High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

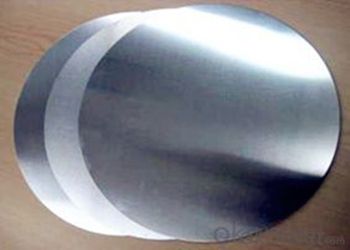

Aluminum Circles

Product introduction

Aluminum Circles are widely used in electronics, cosmetic, medicine, culture and education and auto parts. Electrical appliances, heat preservation, machinery manufacturing, automotive, aerospace,military, mold,construction,printing and other industries. Such as kitchen utensils such as non-stick pan,pressure cookers and other hardware supplies such as shades,water heaters shell,is the largest amount of aluminum alloy strip deep processing of one of the products.

Production methods

Punch processing

1. rough material cut (cut into a square) 2. Blank (punching into the Aluminum discs you want)

If it is a roll material, it is necessary to open the material.

Aluminum Circles Picture

Alloy state

Main series: 1 series, 3 series, 5 series, 6 series, 8 series is in the majority.

State : O, H ;

Introduction of our company

Our company is a professional Aluminium Coil Suppliers and Aluminum Circles manufacturers,mainly supply Aluminium Coil,Aluminum Circles,Aluminium discs,Aluminum Sheet,1100 Aluminum Sheet,1050 Aluminum Sheet,1060 Aluminum Sheet, Household Aluminum Foil,Aluminum Foil for Pharmaceutical Packaging,Aluminum Foil Tape,Aluminum Foil for Air Conditioner,Aluminum Foil for Container ,Aluminum Circles for Kitchenware,Aluminum Disc for Cookware,Aluminium Circle Sheet etc. series of aluminum products, sincerely welcome everyone to visit.

- Q: Can aluminum profiles be used in agricultural greenhouse manufacturing?

- Yes, aluminum profiles can be used in agricultural greenhouse manufacturing. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for use in greenhouse structures. Aluminum profiles can be used to create the framework of the greenhouse, providing structural support and stability. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in greenhouse design. The use of aluminum profiles in agricultural greenhouse manufacturing helps to ensure a long-lasting and efficient structure for growing plants.

- Q: What are the different alloys available for aluminum profiles?

- There are several different alloys available for aluminum profiles, including 6061, 6063, and 6082. These alloys vary in their composition and properties, allowing for different levels of strength, corrosion resistance, and machinability. Each alloy has its own unique characteristics, making them suitable for various applications and industries.

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- Is it ready to estimate?. Custom mold. If the simple section of the mold is about two thousand yuan (our company has many of these profiles on the outside to buy), the mold fee is in a certain amount can be returned.

- Q: Can aluminum profiles be used in construction?

- Indeed, construction can benefit from the utilization of aluminum profiles. This material boasts properties such as being lightweight, durable, and resistant to corrosion, thereby rendering it suitable for a multitude of construction purposes. Common applications encompass the construction of windows, doors, curtain walls, and roofing systems. Notably, the versatility of aluminum profiles permits the realization of intricate designs and structures. Furthermore, it is crucial to acknowledge that aluminum is an eco-conscious option for construction endeavors due to its high recyclability.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or walls within a building.

- <p>Yes, aluminum profiles can be used for interior partitions or walls. They are lightweight, durable, and offer excellent resistance to corrosion. Aluminum profiles are easy to install and can be used in various configurations, making them suitable for both residential and commercial spaces. They also provide good thermal insulation and can be combined with other materials like glass or fabric for aesthetic and functional purposes.</p>

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: How do aluminum profiles compare to other types of materials?

- Aluminum profiles have several advantages over other types of materials. Firstly, aluminum is lightweight, making it easier to handle and transport. It is also highly resistant to corrosion, making it ideal for outdoor or high-moisture environments. Additionally, aluminum profiles offer excellent strength-to-weight ratio, providing structural stability without unnecessary weight. Moreover, aluminum is a highly versatile material that can be easily shaped and customized to meet specific design requirements. Lastly, aluminum is sustainable and recyclable, making it an environmentally friendly choice. Overall, aluminum profiles offer numerous benefits in terms of durability, versatility, and sustainability compared to other materials.

- Q: Can aluminum profiles be used for creating display systems?

- Yes, aluminum profiles can be used for creating display systems. Aluminum is a versatile and lightweight material that is widely used in various industries, including the display and signage industry. Aluminum profiles offer several advantages for creating display systems. Firstly, aluminum is highly durable and corrosion-resistant, making it suitable for both indoor and outdoor display applications. It can withstand various environmental conditions, ensuring the longevity of the display system. Secondly, aluminum profiles are easily customizable. They can be extruded into various shapes and sizes, allowing for flexibility in design. This makes it possible to create unique and eye-catching display systems that meet specific requirements. Additionally, aluminum profiles are easy to assemble and disassemble, which is beneficial for display systems that require frequent changes or transportability. They often come with a simple slot and groove system or other connecting mechanisms, making installation and maintenance hassle-free. Moreover, aluminum profiles can be anodized or powder-coated to provide a decorative or protective finish. This allows for customization in terms of color and texture, enhancing the aesthetics of the display system. Lastly, aluminum profiles provide structural stability while remaining lightweight. This makes them suitable for large-scale displays or installations where weight is a concern. In summary, aluminum profiles are an excellent choice for creating display systems due to their durability, customizability, ease of assembly, and aesthetic appeal.

- Q: Are aluminum profiles suitable for balcony railings?

- Yes, aluminum profiles are suitable for balcony railings. Aluminum is a popular material choice for balcony railings due to its durability, strength, and low maintenance requirements. It is resistant to rust and corrosion, making it highly suitable for outdoor use. Additionally, aluminum profiles can be easily customized and shaped to fit any design preference or architectural style. They are lightweight, yet sturdy enough to provide the necessary support and safety for balcony railings. Aluminum railings are also available in a variety of finishes and colors, allowing for endless design possibilities. Overall, aluminum profiles are a reliable and stylish option for balcony railings.

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

Send your message to us

High Quality Aluminum Extrusion Profiles C Channel with a Good Price

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords