HDPE/PP/PVC Horizontal Type Double Wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | According to your requirements |

| Delivery Detail: | 7-21 workings days after received your prepayment |

Properties:

HDPE/PP/PVC horizontal type DWC pipe extrusion line produced by CNBM has many patents. Full automatic control, running stable, high capacity. HDPE/PP material use high efficient single screw extruder, and PVC material use conical twin screw extruder or parrallel twin screw extruder. Horizontal type corrugator adopt advanced shuttle-type structure, closed water cooling system, on-line belling. Whole line is controlled by PLC computer.

Plastic Corrugated Pipe Features:

1. High tensile strength, compressive resistance and well impact resistance;

2. Anti-uneven settling property, and can be applicable to soft clay shifting sand foundation;

3. Convenient for connection with non-breakable joint.

4. Smooth inner wall, high friction resistance, large quantity of water flowing.

5. Decay resistance, "green pipe", avoid secondary pollution.

6. Light weight, easy for carrying and transporting, convenient for construction with low comprehensive cost.

Plastic Corrugated Pipe Advantages:

1. High density, good compression resistance and good impact resistance;

2. Good resistance of asymmetrical bedding, available being buried in the mollisol and quicksand;

3. Rubber ring connection, easy but no leakage in the joint;

4. Smooth interior wall and low friction, high flow capacity;

5. Good corrosion resistance and no environment pollution;

6. Application: municipal sewage; rainwater discharge; floodwaters drainage; irrigation; ventilation for mine and buildings; industrial waste discharge.

Plastic Corrugated Pipe Applications:

1. Civil engineering

2. Agricultural irrigation

3. Conveying system for sewage plant

4. Pre buried piping under highway

5. Ventilation piping for chemical industry and mine

6. Power telecommunication cable conduit

7. Bridge construction

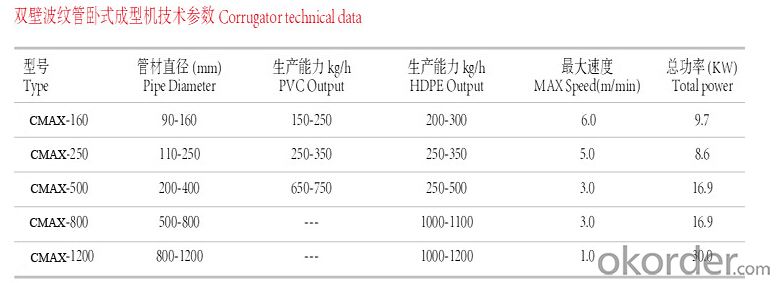

Technical parameters:

Main Products

- Q:Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

- Q:Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q:What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting. Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:Is the extruder the same as the extruder?

- A large number of continuous production, such as tube, rod, profile, also can be used for plastic modification and granulation.The scope of the application is different, but the meaning is similar, reference material, China, extruder, trading network

- Q:Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- There is a kind of broken engineering material. I wonder if you can find it

- Q:when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q:Why do screw extruders often extrude light red plastic products?

- Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q:Why single screw extruder is controlled by high school and low?

- What is controlled by high school? I can't answer the question without saying it

- Q:What impact does the extruder vacuum pump open or close on the extrusion product?

- If the vacuum pump does not open, it may cause bubbles in the extruded product.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE/PP/PVC Horizontal Type Double Wall Corrugated Pipe Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products