Drilling Aluminum Plate

Drilling Aluminum Plate Related Searches

Drilling Through Aluminum Plate Drill Aluminum Plate Drilled Aluminum Plate Drill Bit For Aluminum Plate Welding Aluminum Plate Pre Drilled Aluminum Plate Welding Aluminum Diamond Plate Forming Aluminum Plate Aluminum Dimple Plate Welding Thick Aluminum Plate Tapping Aluminum Plate Aluminum Mounting Plate Aluminum Pressure Plate Laser Cutting Aluminum Plate Aluminum Tooling Plate Painting Aluminum Plate Aluminum Metal Plate Bending Aluminum Plate Aluminum Cooking Plate Aluminum Grill Plate Aluminum Deck Plate Aluminum Surface Plate Aluminum Dimond Plate Aluminum Tool Plate Aluminum Profile Plate Polishing Aluminum Diamond Plate Aluminum Cover Plate Polishing Diamond Plate Aluminum Aluminum Spinning Plate Painting Aluminum Diamond PlateDrilling Aluminum Plate Supplier & Manufacturer from China

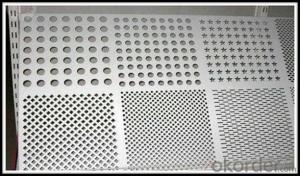

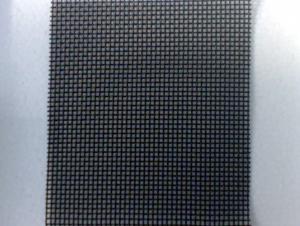

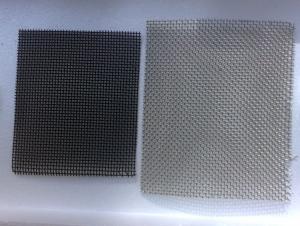

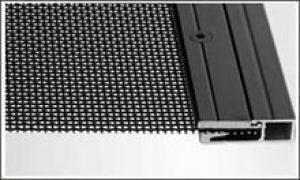

Drilling Aluminum Plate is a type of metal material that is widely used in various industries due to its high strength, lightweight, and corrosion resistance properties. This product is specifically designed for drilling applications, making it an ideal choice for creating holes in aluminum plates for various purposes. The versatility of Drilling Aluminum Plate allows it to be utilized in a range of applications, including construction, automotive, aerospace, and electronics industries. Its usage scenarios span from structural components to intricate parts requiring precise drilling and machining. Okorder.com, as a reputable wholesale supplier, offers a vast inventory of Drilling Aluminum Plate to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Drilling Aluminum Plate they provide meets the highest industry standards and is available at competitive prices.Hot Products