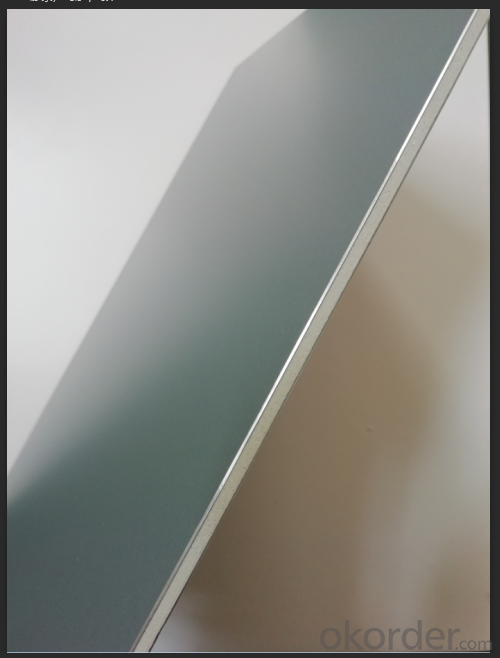

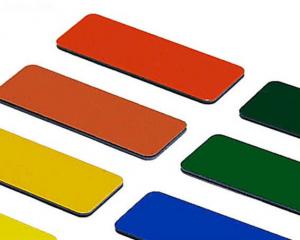

Class A2 fireproof board 、Aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The main product features:

First, our company can produce A2 fireproof board product specifications:

Available: PE/PVDF/FEVE/NANO

Thickness: 3-6mm

Width: 1220-1600mm

Aluminum skin thickness: 0.2-0.7m0

Two, product use

1, the subway station, high-speed rail station, train station, airport terminal, terminal and wall decoration;

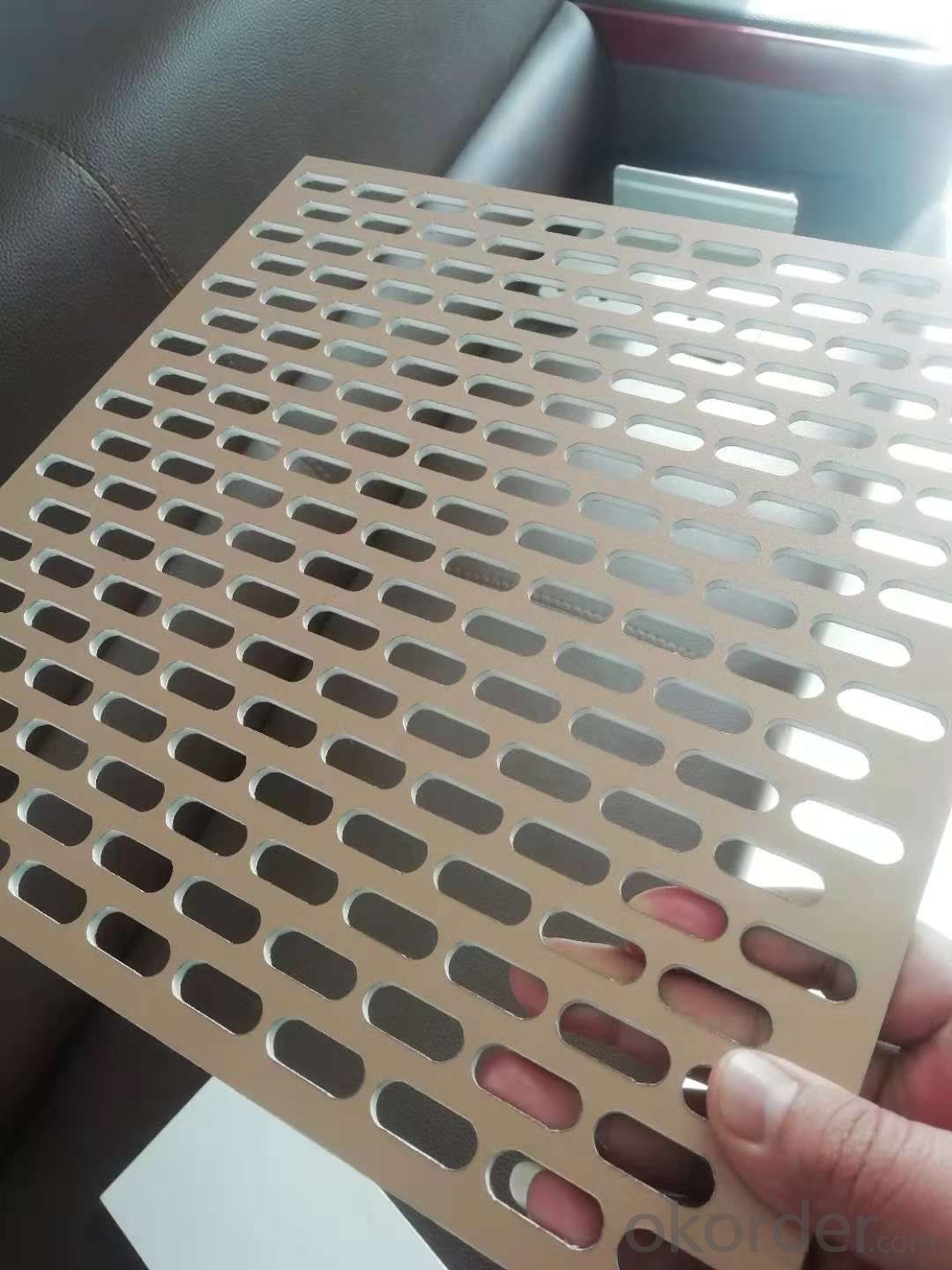

2, CBD business center, exhibition center, high-rise building building, office buildings, hotels, stadiums, senior residential building exterior decoration, billboards, shopping malls decoration panel;

3, large hospitals, medical equipment, beauty salons, health clubs, nursing homes, kindergartens and other external decoration.

Three, product performance and advantages:

1, excellent fire high cost

A grade fireproof performance fireproof composite board with high grade, is fireproof board, the flame sustained combustion time is zero.

1200 C no flames reached the high level a fireproof,

With the high quality production of keel partition system resistance limit reached more than 4 hours, the fire burning process can absorb a lot of heat, delay and elevated ambient temperature.

A fireproof composite board, stable and reliable quality, compared with other aluminum-plastic plate, light energy, moderate price.

Product surface can be coated with nano coating, more resistance, anti pollution, can achieve the self clean effect of natural rainwater utilization, from the modern high-rise large buildings in maintenance and maintenance costs.

2, high strength superior weatherability

A fireproof composite board has a strong weatherability and anti UV properties, acid resistance, alkali resistance, can withstand the harsh environment test, thermal expansion and contraction of small changes, the shrinkage rate is less than 0.2%, wet expansion rate less than 0.4%, can withstand the temperature of -80 DEG C -40. The coating product uses the international brand, color and gloss, and can provide up to 20 years of warranty does not fade.

A fireproof composite board has the advantages of light weight, compact structure, good stability, with wood like toughness. In compression, tensile, flexural and impact resistance, toughness and economic performance.

3, heat insulation and energy saving environmental protection and health

The characteristics of a fireproof composite plate inorganic core layer has pores is uniform and compact, the thermal conductivity of 0.216w/cm.k, ratio of lime sand brick cut (1.1w/cm.k) more insulation, saving energy consumption, make the bedroom maintain a comfortable environment and fresh air.

A fireproof composite board does not contain asbestos, formaldehyde, benzene and harmful radioactive elements, in case of fire, smoke-free, non-toxic, no smell. The production of materials for natural mineral and plant fiber, natural curing, the production process of low energy consumption, no row of dirt, energy saving and environmental protection, the use of surface off powder, its unique natural pore structure, can adjust the indoor temperature, and makes the room more comfortable office.

4, sound and light seismic heterogeneity

A sound insulation fireproof composite board to ensure the living environment quiet and elegant, the thickness of 3mm sheet insulation capacity of 29dB, double 4mm thick sheet partition system air sound is less than 42db, its unique pore structure is uniform and dense structure plate other incomparable

The surface density of a fireproof composite board for 0.8-12g/cm -, reduce the building load, can effectively reduce the earthquake resistant structure, foundation and structure of the main cost; while making building walls to reduce the weight of more than 60%, while increasing the use of the area 5-8%.

- Q: Aluminum-plastic plate of the thick aluminum thickness can be thicker?

- The aluminum thickness of the aluminum-plastic plate can be made into a different thickness depending on the actual use of the user. In general, the aluminum plate thickness of the thickest aluminum can do 50 silk, which is in the whole board thickness of not less than 4mm in the case, if the whole board thickness is too thin, then it can not do so thick The aluminum is thick. Buy good quality aluminum-plastic board, recommended Astra aluminum plate.

- Q: Who prawn know that there is no aluminum plate factory in Shenyang it? What is the best brand and contact phone, thank you first, huh, huh

- As of today, did not hear Shenyang aluminum plate manufacturers

- Q: Aluminum plate. Aluminum plate. PVC plate plastic plate prices

- PVC board 10-16 yuan

- Q: Engraving engraving engraving engraving engraving engraving engraving engraving engraving engraving

- The feeling is that you use the tool wrong. Usually with a knife to cut aluminum-plastic plate only.

- Q: Standard for aluminum-plastic plates

- And GB / T22412-2008 "ordinary decorative aluminum-plastic composite panels" for the inner wall panels and advertising boards, 4MM the following plates apply.

- Q: Analysis of why the surface of aluminum-plastic plate deformation, from the drums

- Casually in which city in the circle, are not difficult to find some aluminum-plastic plate surface deformation, from the drums of those big unpleasant works. Small facade renovation works on this phenomenon, large high-rise buildings also have this phenomenon. In the construction, the emergence of such a quality problem, we have considered the quality of the plate itself; later, after we focus on the analysis found that the main problem lies in the paste sheet of aluminum-plastic plate, followed by aluminum The quality of the board itself. Dealers often provide us with aluminum-plastic plate construction process, the recommended use of grass-roots materials are mainly high-density board, woodworking board, etc. In fact, such materials used in the outdoor, its life is Very fragile, after the wind, sun, rain, will inevitably produce deformation. Since the grass-roots materials are deformed, then as the surface of the aluminum-plastic plate that is not deformed? Can be seen, the ideal outdoor base material should be After the rust treatment of angle steel, square steel pipe to form a skeleton is better.If the conditions permit, then use aluminum as a skeleton is more ideal. This type of metal material produced skeleton, the cost is not higher than the wood keel, high density Many, can really guarantee the quality of the project.

- Q: Will the aluminum curtain wall refers to the metal aluminum curtain wall, or aluminum veneer aluminum-plastic curtain wall?

- In general, aluminum curtain wall refers to the aluminum veneer curtain wall, but now also refers to the aluminum honeycomb curtain wall, you can according to your needs to find suppliers, if the need for aluminum veneer, aluminum honeycomb products can find Reynold Aluminum veneer manufacturers, their product quality is very good oh

- Q: Why do you stay 0.3mm plastic when processing aluminum-plastic composite board?

- Protect the aluminum skin is not directly exposed to the air, but also in the folding time is not easy to break

- Q: The outer wall is to play on the west is good paint, or aluminum-plastic plate is good?

- More by that

- Q: What are the specifications of aluminum-plastic plates?

- Specifications Size: The common dimensions of the curtain wall are as follows:

Send your message to us

Class A2 fireproof board 、Aluminum composite panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 40000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords