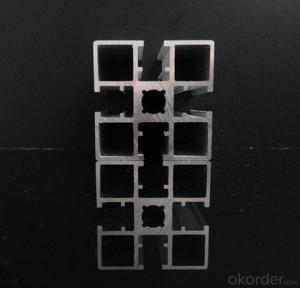

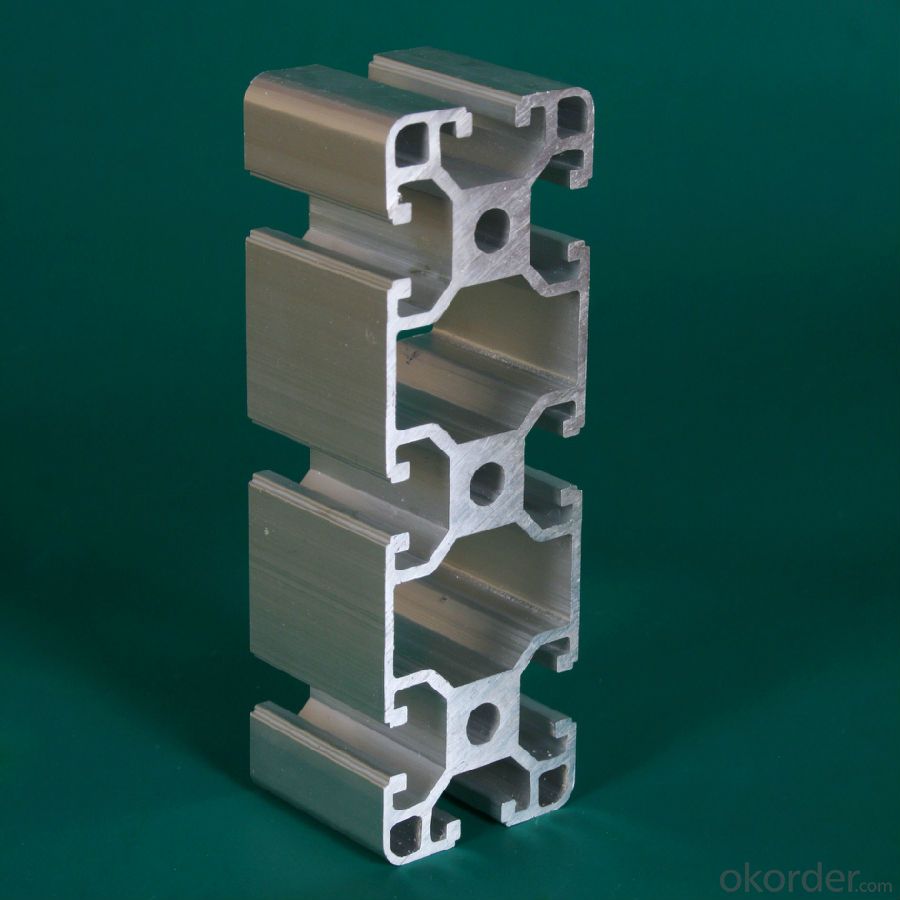

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Dongguan industrial aluminum profile manufacturers which good?

- Explain as follows: preparing goods, recruit a few operator, big online promotion can be opened. Those who are often hurt are our buyers. Miss wiring mostly do not know how to use, only know the unit price. How to use to meet customer needs; how to make the most cost-effective; in different venues that kind of connection is the best; these are they can not answer accurately. Only know the cheapest and recommended profile connection the cheapest; this connection is the lowest cost, but the cost of artificial, a connection is the weakest, aluminum convenience wouldn't be reflected, and will bring much trouble for the future reconstruction. But the wiring girl will push it one way.Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, recommended: https://cowing2010.1688 /, own also users, have very rich experience, have a good understanding and knowledge of the quality and performance of products, will be recommended for the customer needs better product price selected, convenient and practical accessories.

- Q: What are the regular colors of aluminum profiles?

- The main process is:(1) surface pretreatment: chemical or physical methods are used to clean the surface of the profile and expose the pure matrix to obtain a complete and compact artificial oxide film. The mirror or non light (Ya Guang) surface can also be obtained by mechanical means.(2) anodizing: the surface of the pre processed profiles, in a certain process conditions, the substrate surface anodic oxidation, resulting in a dense, porous, strong adsorption of AL203 film.(3) sealing: the pore space of the porous oxide film produced by anodic oxidation is closed, so that the oxidation film is anti pollution, and the corrosion resistance and wear resistance are enhanced. The film is colorless and transparent, with strong adsorption before sealing film, adsorption and deposition of metal salts in some membrane hole, can make the profile appearance character (silver) show many colors, except such as: black, bronze, golden color and stainless steel etc..

- Q: How can the aluminum profile T6 and T5 be distinguished?

- Mechanical properties are inconsistent, T5 tensile strength is 160 MPa; T6 tensile strength is 215 mpa. (normally determined by this method) do a tensile test and you'll see

- Q: Is it possible to utilize aluminum profiles in the construction of residential buildings or homes?

- <p>Yes, aluminum profiles can be used in residential buildings and houses. They are valued for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are commonly used in window frames, door frames, and as structural components due to their strength and lightweight properties. They also offer good thermal insulation and can be easily painted or finished to match the aesthetic of the building.</p>

- Q: Changhe brand aluminum can?

- Profile is not bad, but visibility is not too large, the whole is still very good, cost-effective

- Q: Can aluminum profiles be recycled indefinitely?

- Yes, aluminum profiles can be recycled indefinitely. Unlike other materials, aluminum does not degrade during the recycling process. It can be melted down and reshaped into new profiles without losing its inherent properties. This essentially means that aluminum profiles have a never-ending life cycle. Recycling aluminum requires significantly less energy and resources compared to producing new aluminum, making it an environmentally sustainable option. Moreover, the recycling process can be repeated countless times without any loss in quality, making aluminum one of the most recycled materials in the world.

- Q: Can aluminum profiles be used for shelving systems?

- Yes, aluminum profiles can be used for shelving systems. Aluminum profiles are known for their strength, durability, and versatility, making them an ideal choice for various applications including shelving systems. They can be easily customized and fabricated to fit specific dimensions and requirements, making it possible to create shelving systems of different sizes and designs. Additionally, aluminum is lightweight but sturdy, allowing for easy installation and maintenance. It is also resistant to rust and corrosion, making it suitable for both indoor and outdoor shelving systems. Overall, aluminum profiles offer a reliable and efficient solution for shelving systems.

- Q: What are the different machining options available for aluminum profiles?

- There are several machining options available for aluminum profiles, including milling, drilling, tapping, turning, and sawing. These processes can be used to create various shapes, sizes, and features on the aluminum profiles, allowing for customization and precise fabrication. Additionally, advanced techniques such as CNC machining and laser cutting can also be employed for more complex and intricate designs.

- Q: When will the aluminum mold be padded?

- The plane will die pad is a small pad on the inside of the die sleeve, and a large pad size is the size of the inner diameter of the sliding seat, there are generally several square and circular pad, some special structure material need professional pad, such as an open slot, the structure is not very stable, when die under high pressure are squashed requires a special pad.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

Send your message to us

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords