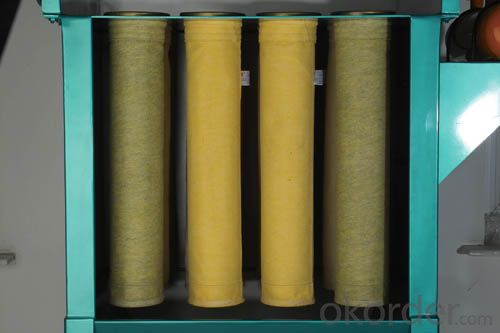

Glassfiber Non Woven dust filter bags for filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview:

Our company can supple all kinds of glassfiber non woven bag filters.

Glass fiber is drawn from melted glass chon rule and is an organic non metallic material. Compared with traditional synthetic fibers, it has high tensile strength and small elongation at break, and very good high temperature resistance and chemical characters. with different chemical treatment and surface treatment, it is a relatively ideal high temperature resistant filtering material, however, glass fiber has bad folding strength and cannot endure relatively large filtering load.

Features:

High temperature

Wear resistance

Break resistance

Long service life

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Specification:

Material | 100% glassfiber |

Weight | >950g/m2 |

Air Perm | 80-150L/m²S |

Warp Tensile Strength | >2000N/5×500px |

Weft Tensile Strength | >2200N/5×500px |

Warp Elongation | <15%< |

Weft Elongation | <15% |

Surge Temperature | 260℃ |

Finishing | ,PTFE |

Chemical Resistance: | Acid excellent |

Alkalis poor | |

Oxidizing Agents excellent |

- Q: What about the cooling performance of industrial refrigerators?

- dry filter part blocked. Blocking the filter will reduce the refrigerant supply, the water cooler evaporation temperature is low, the evaporator fin will be frosted, refrigerant evaporation, flow into the back pipe and compressor continue to evaporate.

- Q: How to choose air filter

- Five, the use of demand: according to the needs of purifying pollutants variety selection of efficient air filter, HEPA has very strong function of purification of soot, suspended particles, bacteria, virus, catalytic activated carbon on odor and harmful gas purification effect is better

- Q: What is the standard for quartz sand filter after filtration?

- Quartz sand filtration is one of the most effective means to remove suspended solids in water, and is an important unit for advanced treatment of wastewater, wastewater reuse and water treatment.

- Q: What are the imported brands, industrial filters and filter elements?. Both Chinese and English are best written. Thank you very much!

- The best one to find out, write specifications,

- Q: How to distinguish industrial cleaning agent?

- . Water industrial cleaning agent is mainly based on surfactant added various other chemicals mixed into water; industrial cleaning agent has been widely used in industrial cleaning plastic, metal products, optical glass lenses (copper, iron, aluminum, steel, zinc alloy, etc.) of all kinds of materials for surface cleaning, oil stains, grease.

- Q: What material is an antiseptic filter? Is there a detailed introduction?

- weak corrosive materials in chemical, petroleum production and urban heating. Such as water, ammonia, oil, hydrocarbons and so on

- Q: How can the filter core of the filter installed in the industrial pipe installation be fixed? Seek professional answers

- There is no dispute until the audit is made.

- Q: How is recrystallization done in industry?

- Before the best feeding, according to the volume of the kettle and the loading factor, the material is well calculated and put into use. Of course, fear of solvent multi throw, before debugging can be appropriate less points, not enough to fill, with a pump, the loss is very small..

- Q: What filter cloth is used for industrial filtration?

- food, pharmaceutical industry use warm water before washing, so as not to bring cloth cloth dirt.

- Q: What type of acid and alkali filter is used in corrosive filtration?

- What specific pumping medium, medium concentration, slot size, amount of treasure - > < plastic filter

Send your message to us

Glassfiber Non Woven dust filter bags for filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches