Coalescence Filter for Natural Gas Compressor Station

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 PieceS pc

- Supply Capability:

- 10000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

coalescence filter is used to coalesce water in oil with high effeciency

1.filter precision:0.3-500um

2.MOQ:5pcs

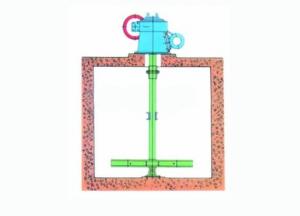

Coalescence Filter for Natural Gas

1.Introduction

coalescence filter has two steps:liqiud -liqiud coalescer, liquid-gas coalescer. The filter layer is made of hydrophobing

material. so the oil without water can go thourgh. water is separated outside.

2.Filter Material

imported coalescing material, sintered wire mesh material, etc.

3.Product Characteristics

a. Multi-layers complex structure filter paper, high filter precision.

b. Large dirt holding capacity, long service time

c. High flow density, reduced fine filter size.

d. Fiber glass layer, good coalescing effect.

e. The filter structure and material meet standard requirements.

f. Many specifications, can meet requirement for different filter precision.

4.Technical Parameters

Service Medium: transformer oil, turbine oil, hydraulic oil, gasoline, diesel oil, kerosene, natural gas, fuel gas, etc.

Filter Precision: 0.3~500μm

Maximum Pressure Drop: 0.6Mpa

Operating Temperature: -200~330oC

- Q: What about the cooling performance of industrial refrigerators?

- expansion valve through small or blocked. The refrigerant will reduce the amount of liquid, the evaporation temperature of the air conditioner is low, and the evaporator fin will be frosted, and the refrigerant will not evaporate. It will continue to evaporate into the air return pipe and compressor. 4

- Q: What are the requirements of industrial dust collector for filter bag?

- it is best to use the most commonly used also by polyester needle felt material produced by the filter bag, is widely used in industrial dust industry etc..

- Q: Does Honeywell have an industrial prefilter?

- Such as industrial waste water, filtration of circulating water, regeneration of emulsion, waste oil filtration treatment, continuous casting water system in metallurgical industry, blast furnace water system,

- Q: Where is the manufacturer of pure water equipment?

- pretreatment, reverse osmosis, water tank, water pump, intermediate water tank, water purification device, EDI pump, UV sterilizer, polishing resin, 0.2 or 0.5 m precision filter, water object (more than 18M Omega.CM) (New Technology

- Q: What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- The best one to find out, write specifications,

- Q: What kind of filtration equipment do you use to treat wastewater?

- Treatment technology of electroplating wastewater containing heavy metal according to the present situation of our current electroplating industry wastewater treatment status statistics and investigation, the main method of 7 different classification:

- Q: The south is well-known, the strength of the production of filter cloth or industrial filter cloth manufacturers?

- Fushun Yue Sheng Industrial filter cloth company

- Q: The features of paper tape filter and disc vacuum filter?

- The paper tape filter can be divided into two major types: gravity tape filter and forced tape filter

- Q: How is the flow rate of an industrial automatic water filter calculated?

- The material and structure of the screen can greatly improve the flow area of the flow, effectively reduce the water resistance of the filter screen, and ensure the reliable operation. No jam, jam or plug occurs.

- Q: What are the categories of industrial water treatment equipment?

- The negative pressure water supply device, analysis deaerator, vacuum deaeration machine, low thermal deaerator, closed type condensed water recovery device, copper and silver ions sterilization, removal of iron and manganese filtration equipment, yellow rust water filter, fiber bundle filter, fiber ball filter, ceramic membrane filter, high chemical oil remover, complete equipment of the circulating water treatment pool, reverse osmosis pure water equipment, water landscape integrated water purification unit, water treatment equipment, industrial water treatment equipment, sewage treatment equipment, are widely used as water treatment equipment in all walks of life in china.

1. Manufacturer Overview

| Location | Henan,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe |

| Company Certifications | NB certificate; Radiation Work License; ASME Certificate; PTFE Sintered Mesh Process |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Coalescence Filter for Natural Gas Compressor Station

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 PieceS pc

- Supply Capability:

- 10000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords