Plastic Sheet Extrusion Machine For PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line:

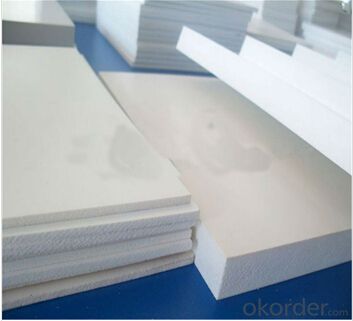

PVC/WPC Free Foamed Sheet Production Line

Professional manufacture with more than 10 years experience.

High output , low consumption

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line

Features:

The plastic plate and sheet extrusion line is specially designed for the extrusion of single layer or multi-layer plate and sheef of PC or PMMA. It is also suitable for the sheet extrusion of PE , PP, PS, ABS and other materials.

The international famous components, combined with decades of year’s experience in the plastic machinery industry, make the whole production line more perfect, reliable and steady.

Product Technical Parameters:

model | CMAX120/21 | CAMX 80/156-1220 |

products width(mm) | 1400 | 1220 |

| products thickness | 0.3-1.5 | 0.5-3 |

extruder specification | CMAX120/21 | CMAX80/156 |

Main motor power(KW) | 90 | 75 |

| Designed extrusion output(KG/H) | 350 | 300 |

Our service:

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- I've also encountered (missing a pulse alarm), and finally checked out is a SCR triggered, impassability, you can try

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation, PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: Why is the connection between the extruder and the switchboard?. The upper and lower three terminals are short circuited

- The action should be to require three simultaneous electricalOr a two way backup

- Q: What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump is opened, the air in the extruded product will be removed and the product material will be more closely packed. If the vacuum pump does not open, it may cause bubbles in the extruded product.

- Q: What is the adjustment method of China's extrusion machine die?

- (4) lamp alignment: suitable for polythene plastic wires and cables. Use light to illuminate the insulating layer and sheath, observe the upper, lower, left and right sides of the thickness, adjust the screw to the die until it is even, then screw the screws.

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Why? What is the raw material of plastics? What is the process flow of the process?.

- 1. injection molding2., the structure is relatively complex, high appearance requirements. Extrusion does not meet requirements3. most are: ABS, ABS+PC, PP and so on4., according to color requirements granulation - drying particles - filling the mold ---- debugging injection molding machine ---- injection molding production - after the selection of finished packaging (if silk screen requirements, but also the need for silk screen)

- Q: How to adjust the 65 screw gap in the extruder?

- That's the tune.This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q: How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

Send your message to us

Plastic Sheet Extrusion Machine For PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords