High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

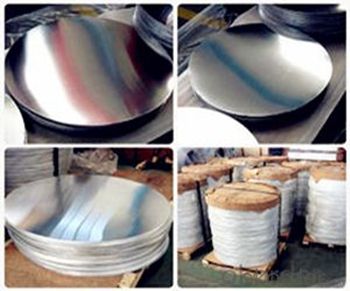

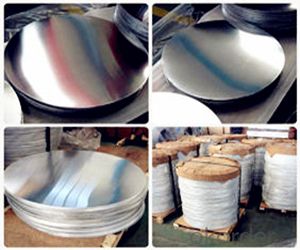

Aluminum Circles for Kitchenware

Aluminum Circles Specification

Alloy: 1050, 1060, 1070, 3003, 5052, 3105, 6061

thickness:0.15-8mm

diameter: 20-1200mm

Aluminum Circles Application

aluminum circle Tolerance: thickness tolerance +/-3%, diameter tolerance +/-1%mm

Deep drawing cookware, spinning cookware, road sign, Building Material,Insulation, and so on.

Aluminum Circles Picture

Aluminum Circles Features

1.Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use.

2.Chemical Composite and Mechanical Property could meet the requirements of GB/T, ASTM, ENAW, JIS Standard.

Aluminum Circles Packing

1.Plastic cloth with drying agent inside;

2.Pearl Wool ;

3.Wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film.

Introduction of our company

Our company is one of the largest aluminum cookware producer in China, and we have produced aluminium circles over 20years, our aluminum circles could be good quality for cookware deep drawing and spinning dawing usage.

Also we are the professional Aluminium Strip manufacturer and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,Aluminum Strip, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: Are aluminum profiles resistant to pests or insects?

- Generally, pests or insects are not a problem for aluminum profiles. This is because aluminum is a non-porous material that does not offer a suitable environment for pests or insects to nest or feed on. Unlike wood, which can be prone to termite infestations, aluminum profiles are not susceptible to insect damage. The smooth surface of aluminum makes it difficult for insects to crawl or burrow into, effectively preventing them from entering the structure. Moreover, aluminum profiles are frequently used for windows, doors, and other entry points, and their tight seals further restrict the entry of pests or insects into a building. In summary, aluminum profiles offer a long-lasting and pest-resistant solution for various applications.

- Q: Are aluminum profiles suitable for constructing railings or staircases?

- <p>Yes, aluminum profiles are commonly used for railings and staircases due to their strength, durability, and low maintenance requirements. They offer a modern aesthetic and are resistant to corrosion, making them ideal for both indoor and outdoor applications. Aluminum profiles can be easily customized to fit various designs and can be powder-coated or anodized for enhanced visual appeal and protection against the elements.</p>

- Q: What are the reasons for the slow down of aluminum extrusion press?

- Take a look at the push bar when the proportion of current is the largest, if not, can be adjusted to try.See if the two shift is too small.

- Q: Can aluminum profiles be bent or shaped?

- Yes, aluminum profiles can be bent or shaped. Aluminum is a highly malleable metal, allowing it to be easily formed into various shapes and angles through processes such as bending, rolling, or extrusion. This flexibility makes aluminum profiles a popular choice in many industries for creating customized designs and structures.

- Q: Can aluminum profiles be used in the production of laboratory equipment?

- Laboratory equipment manufacturing can utilize aluminum profiles effectively. Aluminum, being a versatile material, finds application in multiple industries, including the production of laboratory equipment. Aluminum profiles provide numerous benefits in this regard. To begin with, aluminum possesses a combination of lightweight and strength, making it an ideal choice for constructing portable or frequently movable equipment within laboratories. Its lightweight nature reduces the strain on laboratory personnel while handling and transporting the equipment. Moreover, aluminum profiles offer easy shaping and molding capabilities, enabling the customization of laboratory equipment to meet specific requirements. This design flexibility allows for the creation of equipment with complex shapes and structures, ensuring optimal functionality and efficiency. In addition, aluminum exhibits excellent corrosion resistance, a crucial property in laboratory settings where exposure to chemicals and liquids is common. This corrosion resistance extends the lifespan of the equipment and maintains its good condition even after prolonged use. Furthermore, aluminum profiles can be anodized or coated to provide additional protection against wear, scratches, and other forms of damage. This enhances the durability and facilitates easier cleaning, ensuring the maintenance of required hygiene standards in laboratories. Lastly, aluminum possesses high conductivity, making it suitable for applications that require heat transfer or electrical conductivity. This property proves advantageous for laboratory equipment, such as heating plates, heat sinks, or electrical circuit components. In conclusion, aluminum profiles are indeed suitable for the production of laboratory equipment. Their lightweight, malleable, corrosion-resistant, and conductive properties make them an excellent choice for manufacturing various types of laboratory equipment, guaranteeing durability, functionality, and ease of use.

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Of course, you only choose the quality of aluminum, as far as possible to choose the hardness of high bar, 5052, 5056, 6082, 7075 and so on are high strengthAluminium alloy。Our common 6063-T5 material, the door and window material is the material.

- Q: What are aluminum profiles used for?

- Aluminum profiles are commonly used in construction, manufacturing, and industrial applications. They are used for framing structures, such as doors, windows, and curtain walls, providing strength and durability while maintaining a lightweight design. Additionally, aluminum profiles are used in the production of machinery, electrical enclosures, automotive parts, and various consumer products, due to their corrosion resistance, heat conductivity, and versatility in shaping.

- Q: How do aluminum profiles perform in terms of sound transmission loss?

- Aluminum profiles generally have poor sound transmission loss properties due to their low mass and stiffness. They are not effective in blocking or reducing sound transmission compared to other materials specifically designed for acoustic insulation purposes.

- Q: Where is the aluminum profile market in Nanjing? Specific address, bus route

- Aluminum does not have the corresponding market basically, basically in Nanjing to do a relatively large Nanjing Meida aluminum, Nanjing Heng aluminium, yum Nanjing aluminum, Nanjing to build up the aluminum industry, basically is the nature of the company, you can go directly to their website to search their own needs aluminum.

- Q: How to use aluminum profile on the side of roller conveyor?

- Aluminum profile inside 1 cm thick lining board, our unit of assembly line is like that

Send your message to us

High Quality Aluminum H Extrusion Profiles for Kitchenware

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords