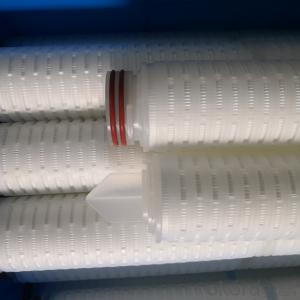

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

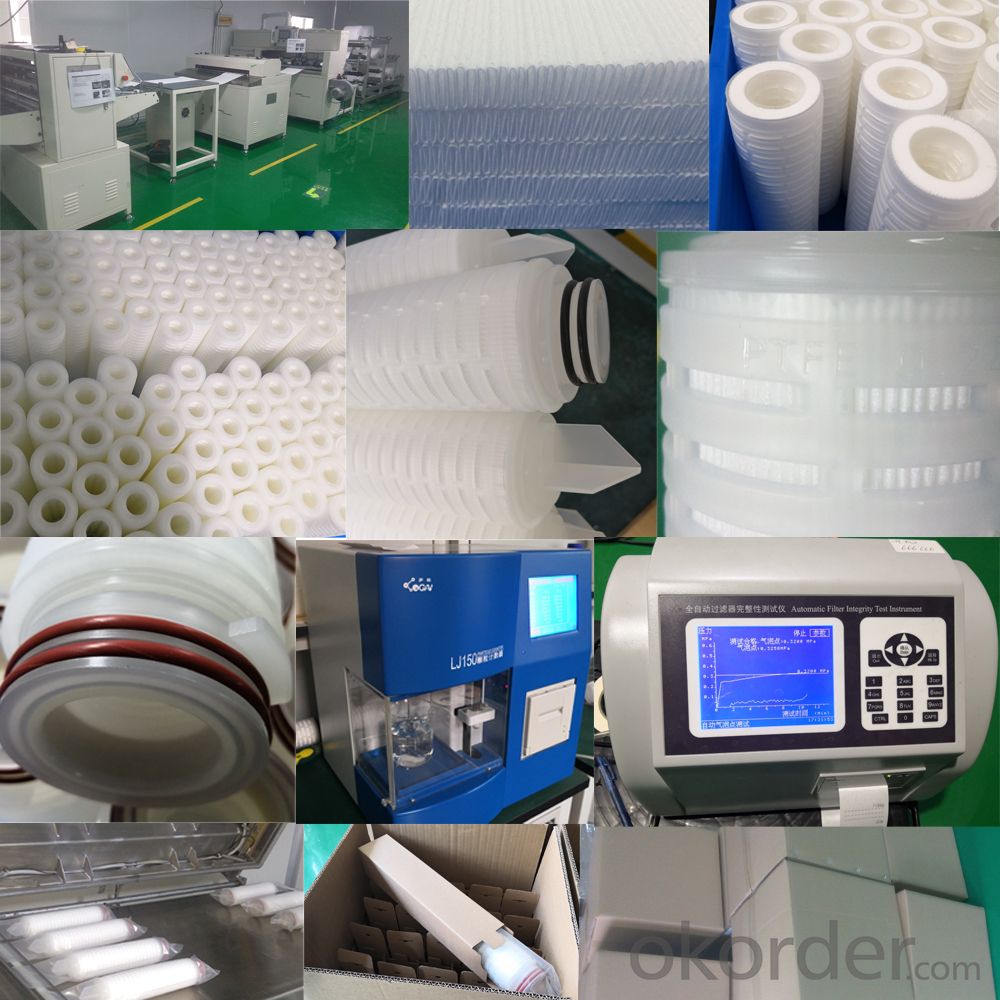

Hydrophobic Pleated PTFE membrane filter cartridges for sterile air or solvents

PTFE Filter Cartridge

PTFE Filter isa sterilizing grade air & gas filter that utilize naturally hydrophobic

material provides effective retention of microbes and particles in air/gas.

Features

l Inherently hydrophobicity.

l High flow rates at low differential pressures.

l High steam cycle lifetimes and thermal strength.

l Reliable separation of microorganisms and bacteriophage.

Materials

l Media Layer: Hydrophobic PTFE

l Support Layer: Polypropylene

l End Caps/Core/Cage: Polypropylene

l O-Rings/Gaskets: Silicon, EPDM, Viton, Teflon

l Internal Adaptor Ring: PS / Stainless Steel 304

Operating Conditions

Max. running temperature | ≤80 ℃ |

Max. Allowable Differential Pressure | ≤5Bar(20℃) |

≤2Bar(80℃) | |

Inline Steaming Sterilize | 121 ℃, 30min@max differential Pressure of 0.05MPa up to 25 times |

Food and Biological Safety

Extractables | <30mg per 10 inch |

Endotoxins | <0.25EU/mL |

Ordering Information

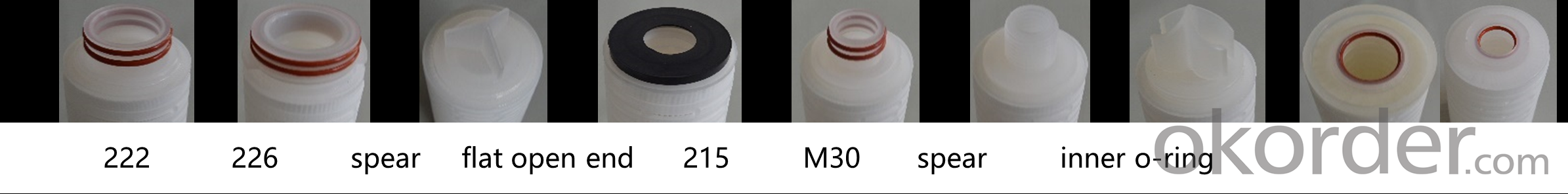

PTFE | Micro Rating | Connection | Length | Gasket |

01=0.1μm | 0=222+Flat | 10=10 inch | S=Silicon | |

02=0.22μm | 5=222+Spear | 20=20 inch | E=EPDM | |

04=0.45μm | 7=226+Spear | 30=30 inch | V=Viton | |

10=1μm | F=DOE | 40=40 inch | F=PFA |

Connection details

Process

- Q: What equipment management documents have been issued by the state, such as the regulations on the administration of equipment owned by industrial enterprises owned by the whole people under the State Council for 87 years?

- Doors and state farms must rely on technological advances, and adhere to the use of maintenance and replacement of the combination of Technology

- Q: What's the process of starting a mineral water company?

- tax registration certificate", tax bureau.

- Q: Where is the manufacturer of pure water equipment?

- pretreatment, primary reverse osmosis, dosing machine (PH control), the middle water tank, second stage reverse osmosis (positive charge of reverse osmosis membrane), pure water tank, water pump, EDI device, ultraviolet sterilizer, 0.2 or 0.5 m precision filter, water object (more than 17M Omega.CM (latest) process)

- Q: Price of water purifier in China Aviation Industry

- As a salesman who sells water purifiers for nearly 5 years, we have to say that the water purifier industry is a mess;

- Q: What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- The best one to find out, write specifications,

- Q: What are the famous water treatment plants in China?

- Thermal power, thermal power generation, factories and mines enterprises, medium and low pressure boiler power, water supply system.

- Q: Advantages and disadvantages of centrifugal filters

- This is rarely used in industry. Centrifugal filtration applied in industry, including free surface infiltration, removal of liquid from the cake layer, and removal of water from the filter cake. The centrifugal and centrifugal dewatering operations seem very similar, but they are quite different in terms of flow mechanism and

- Q: What is an industrial oil mist collector?

- oil mist collector is similar to a filter, a multi filter collector, Wuxi bodi has at least two or three layers of filter, a maximum of five layers. Each floor is made of different materials. Usually three layers

- Q: What are the categories of industrial water treatment equipment?

- precision filter, water tank self-cleaning sterilizer, ultraviolet water processor, efficient decontamination filter, hand brush filter, self cleaning brush RF filter, water filter, side stream processor, multifunctional electronic descaling device, constant pressure water supply unit, constant pressure water feeding unit,

- Q: What kind of industrial products are there in electroplating factory?

- , heat exchange equipment, freezer, air blower, anode equipment, thermal spraying

Send your message to us

Pleated PTFE membrane filter cartridges for air or solvents

- Loading Port:

- SHANGHAI

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 pc

- Supply Capability:

- 2000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches