Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

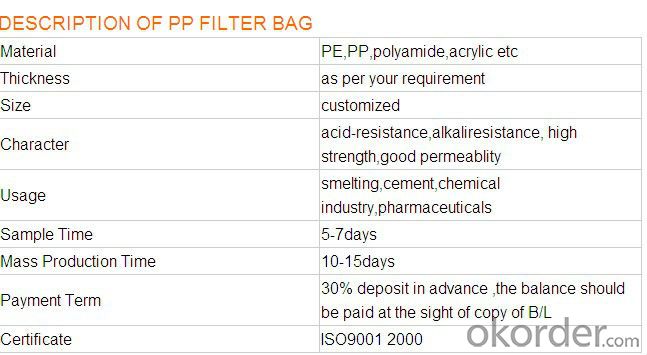

1. Description of Non woven Fiberglass Dust Filter Bag Dust Collector

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Non woven Fiberglass Dust Filter Bag Dust Collector

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Non woven Fiberglass Dust Filter Bag Dust Collector

Weight(g/m2) | 500~550 | |

Thickness(mm) | 2.3~2.5 | |

Air permeability(m3/ m2/min) | 14~8 | |

Tension at break (N/5×20cm) | Warp | >900 |

Weft | >1200 | |

Elongation at break (%) | Warp | <35< span=""> |

Weft | <50< span=""> | |

Working temperature (℃) | Continuous | 130 |

Instantaneous | 150 | |

Anti-acid | Good | |

Anti-alkali | Common | |

Anti-abrasion | Good | |

Post treatment | Thread burning,surface smoothing or coating etc | |

4. Application fields

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

5. Images of Non woven Fiberglass Dust Filter Bag Dust Collector

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: What is the filter principle of the high performance filter bag?

- Mesh structure load the particles block on the surface of filter bag, can reduce the impact of the dust particles on the filter bag and make it easier to blow, prolong the service life of filter bag.

- Q: What kind of bag is used in the food industry

- Food industry USES dust filter bag: general polyester can.I hope my answer will help you.

- Q: Whether the washing machine filter bag is damaged or not

- It doesn't affect the filter bag that can only filter the washing in a wash bucket

- Q: The filter bag is very thick and it's hard to wash everybody how to do it

- The original poster hello! Saline and alcohol don't solve the problem. The most reasonable way to eat jackfruit for years is to use peanut oil. If the mucus of jackfruit is in your hand, you will be able to scrub it with a small amount of peanut oil

- Q: What about the filtering effect of the lubricating oil filter bag

- With the development of the industry, the lubricating oil filter bag is widely used in various fields of industrial occasions, lubricating oil filter bag is one of the most critical steps in the process of the filter.

- Q: What is the reason for the dust bag to be broken for a period of time

- 5, the bottom of the bag is sewn off. 6, the entrance of the filter bag is blown apart. The keel is out of touch. When the blow is out, the filter is putty or broken. Check the quality problem, the filter bag has foreign body or tear

- Q: Choose what aspects to consider when choosing a filter bag

- Class at low temperature, suitable for raw meal grinding, cement mill, such as top bottom library local point of dust bag filter is used, and used in under the condition of high moisture content still need to adopt oil-repellent waterproof treatment on the surface to surface treatment. Often, high temperature, is suitable for the shaft kiln cement and rotary kiln preheater, cooling machine, dryer, etc. The high temperature of waste gas treatment of bag filter, and is used in high temperature, high humidity content under the condition of still need to use oil-repellent waterproof treatment on the surface to surface treatment.

- Q: Does the water in the tank always relate to the washing bag

- Don't wash so often, wash once in a dozen days with the urn, after a few days water is good.

- Q: Who has used a liquid filter bag? What is its feature?

- The dimension stability is good, the fiberglass itself does not contract at the standard temperature Chemical etch is good, acid and alkali resistance.

- Q: How do you check the filter material of the filter bag?

- Physical indicators of filter material, such as the thickness of the filter material, uniformity, quality, air permeability, amplitude, weave organization, the density of woven fabric and nonwoven fabric of bulk density, porosity, etc.

Send your message to us

Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords