All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you optimize the lifecycle costs and sustainability of projects involving aluminum profiles in various industries?

To optimize the lifecycle costs and sustainability of projects involving aluminum profiles in various industries, several strategies can be implemented.

Firstly, it is crucial to consider the entire lifecycle of the project, from raw material extraction to disposal. This holistic approach helps identify opportunities to minimize energy consumption, reduce waste generation, and ensure responsible sourcing of aluminum profiles.

Efficient design and engineering practices can also contribute to cost optimization and sustainability. By optimizing the design of aluminum profiles, such as reducing material usage and incorporating recyclability, the overall energy consumption and environmental impact can be reduced.

Implementing effective maintenance and repair programs can extend the lifespan of aluminum profiles, reducing the need for replacements and lowering costs. Regular inspections and preventive maintenance can prevent premature failures and ensure the longevity of the profiles.

Furthermore, incorporating circular economy principles, such as recycling and reusing aluminum profiles at the end of their lifecycle, can significantly enhance sustainability. Employing recycling initiatives ensures the recovery of valuable materials, reduces waste, and decreases the demand for virgin aluminum production.

Collaboration with suppliers and stakeholders is vital in optimizing lifecycle costs and sustainability. Engaging with suppliers who prioritize sustainable practices and offer environmentally-friendly options can contribute to the overall sustainability of the project.

Lastly, monitoring and evaluating the project's environmental performance through key performance indicators (KPIs) can provide insights into areas that require improvement. Regular assessments and continuous improvement initiatives enable the identification of inefficiencies and the implementation of targeted measures to optimize lifecycle costs and enhance sustainability.

How do you ensure the quality and consistency of aluminum profiles during manufacturing?

To ensure the quality and consistency of aluminum profiles during manufacturing, several measures can be taken. Firstly, strict quality control procedures should be implemented at every stage of the manufacturing process, including raw material inspection, extrusion, surface treatment, and finishing. Regular inspections and testing should be conducted to identify any defects or deviations from the specified standards.

Additionally, proper maintenance and calibration of manufacturing equipment is crucial to maintain consistent product quality. Regular checks and adjustments should be made to ensure accurate dimensions, tolerances, and surface finishes.

Furthermore, implementing a comprehensive quality management system, such as ISO 9001, can help establish standardized processes and documentation. This includes setting quality objectives, conducting internal audits, and continuously improving the manufacturing processes.

Collaboration with suppliers is also important to ensure the quality of raw materials. Establishing strong relationships and conducting regular audits of suppliers' quality systems can help ensure consistent material quality.

Lastly, providing adequate training to employees involved in the manufacturing process is essential. Educating them about quality standards, procedures, and the importance of their role in maintaining consistent quality can significantly impact the overall quality of aluminum profiles.

What is the role of aluminum profiles in the transportation industry?

Aluminum profiles play a crucial role in the transportation industry by providing lightweight and durable materials for various applications. They are commonly used in the construction of vehicles, such as cars, trucks, buses, and trains, to reduce overall weight and improve fuel efficiency. Aluminum profiles are also utilized in the manufacturing of aerospace components, such as aircraft frames and panels, due to their high strength-to-weight ratio. Additionally, these profiles offer excellent corrosion resistance, making them ideal for outdoor and marine transportation applications.

Wholesale Aluminum Profiles from supplier in Andorra

Our team of experts is dedicated to understanding your specific requirements and providing customized solutions for your Aluminum Profiles needs. Whether you are in the construction, automotive, or any other industry that requires Aluminum Profiles, we have the knowledge and resources to meet your demands.

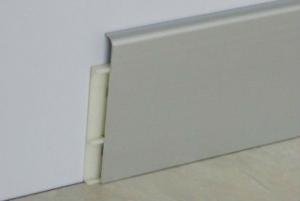

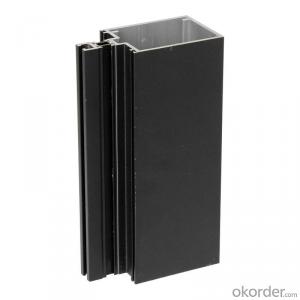

We offer a wide range of Aluminum Profiles products, including extruded profiles, customized profiles, and standard profiles. Our products are manufactured using high-quality materials and advanced production techniques to ensure durability and reliability.

In addition to supplying Aluminum Profiles, we also provide sales and technical support services. Our experienced sales team is available to assist you with product selection, pricing, and any other inquiries you may have. We can also provide technical support, including assistance with installation, maintenance, and troubleshooting.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer competitive prices and efficient procurement services for Aluminum Profiles in Andorra.

Customer satisfaction is our top priority, and we strive to exceed your expectations in terms of quality, service, and value. We are committed to building long-term relationships with our clients and becoming your trusted partner for Aluminum Profiles in Andorra.

Contact us today to discuss your Aluminum Profiles requirements and discover how we can provide the expertise and support you need for your projects in Andorra.

We offer a wide range of Aluminum Profiles products, including extruded profiles, customized profiles, and standard profiles. Our products are manufactured using high-quality materials and advanced production techniques to ensure durability and reliability.

In addition to supplying Aluminum Profiles, we also provide sales and technical support services. Our experienced sales team is available to assist you with product selection, pricing, and any other inquiries you may have. We can also provide technical support, including assistance with installation, maintenance, and troubleshooting.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer competitive prices and efficient procurement services for Aluminum Profiles in Andorra.

Customer satisfaction is our top priority, and we strive to exceed your expectations in terms of quality, service, and value. We are committed to building long-term relationships with our clients and becoming your trusted partner for Aluminum Profiles in Andorra.

Contact us today to discuss your Aluminum Profiles requirements and discover how we can provide the expertise and support you need for your projects in Andorra.