Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | PP film winding and then to the wooden box |

| Delivery Detail: | 30 days after confirming the deposit |

corrugated pipe extrusion line

Application

Mini single wall high speed corrugated pipe forming machine: Can produce two diameters or three diameters

single wall corrugated pipe in the same mould blocks, which reduce the cost of the mould blocks and reduce

the time for changing the mould blocks, increase the efficiency.

Advantage: The pipe from this machine is anti-high temperature, anti-wear, and high strength, and it is

widely used in electrical conduct, car conduct pipe, protective pipe, machine area and automatic meter area.

With Jwell special design screw and advanced mould, the line is high speed, run stable and easy-control.

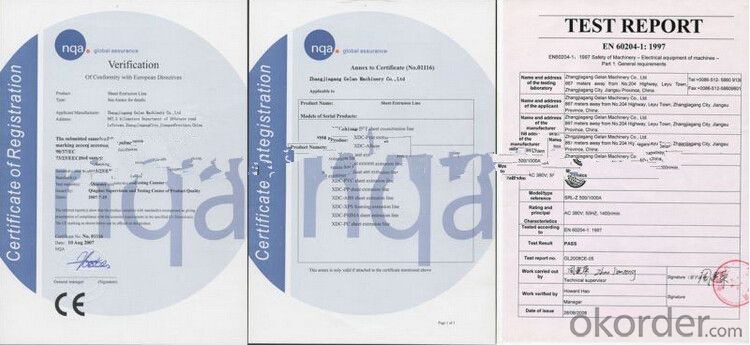

Certification:

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- PVC1.6 DYWL material with smaller good-looking it is simple of the extrusion process

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- As far as actual production is concerned, it is necessary to go beyond the regulations to produce normally

- Q: What are the two types of extrusion?

- Extrusion? The extruder. The extruder is divided into single screw extruder and twin screw extruder, and the twin screw extruder is divided into two parts: flat, double and cone.

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: Extrusion blow molding machine, storage or continuous type good?

- and material in the screw for a long time to use the storage type is also in order to meet the demand for raw materials productsIf you are doing small things, your hourly output will not consume the maximum hour.

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- See the ACS510 manual, this type of inverter used in fan pump type, 2605 control methods of determining its U/F, the default value is 2 (the square type, namely fan pump type); for constant torque load, should be set to 1 (linear). When not available, does the debugger not modify the parameter to 1? If that's the case, will the top floor say what happened?

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- What are the operating specifications for the extruder?One is the equipment instructionTwo is the boot operation specificationsThree is safety instructions and so onThe equipment manufacturer will provide the above

Send your message to us

Special Use Single Wall and Double-wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches