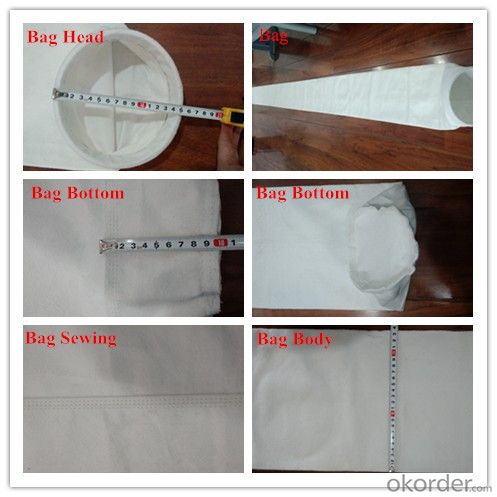

Industrial Nonwoven water proof Polyester Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Packaging & Shipping

Company Information

- Q:What is the fabric of a filter bag?

- Plain weave: this is the simplest form of weaving, every root warp and weft and alternate, but plain weave has disadvantages of difficult to clear ash and easy to jam, as a result, the weaving organization has rarely used for dust removal filter material;

- Q:How do you use a filter bag?

- In order to improve the use of filter bags, we should pay special attention to this knowledge in ordinary times. If we have different problems, we need to find solutions. First, the bag is broken. The shape of the filter bag and the installation method of the filter bag determine the location of the filter bag easily broken, which can be inspected and repaired. Secondly, the filter bags age. For reasons that are caused by the following reasons, reasons should be investigated, taking the elimination measures and changing the filter bags. (1) hardening and contracting due to unusually high temperature; (2) due to contact with the vapor of an acid, alkali or organic solvent; 3) react with water.

- Q:How to unload the washing machine's filter bag?

- The fixed device of a filter bag may be three clasps, and the hard drag is not coming, and you try to use a zig-zag screwdriver to pry into the lock.

- Q:Does the water in the tank always relate to the washing bag

- quarium filter using a filter bag once every three days to wash, the water in the cylinder is always white, if you are completely clean, every time is related to wash the filter bag didn't si; If it's not cleaned, it might be a residue of washing powder, which is a bit of a relationship, but it's not likely because the fish will get sick or die. I think it might have something to do with the fish feed you feed; Or the recent water bleach.

- Q:How to check the filter bag and the dust collector bag when the dust collector is installed?

- Installation of bag filter bag quality inspection is also more important, with the bag cage check: because of the bag filter to board, cooperation between the bag and the bag cage requirements is very high, so when installing the bag cage must strictly control the space between the cage with a bag, bag to fit clearance beyond the technical requirements of replacement at once. Finally after installation of the re-inspection, the bag cage after installation, for all the bag cage installation, check one by one, the quality of the installation, review the top of the bag cage with the bag mouth and bag cage, stable performance.

- Q:Choose what aspects to consider when choosing a filter bag

- Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter. The inside of the filter bag is used to support the filter bag to prevent the bag from collapsing, and it helps to clear and redistribute the dust cake.

- Q:What is the reason for the strong drop in the broken filter bag of the cement mill dust filter bag

- The length of the filter will wear out and reduce dust removal efficiency

- Q:Is there a filter bag for the washer?

- A cylinder washer is not a filter bag. And there's no drain valve, but he has a pump. So where did the dirt go? You can look at the structure of the drainage pump first.In fact, he is a vane pump, so the dirt not sensitive, general MAO flocculant, can be directly into the sewer, there is no need to filter bag, larger smudgy, can open the cover to remove. The experience I've been using for a decade or so is that there is no such thing at all

- Q:How do garbage bags in washing machines have no garbage

- That's because when you wash your clothes the water level is too low, the water can't come up, so you can't filter the water, you can adjust the water level. And the filter bag doesn't work,

- Q:What are the benefits of using a filter bag

- Secondly, the filter bag is made of advanced technology, it is not the phenomenon of the needle eye and it is very good.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Nonwoven water proof Polyester Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches