Drilling Through Aluminum Plate

Drilling Through Aluminum Plate Related Searches

Drilling Aluminum Plate Drill Aluminum Plate Drill Bit For Aluminum Plate Drilled Aluminum Plate Forming Aluminum Plate Drilling Into Stainless Steel Pre Drilled Aluminum Plate Welding Aluminum Plate Welding Aluminum Diamond Plate Tapping Aluminum Plate Drill Through Stainless Steel Aluminum Plate With Holes Welding Thick Aluminum Plate Etching On Aluminum Plate Painting Aluminum Plate Hole Saw For Aluminum Plate Aluminum Dimple Plate Polishing Aluminum Diamond Plate Painting Aluminum Diamond Plate Best Way To Cut Aluminum Plate Polishing Diamond Plate Aluminum 1 Aluminum Plate Aluminum Tool Plate An Aluminum Plate Of 25mm Thick Aluminum Plate Near Me Aluminum Metal Plate Aluminum Plate Nearby Aluminum Pressure Plate Bending Aluminum Plate Aluminum Tooling PlateDrilling Through Aluminum Plate Supplier & Manufacturer from China

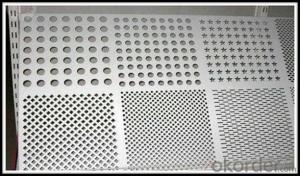

Drilling Through Aluminum Plate is a specialized product designed for efficient and precise drilling operations on aluminum materials. This product is engineered to provide optimal performance and durability, ensuring that users can achieve clean and accurate holes in aluminum plates with ease. The versatility of Drilling Through Aluminum Plate makes it an essential tool in various industries, including construction, automotive, aerospace, and manufacturing. Professionals in these fields rely on this product to maintain high-quality standards and achieve efficient production processes.Drilling Through Aluminum Plate is widely used in applications where lightweight and strong materials are required, such as in the construction of aircraft, automotive components, and architectural structures. Its ability to maintain precision and strength during drilling operations makes it a popular choice for professionals who demand high-quality results. Additionally, the product's compatibility with various drilling equipment and techniques allows for greater flexibility and adaptability in different work environments.

Okorder.com is a leading wholesale supplier of Drilling Through Aluminum Plate, offering a vast inventory of this product to cater to the needs of businesses and professionals worldwide. With a commitment to providing high-quality products and exceptional customer service, Okorder.com ensures that customers receive the best possible Drilling Through Aluminum Plate for their specific applications. By partnering with reputable manufacturers and maintaining a large inventory, Okorder.com is able to deliver this essential product to customers at competitive prices and with fast shipping options.

Hot Products