Plastic extruder/PVC pipe extrusion machine/pipe extrusion line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction

Extruder/Screw And Barrel for Extruder/Plastic Extrusion

Screw Diameter 55 to 65mm

30 to 100 KG/HR

AC20 to 40HP/11.5 to 15KW

Characteristic

Pipe range | 20-63mm single | 20-63mm dual | 75-160mm | 110-315mm | 315-630mm |

Extruder | CMAX51/105 | CMAX65/132 | CMAX80/156 | CMAX80/156 | CMAX92/188 |

Extruder power | 18.5kw | 37kw | 37kw | 55kw | 110kw |

Extrusion capacity | 120kg/h | 250kg/h | 250kg/h | 360kg/h | 800kg/h |

Max. Production speed | 12m/min | 10m/min | 6 m/min | 3 m/min | 1.2m/min |

Process flow

PVC powder + additive --- mixing---feeder---twin screw extruder---mould and calibrator---vacuum forming machine---haul-off machine---cutting machine---discharge rack(or belling machine)

Application

PVC pipe is mainly used in the agricultural water supply and drainage, water supply and drainage construction, cable supporting, thickness of pvc plastic pipe, The lines have conical twin-screw extruder, vacuum calibration tank, haul-off machine, cutting machine, stacker or belling machine and so on. Haul-off machine have two caterpillar, three caterpillar, and four caterpillar, six caterpillar, the cutter use knife-raised cutter or planetary cutter which support chamferring function. And the stacker take into account length, production line is reliable performance, and high quality, we have exported to Egypt, Brazil, Syria, Uzbekistan etc.

Features

1) Main machine uses PVC twin screw, and notch feeder with powerful water

cover cooler, which has greatly improved transmitting capability and ensured

extruding.

2) Adopting double pipe extrusion method, it can greatly increase productivity.

3) Adopting high efficiency double-cavity vacuum calibrating technology and spray-paint

cooler gullet, which improve the finished product passing rate, and meet

the requirements of high speed manufacturing. Vacuum calibrating platform and cooler

gullet are all made of stainless steel

4) Adopting multi-caterpillar haul-off, through the central motor to run all the caterpillar

to reach same height, and ensure roundness of pipes

5) Adopting fully automatic control system with high precision, reliable operation,

easy and convenient handling

6) Suitable pipe diameter: 20 - 630mm

System configuration:

(a) Feeding machine

(b) Conical twin-screw extruder

(c) Mould

(d) Vacuum calibrating tank

(e) Hauling off machine

(f) Printing machine

(g) Pipe cutting machine

(h) Pipe pile-up frame

(i) Auxiliary machine such as mixer, water chiller, belling machine and crushing machine.

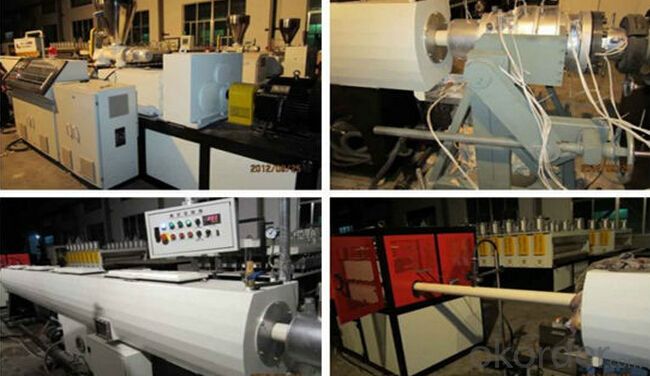

Product show

Our machine types:

1. Co-Rotating Parallel Twin Screw Pelletizing Extruders

2. Single Screw Pelletizing Extruders

3. Die Face Cut (Air Cooling) Pelletizing Extruders

4. Double Stage / Double Degassing Recycling Extruders

5. Crushers, Mixers, Storage Tanks, Vibrators, Granulators, Blowers

6. Extruder spare parts

FAQ

PVC sheet extrusion

*Q: What’s the price of this machine please?

*A: Dear customer, for each kind of our machines, we have lots of models.

Generally speaking, we design the production lines according to

different requirements of different machines from different customers.

Therefore, the prices are different. So please kindly inform us your requirements.

For example, the raw material, the output product size, capacity and etc.

The more detailed, the better. Our Engineers will design a suitable production line for you.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q: What is an extruder?

- Usually called extruder, it is a plastic extrusion machine.

- Q: What are the common extrusion molding products?

- A plastic pipe, including water supply and drainage pipe, casing and other electrical B plastic doors and windows just C a variety of wire, cable, cable break, also includes a data line, wire headset D PVC ceiling e for plastic guardrail protection f roadside flowers and some decorative strips, temporary thought so much, there are a lot of specific products and you look at the things around you can think of

- Q: What is the adjustment method of China's extrusion machine die?

- (4) lamp alignment: suitable for polythene plastic wires and cables. Use light to illuminate the insulating layer and sheath, observe the upper, lower, left and right sides of the thickness, adjust the screw to the die until it is even, then screw the screws.

- Q: Extrusion blow molding machine, storage or continuous type good?

- This is not good or bad, depends on what your product is If the product cycle large volume high capacity is bound to produce a product with storage because of your long,

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- It must be injection, you see that hole, that button, can not squeeze out.

Send your message to us

Plastic extruder/PVC pipe extrusion machine/pipe extrusion line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords