High Quality Aluminum Profiles Sliding Screen Door Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

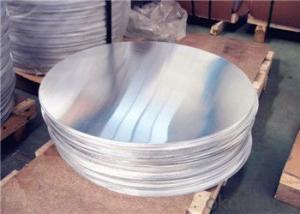

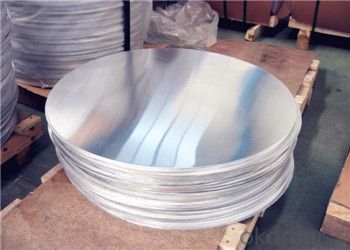

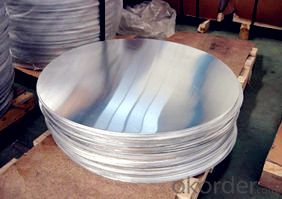

Aluminum Wafer

Aluminum Wafer Description

Aluminum wafers are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances,heat preservation,machinery manufacturing,automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Aluminum Wafer Production Methods

Punch processing

1. Rough material cut (cut into a square)

2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Wafer Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Aluminum Wafer Packaging

Technical Features of Aluminum Wafers Production Line

1. NC automatic, the production line from the coil from the volume, until the whole roll material to complete the middle of the material does not require manual contact with any material, do not need any adjustment, fundamentally put an end to the ordinary punch punch production safety risks and Product quality hidden.

2. The line can use the coil directly to the wafer production, do not need to roll the material slitting and cross-cutting treatment, reducing the production process, reducing the cost of production and reduce the damage to the surface of the material may be produced Wafer to ensure that no oil, no scratches.

3. The line full use of the width of the coil, the use of high-precision servo motor drive system control, so that the wafer spacing and wafer to the material edge of the distance to a minimum, fundamentally reduce the amount of waste, raw material utilization rate of 80% the above.

4. The production rate can reach 40-55 per minute, to improve the production efficiency.

5.Due to the use of modular mold design, when the conversion of wafer production specifications, the conversion time can be reduced to 15 minutes or less. The diameter of the wafer that can be produced ranges from 85 mm to 750 mm.

6. Advanced open system, six heavy leveling machine, high rigidity of the mechanical presses, automatic palletizing system, to ensure that the wafer products of high quality.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: Are aluminum profiles suitable for bathroom fittings and accessories?

- Yes, aluminum profiles are suitable for bathroom fittings and accessories. Aluminum is a versatile material that is corrosion-resistant, lightweight, and durable, making it an ideal choice for bathroom fittings. Aluminum profiles can be used for various bathroom accessories such as towel racks, shower curtain rods, soap dispensers, and shelves. Additionally, aluminum can be easily shaped and molded into different designs and finishes, allowing for customization and aesthetic appeal. Its resistance to moisture and humidity also makes it a suitable choice for bathroom environments. Overall, aluminum profiles provide a practical and stylish solution for bathroom fittings and accessories.

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: What does "T" in the aluminum profile 6063-T5 mean?

- China's current general is the United States Aluminum Association "Aluminium Association" numberT5By cooling the high temperature molding process, and then the artificial aging state. Applied by cooling high temperature molding process, not through the cold processing (for straightening and leveling, but does not affect the mechanical properties of the limit), to artificial aging products.

- Q: Are aluminum profiles suitable for use in automotive engine components?

- Yes, aluminum profiles are suitable for use in automotive engine components. Aluminum is widely used in the automotive industry due to its lightweight nature, high strength-to-weight ratio, and excellent heat dissipation properties. These characteristics make it an ideal material for engine components that need to withstand high temperatures and provide efficient performance. Aluminum profiles are commonly used in various engine components such as cylinder heads, engine blocks, intake manifolds, and pistons. The lightweight nature of aluminum helps reduce the overall weight of the engine, resulting in improved fuel efficiency and reduced emissions. Additionally, the high strength of aluminum allows for the design of complex shapes and intricate details, enhancing the overall performance and efficiency of the engine. Furthermore, aluminum has excellent thermal conductivity, which allows for efficient heat transfer. This is particularly important in engine components where heat dissipation is critical, such as cylinder heads and pistons. Aluminum profiles can effectively dissipate heat, preventing overheating and improving the longevity and reliability of the engine. Moreover, aluminum is a corrosion-resistant material, which is crucial for automotive engine components that are exposed to various environmental conditions, including moisture and chemicals. The corrosion resistance of aluminum ensures the longevity and durability of the engine components, reducing maintenance and replacement costs. In summary, aluminum profiles are highly suitable for use in automotive engine components. Their lightweight nature, high strength, excellent heat dissipation properties, and corrosion resistance make them an ideal choice for enhancing the performance, efficiency, and durability of automotive engines.

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- Is it ready to estimate?. Custom mold. If the simple section of the mold is about two thousand yuan (our company has many of these profiles on the outside to buy), the mold fee is in a certain amount can be returned.

- Q: Do aluminum profiles require any special maintenance?

- Yes, aluminum profiles require minimal maintenance. They are highly resistant to corrosion and rust, so regular cleaning with mild soap and water is usually sufficient. It is important to avoid using abrasive cleaners or tools that may scratch the surface. Additionally, lubricating moving parts with a silicone-based lubricant can help maintain their smooth operation. Overall, aluminum profiles are relatively low maintenance compared to other materials.

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Here are a few guidelines to follow: 1. Regular cleaning: Aluminum profiles should be regularly cleaned to maintain their appearance and prevent corrosion. Use a mild soap or detergent mixed with water to clean the surface. Avoid using abrasive cleaners or steel wool as they can scratch the aluminum. 2. Avoid harsh chemicals: Harsh chemicals can damage the protective coating on the aluminum profiles. Avoid using strong acids, alkaline cleaners, or solvents for cleaning purposes. 3. Rinse thoroughly: After cleaning, make sure to rinse the aluminum profiles thoroughly with clean water. This will remove any residue from the cleaning solution and prevent streaking. 4. Dry thoroughly: After rinsing, dry the aluminum profiles completely using a soft cloth or towel. Moisture left on the surface can lead to corrosion, so it's important to ensure the profiles are completely dry. 5. Lubrication: If the aluminum profiles have moving parts or hinges, it's recommended to lubricate them regularly to ensure smooth operation. Use a lubricant specifically designed for aluminum to avoid any adverse effects. 6. Protective coatings: Some aluminum profiles come with protective coatings, such as anodized or powder-coated finishes. These coatings provide an extra layer of protection against corrosion and should be maintained as per the manufacturer's instructions. 7. Avoid abrasive cleaning tools: When cleaning aluminum profiles, avoid using abrasive cleaning tools such as brushes or scouring pads. These can scratch the surface and damage the protective coating. It's important to note that specific cleaning and maintenance instructions may vary depending on the type and finish of the aluminum profiles. Therefore, it's always advisable to refer to the manufacturer's guidelines for the best cleaning and maintenance practices for your specific aluminum profiles.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: This question asks for methods to prevent aluminum profiles from rusting during the transportation process.

- <p>To prevent rusting of aluminum profiles during transportation, ensure proper packaging with moisture-resistant materials. Use protective films or covers to shield the profiles from direct contact with moisture and humidity. Maintain a controlled environment in the transport vehicle, avoiding high humidity and condensation. Regularly inspect the profiles for any signs of moisture or damage and address them promptly. Additionally, consider using rust inhibitors or anti-corrosion coatings on the aluminum profiles before packaging. Always handle the profiles with care to avoid scratches or damage that could lead to rusting.</p>

- Q: How do you select the appropriate aluminum profile for a specific application?

- Selecting the appropriate aluminum profile for a specific application involves considering several key factors. Firstly, it is important to understand the requirements and specifications of the application. This includes considering factors such as the load-bearing capacity, structural integrity, and overall functionality needed for the application. Next, it is crucial to evaluate the characteristics of the available aluminum profiles. This involves considering factors such as the alloy composition, strength, hardness, and corrosion resistance. Each application may require specific properties to ensure optimal performance and durability. Additionally, it is important to assess the dimensions and shape of the aluminum profile. This involves considering factors such as the length, width, and thickness required for the application. The shape of the profile, whether it is square, rectangular, or custom-designed, should also be taken into account. Another aspect to consider is the surface finish of the aluminum profile. Depending on the specific application, the surface may need to be smooth, textured, or treated to enhance its appearance or provide additional protection against wear, abrasion, or corrosion. Furthermore, it is essential to consider the availability and cost of the chosen aluminum profile. Evaluating the availability of the required profiles from different suppliers and assessing their cost-effectiveness is crucial to ensure that the chosen profile aligns with the budget and project timeline. Lastly, seeking expert advice and consulting with professionals who have experience in aluminum profiles for specific applications can be beneficial. They can provide valuable insights and recommendations based on their knowledge and expertise. In conclusion, selecting the appropriate aluminum profile for a specific application involves considering factors such as the application's requirements, the characteristics of the aluminum profile, dimensions and shape, surface finish, availability, cost, and seeking expert advice. By carefully considering these factors, one can choose the most suitable aluminum profile that will meet the requirements of the application effectively.

Send your message to us

High Quality Aluminum Profiles Sliding Screen Door Wafer with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords