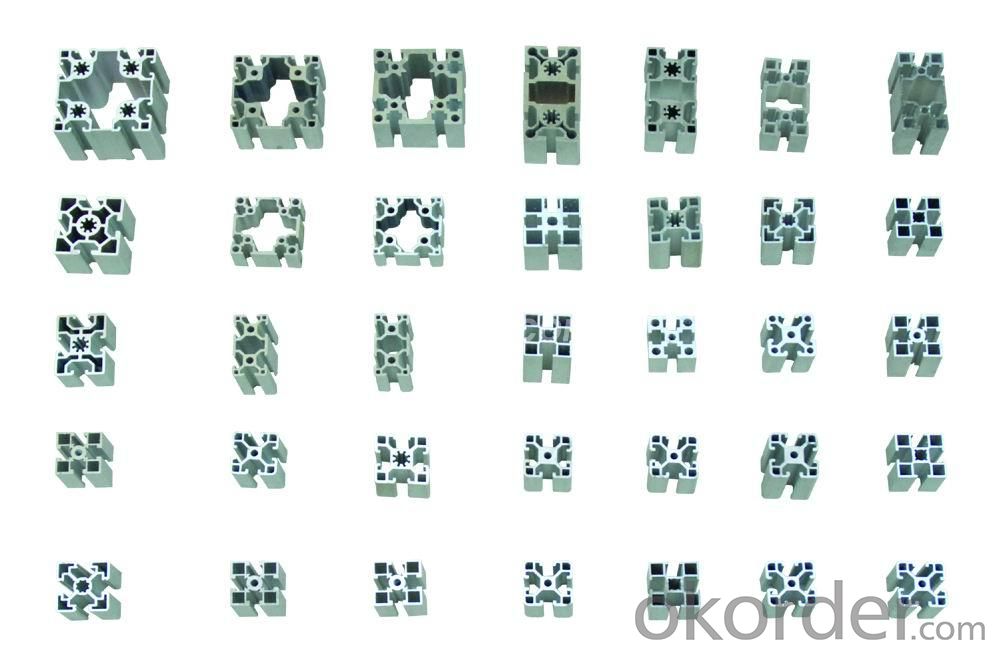

- Industrial aluminium profile standard profile:1530156015901640, 2020204020803030, 30R arc, 3030W 3030, 3030R, 3030RQ, 3060309030150, 4040A, 4040Q, 4040L4040W, 4040Z, 40R arc, 40 right angle, 4060Q, 4060L, 4060Z, 4080, 4080L, 4080W, 8080, 8080W, 606080120100100, 1201204012045454545L 4545Q 4545W 45909090 9090W 45R 4560 4560W 501005050501006060 6060L arc 4545RQ (1530-120120 Series) line industrial profiles and accessories can be assembled into processing products: tool rack (car), operation table, special tool cart, line table, product display, LCD panel, sun room, display cabinets, display rack, mechanical seal cover, shelves, product testing equipment, non-standard equipment, industrial fence, plotter, testing equipment, laboratory equipment, biological machine, labeling machine, production line, motor rotor bracket, electronic products production line, production line, line table, equipment protection barrier, LCD panel production equipment

- Q: How does the aluminum profile bevel come round?

- If the stitching aluminum alloy model is the same, then the cutting angle must be 45 degrees, it is possible to splice.

- Q: Can aluminum profiles be used for solar power systems?

- Yes, aluminum profiles can be used for solar power systems. Aluminum is a widely used material in the construction of solar panels and their support structures. It is preferred for its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum profiles are often used for the framing and mounting of solar panels, as they provide structural stability and durability. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for solar power systems.

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Are aluminum profiles suitable for use in architectural lighting fixtures?

- <p>Yes, aluminum profiles are commonly used for architectural lighting fixtures due to their durability, lightweight nature, and excellent heat dissipation properties. They offer design flexibility and can be easily shaped and machined to fit various lighting designs. Additionally, aluminum's resistance to corrosion makes it ideal for both indoor and outdoor lighting applications.</p>

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: How do aluminum profiles perform in terms of dimensional stability?

- Aluminum profiles are known for their excellent dimensional stability. Due to the inherent properties of aluminum, such as its low coefficient of thermal expansion and high strength-to-weight ratio, these profiles maintain their shape and dimensions even under fluctuating temperatures and loads. This makes them highly reliable for applications that require precise and consistent dimensions, such as in construction, automotive, and aerospace industries. Additionally, aluminum profiles can be extruded to precise tolerances, further enhancing their dimensional stability. Overall, aluminum profiles offer exceptional performance in terms of dimensional stability, ensuring that the desired specifications are maintained over time.

Send your message to us

Aluminum Frame Extrusion Profiles - Alloy 6063, 6061, 6005 or Custom Choice Aluminium Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords