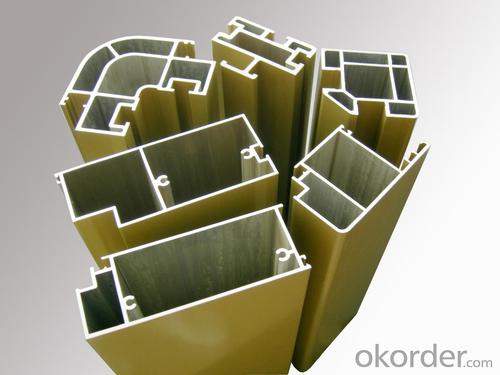

Aircraft Aluminum Extrusion Profiles - Alloy 6060 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6060 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Are aluminum profiles suitable for curtain walls and facades?

- Yes, aluminum profiles are highly suitable for curtain walls and facades. Aluminum is a lightweight and durable material that offers excellent strength, corrosion resistance, and design flexibility. It can be easily fabricated into various shapes and sizes, allowing for intricate and modern architectural designs. Additionally, aluminum profiles can accommodate large glass panels, providing ample natural light and enhancing the aesthetic appeal of buildings.

- Q: Are aluminum profiles suitable for constructing railings or staircases?

- <p>Yes, aluminum profiles are commonly used for railings and staircases due to their strength, durability, and low maintenance requirements. They offer a modern aesthetic and are resistant to corrosion, making them ideal for both indoor and outdoor applications. Aluminum profiles can be easily customized to fit various designs and can be powder-coated or anodized for enhanced visual appeal and protection against the elements.</p>

- Q: What are the different cutting options available for aluminum profiles?

- Some of the different cutting options available for aluminum profiles include sawing, shearing, laser cutting, and waterjet cutting. Each method has its advantages and is chosen based on factors such as precision requirements, budget, material thickness, and production volume.

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- respectively60 of the cross section is larger than 50 1cm, much stronger. The glass gap that can be installed is also larger

- Q: This question asks for methods to avoid corrosion on aluminum profiles during the installation process.

- <p>To prevent corrosion on aluminum profiles during installation, follow these steps: Use high-quality aluminum that has a protective oxide layer. Ensure the installation environment is dry and clean. Avoid contact with corrosive substances like acids or alkalis. Apply a protective coating or sealant if the profiles will be exposed to harsh environments. Use stainless steel or corrosion-resistant fasteners. Regularly inspect and clean the profiles to remove any dirt or debris that could lead to corrosion. Proper installation techniques and maintenance can significantly reduce the risk of corrosion on aluminum profiles.</p>

- Q: This question asks for a list of various roofing systems that incorporate the use of aluminum profiles.

- <p>Aluminum profiles are used in several types of roofing systems for their durability, lightweight, and corrosion resistance. Some common types include: 1. Standing Seam Roofing: Known for its sleek, clean appearance and watertight properties. 2. Aluminum Shingle Roofing: Mimics the look of traditional shingles but with the benefits of aluminum. 3. Metal Tile Roofing: Offers the aesthetic of clay or slate tiles with the strength of aluminum. 4. Aluminum Panel Roofing: Consists of large panels that cover a broad area quickly and efficiently. 5. Aluminum Shake Roofing: Provides a rustic look similar to wooden shakes but with the longevity of aluminum. Each system has its own advantages and is chosen based on factors like design, cost, and environmental conditions.</p>

- Q: This question asks for a list of various fasteners that can be used to connect aluminum profiles to building structures.

- <p>There are several types of fasteners used to attach aluminum profiles to building structures, including: 1. Bolts and Nuts: Commonly used for strong and secure connections. 2. Rivets: Provide a permanent connection by deforming the rivet when installed. 3. Self-tapping Screws: Can be used to create a thread in the aluminum profile without pre-tapping. 4. Adhesives: Used for bonding profiles together, often in conjunction with mechanical fasteners. 5. Welding: Although not a fastener, welding can join aluminum profiles together by melting and fusing the materials. 6. Clamps and Brackets: Used to hold profiles in place temporarily or permanently. 7. Dowels and Pins: Used for alignment and positioning of profiles. Each type of fastener has its specific applications and advantages depending on the structural requirements and design considerations.</p>

- Q: How to distinguish aluminum alloy series?

- The classification of aluminum alloy profile series has different classification results according to different classification standards.First, the use can be divided into the following categories:1. doors and windows of the construction of aluminum windows and doors (divided into two types of doors and windows and curtain wall).2. aluminum alloy shelf aluminum profiles, they are different from the shape of the cross-section. But they are produced by hot extrusion.3. aluminum industry: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with!Two, according to alloy classification:Can be divided into 1024, 2011, 6063, 6061, 6082, 7075 and other alloy grade aluminum profiles, of which the 6 series are the most common. Grades are different in various metal components ratio is not the same, except for the commonly used aluminum profile doors and windows such as the 60 series, 70 series, 80 series, 90 series, curtain wall series aluminum profile, aluminum industry has no clear distinction model, most manufacturers are in accordance with the actual processing of customer drawings.Three, according to surface treatment requirements classification:1. anodized aluminum2. electrophoresis coating aluminum material3. powder spraying aluminum material4. wood grain transfer aluminum5., light aluminum (divided into mechanical polishing and chemical polishing two), including chemical polishing costs

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: I have a product in the aluminum above the oxidation of 20 through the hole, that is so, good heat dissipation, I do not know, right, before oxidation, punching OK?

- It is better to drill before oxidation, and then oxidize after drilling, so that the appearance will not be scratched

Send your message to us

Aircraft Aluminum Extrusion Profiles - Alloy 6060 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords