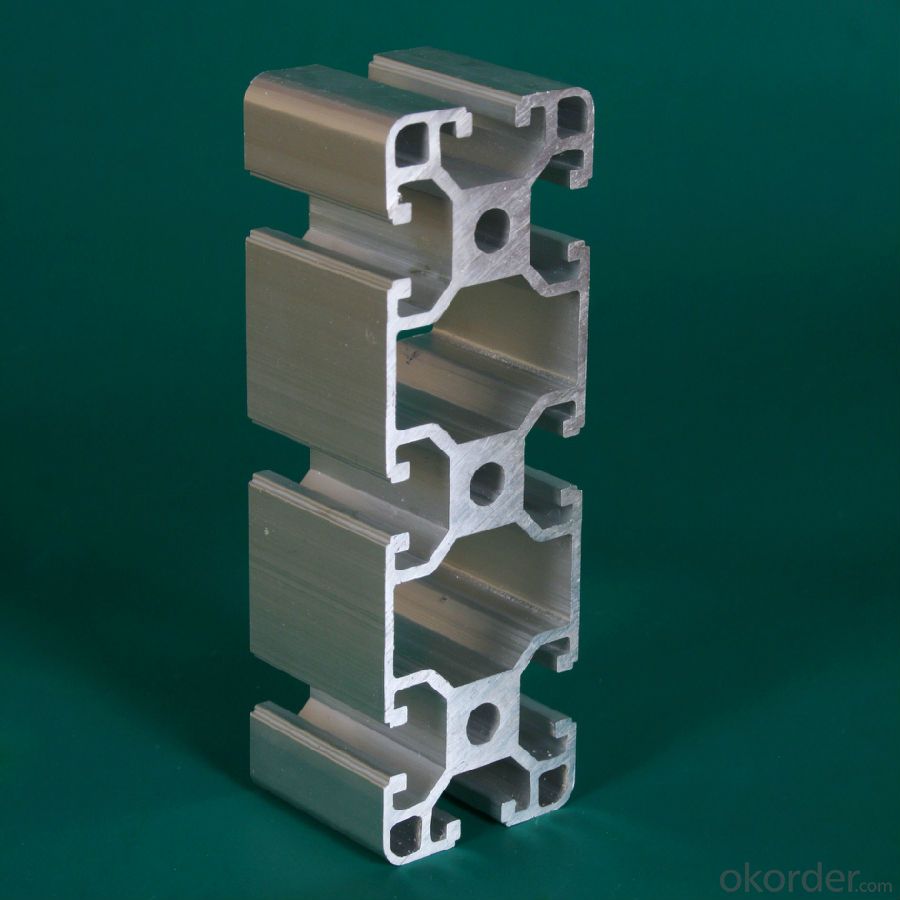

China Powder Coated Aluminum Profiles - Alloy 6063 Aluminium Extrusion Profiles for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6063 Aluminium Extrusion Profiles For Construction |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: What are the vibration damping properties of aluminum profiles?

- Aluminum profiles boast outstanding capabilities in mitigating vibrations. With their impressive ratio of stiffness to mass, aluminum profiles efficiently absorb and disperse vibrations, resulting in decreased magnitude and prevention of transmission to nearby structures. This particular attribute renders aluminum profiles highly suitable for industries like aerospace, automotive, and construction, where vibration management is of utmost importance. The inherent damping properties of aluminum profiles aid in reducing noise, minimizing damage, and guaranteeing structural stability. Moreover, aluminum's capacity to damp vibrations further elevates the overall comfort and safety of diverse products and structures.

- Q: Are there any specific requirements for transporting and storing aluminum profiles?

- Yes, there are specific requirements for transporting and storing aluminum profiles. Aluminum profiles should be handled with care to prevent any damage or deformation. During transportation, they should be properly secured to avoid shifting or falling. It is recommended to use protective packaging and cushioning materials to prevent scratches or dents. When storing aluminum profiles, they should be kept in a clean and dry area to prevent corrosion. It is advisable to stack them horizontally or on racks to avoid bending or warping. Additionally, they should be stored away from direct sunlight and extreme temperatures.

- Q: What are the different anodizing colors available for aluminum profiles?

- There are several different anodizing colors available for aluminum profiles, including clear, black, bronze, gold, and champagne.

- Q: How do aluminum profiles handle extreme weather conditions?

- Aluminum profiles possess exceptional durability and resilience, making them highly adept at tackling extreme weather conditions. Their inherent resistance to corrosion allows them to endure harsh weather elements like heavy rain, snow, temperature fluctuations, and intense UV radiation without succumbing to deterioration or corrosion. A key characteristic of aluminum is its ability to form a protective oxide layer, known as aluminum oxide, on its surface. This layer acts as a natural barrier, shielding the metal from moisture, salt, and other corrosive agents found in the atmosphere. Consequently, aluminum profiles remain unaffected by rain or snow, and they do not rust or corrode like other metals. Additionally, aluminum's thermal conductivity enables it to rapidly dissipate heat, preventing any harm caused by extreme temperature changes. Regardless of exposure to scorching heat or freezing cold, aluminum profiles undergo minimal expansion and contraction, which helps maintain their structural integrity and prevents warping or cracking. Furthermore, aluminum profiles can withstand high wind loads, making them suitable for areas prone to hurricanes, tornadoes, or strong gusts. Their lightweight yet sturdy composition allows them to endure significant pressure without bending or breaking. Regarding UV radiation, aluminum profiles exhibit excellent resistance to fading and discoloration. They can effectively withstand prolonged exposure to sunlight without losing their original color or surface finish. This renders them an ideal choice for outdoor applications, such as windows, doors, and facades, where they retain their visual appeal and structural soundness even in extreme weather conditions. In summary, aluminum profiles display remarkable durability, corrosion resistance, thermal stability, and resistance to UV radiation, enabling them to effectively handle and withstand the challenges presented by extreme weather conditions.

- Q: This question asks whether aluminum profiles can be joined using welding or bolting methods.

- <p>Yes, aluminum profiles can be both welded and bolted together. Welding aluminum requires specific techniques and equipment due to its high thermal conductivity, but it is possible and results in a strong joint. Bolting is a common method for joining aluminum profiles, as it is quick, easy, and does not require melting the material. It is important to use appropriate hardware and techniques to ensure a secure and durable connection.</p>

- Q: Can aluminum profiles be used in electrical switchgear manufacturing?

- Yes, aluminum profiles can be used in electrical switchgear manufacturing. Aluminum profiles are lightweight, yet strong and durable, making them an ideal choice for constructing switchgear cabinets. They offer excellent corrosion resistance, which is essential for protecting electrical components from moisture and other environmental factors. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for efficient and cost-effective manufacturing processes.

- Q: Xi'an XAC aluminum sales site.

- Chongqing aluminum is also good ah, Dadukou there

- Q: This question asks if aluminum profiles can be utilized in sustainable construction projects and seeks an explanation of their application.

- <p>Yes, aluminum profiles can be used for green building projects. They are valued for their durability, recyclability, and energy efficiency. Aluminum profiles are lightweight, which reduces the load on structures and can contribute to energy savings in heating and cooling. They also have high thermal conductivity, which can be beneficial for heat transfer in building systems. Additionally, aluminum is 100% recyclable, meaning it can be repurposed without losing its properties, reducing waste and the need for new raw materials. This recyclability aligns with the principles of sustainable construction by promoting a circular economy and reducing the environmental impact of building materials.</p>

- Q: Can aluminum profiles be used for creating lighting fixtures?

- Indeed, lighting fixtures can be fashioned using aluminum profiles. The lightweight quality, durability, and resistance to corrosion render aluminum a favored material for such fixtures. Moreover, its malleability and feasibility for machining make it appropriate for crafting diverse designs and styles of lighting fixtures. Further, aluminum profiles can undergo powder coating or anodization to enrich their visual allure and furnish supplementary safeguard against deterioration. The adaptability and aesthetic charm of aluminum designate it as an optimal selection for producing lighting fixtures across an extensive array of environments, encompassing residential, commercial, and industrial settings.

- Q: How do you clean and maintain aluminum profiles?

- To clean and maintain aluminum profiles, you can start by removing any loose debris or dirt using a soft brush or cloth. Then, prepare a mixture of mild soap or detergent with warm water. Gently scrub the profiles using this solution, ensuring to reach all the nooks and corners. Rinse thoroughly with clean water, and dry the profiles with a soft cloth. To maintain their shine, you can apply a small amount of aluminum polish or a non-abrasive metal cleaner, following the manufacturer's instructions. Regularly inspect the profiles for any signs of damage or corrosion, and promptly address any issues to prevent further deterioration.

Send your message to us

China Powder Coated Aluminum Profiles - Alloy 6063 Aluminium Extrusion Profiles for Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords