Double-Side Planer 450mm

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of 450mm Double-Side Planer

1. Cast iron housing frame, stable and shock absorption, NC machining center machined, provided a better foundation for cutting and feeding.

2. Specially and precisely processed main spindle with high precision imported bearings, provided a strong and healthy heart for the machine.

3. Suspended hoding claws on feeding track, accommodated different thickness or bending of the materials, provided powerful feeding capacity.

4. Equipped with manual and automatic fine-adjustment on top cutter shaft, barrels and feeding units, quick and accurate positioning. Linkage top and bottom feeding barrels, balanced and powerful feeding capacity.

Standard Configuration of 450mm Double-Side Planer

1. Made from cast iron for optimal vibration absorption, the massive machine base ensures a smooth running for the cutter spindles and the feeding mechanism.2. Positive upper & bottom feeding rollers for easy, fast and powerful material feeding.

3. Bottom cutterhead pull-out design for convenient and safe knife replacement.

4. Made from special material and specially treated, the cutter spindle is dynamically balanced, characterizes by speedy rotation, high precision and long service life.

5. Auto lubricator provides a forced lubrication to all major transmission parts and sliding parts regularly, features oil-free protection.

6. Feeding mechanism is frequency inverter controlling system, suitable for various material processing.

7. The adjustment of the movable working table is carried out at the machine side for an easy, safe and fast operation.

8. Provided with auto thickness setting device and upper pressure mechanism down limit switch. Put the material on the auto thickness setting device, down the upper pressure mechanism to set the thickness automatically. No repeated thickness adjustment needed.

9. Both the upper & down cutter spindles are designed with cutter spindle locking device,prevents the finger from being hurt during knife replacement.

10. High working precision, excellent quality and wood saving are guaranteed.

11. Provided with magnetic scale digital readout for working thickness adjustment, the working precision is up to 0.01mm.

12. The feeding pressure can be adjusted according to the working condition to prevent workpiece from sliding and avoid any pressing mark on the workpiece surface.

13. Provided with heavy duty helical cutterheads, improves the working efficiency, especially suitable for hard and moisture material processing.

Advantages of 450mm Double-Side Planer

1. Top and bottom active feeding barrels structure with an overload protection, feeding more powerful and stable.

2. Equipped with short material processing device, insured smooth short pieces processing, improve waste wood utilization.

3. Imported main governor equipped with high torque reduction worm gear box, variable feeding speed adjustment to accommodate the actual demand of wood processing.

4. Heavy-duty gray cast iron bousing frame and working table, through aging treatments and precise machining, provided better shock absorption and high accuracy.

5. Feeding mechanism up and down fine adjustment, up to 10mm, highly improved processing accuracy, feeding more powerful.

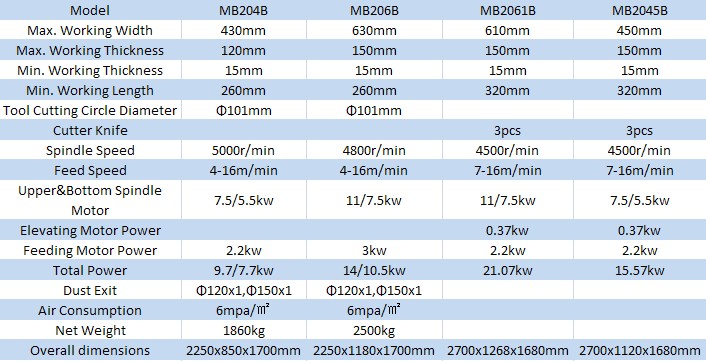

Specifications of 450mm Double-Side Planer

Pictures for 450mm Double-Side Planer

- Q:What tools are needed for interior door mounting carpenters?

- Equipped with torque regulation and restriction mechanism, electric tool for screwing and unscrewing screw. The power tool is mainly used for assembly lines. Is one of the necessary tools for most manufacturing enterprises.

- Q:A woodworking plane how to adjust the use of methods and skills?

- A lying nine, not pushed; Li Wo eight, labor in vain: This refers to the slope in the planer cutter. When the vertical direction is one inch, the horizontal direction of nine points, equivalent angle is 49 degrees, suitable for cutting hard wood, push to dig more lively, general construction site use red pine, cork more, with a lying on a slope, the equivalent angle of 45 DEG C. If the use of standing down eight slope, it will be more difficult to use. Of course, in addition to some special purpose planing, planing slope also need appropriate changes, such as pull planing, slotting plane slope will be smaller; grooving, line planing, slope should be appropriate to increase a little.

- Q:What brand of carbide woodworking planer good quality?

- Hard alloy is widely used as a tool material, such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials.

- Q:A woodworking plane planer installation angle is?

- In the cutter spindle mounted at 30 degrees angle, blade angle in 20 planes to 45 degrees, see materials and planing speed to increase or decrease by cutting edge strengthening processing tool, its service life can be increased by 70%. The better wear resistance of cutting tools.

- Q:How many degrees of ability of woodworking machinery cutter grinding durable

- This perspective with the processing of cutting thickness, coarse plane angle with fine plane angle is different, Never mind with durable, durable is related with the plane iron materials, with timber processing related.

- Q:I have a woodworking planer, the hardness is not enough, how can we strengthen the hardness of it

- Strictly speaking, heat treatment is necessary, but it is of little significance to strengthen hardness if it is only for bad use

- Q:Please hand woodworking planer, the wooden part is what species?

- The commonly used woodworking planer with woodSouth oak wood is dark red, more commonly used materials, high-grade general cargo container frame. Relatively heavy.The Japanese side oak, orange red, is the ideal material.

- Q:How to wear woodworking planer grinding sharper?

- Look at the edge of the knife, there is no sand on the line. Or scrape it on your hands. If it feels fluffy, it's successful; if it feels slippery, you must grind it again. Use the negative side to slow down.

- Q:Who knows the installation method of woodworking planer?

- And a small piece of wood stuck!My father used to be a carpenter. I saw moreSmall pieces of wood should be along with the size bladeSmall wood chip to Guanghua, how can the network even sold together with wood chips?Pressure mounted on the iron screw, and cutter together edge alignment, lies in, pressure in iron, into the plane, again on a wooden wedge.

- Q:Woodworking planer hard alloy cutter to welding

- For welding strength, good wettability and fluidity shall be guaranteed, and foaming shall be eliminated so as to prevent welding from occurring;

1. Manufacturer Overview |

|

|---|---|

| Location | Foshan, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | South America; North America; Africa; Middle East; Russia; Ukraine; Egypt; Asia; Italy; Israel; Uganda; Pakistan; Tunisia; Australia; Southeast Countries |

| Company Certifications | ISO9001:2000; CE;CQC |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Rongqi; Beijiao; Huangpu; Shenzhen |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 1000 - 2000 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 15 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High |

Send your message to us

Double-Side Planer 450mm

- Loading Port:

- Shunde, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1pcs pc

- Supply Capability:

- 1000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords