Industrial Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

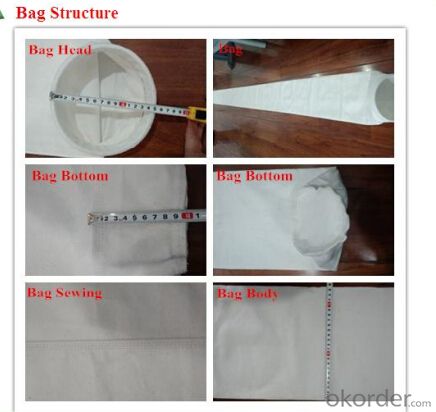

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Antistatic Constructions

electrical conductive

Optimum discharge of electrostatic charges, therefore suitable for potentially explosive areas, as well as for electrostatic, strongly chargeable/charged dusts.

permanent electrical conductive in accordance with DIN 54 345 part 1 by adding stainless steel fibres into the fibre mass in accordance with DIN 54 345 part 1 or

alternative in support of scrim in accordance with DIN 54 345 part 1 and part 5

Packaging & Shipping

Company Information

- Q: How can the washing machine's filter bag be clean?

- In general, the filter bag of the washing machine can be removed, please read the instructions carefully, even if it is not easy to tear open come down to, as long as don't have much stuff, generally does not affect the quality of washing.

- Q: How do you clean a filter bag with oil stains?

- 1, the oil pollution in the filter bag is required to remove the oil by hand. 2, USES the high frequency vibration, will enter the filter filter bag inside the wall of the larger dust particles removed, will not affect fiber entanglement of fastness, keep the filter bag is good, easy tear of dirt. 3, extract the bag samples, using the professional instrument laboratory detection filter filter bag oil composition, to adapt to washing raw materials, the maximum cleaning filter bag and without causing any damage to the filter bag. Select the appropriate chemical preparation to soak the filter bag, remove the grease stain from the filter pocket, and increase the ventilation performance of the filter bag. Choose the appropriate washing materials and strict proportion. Low temperature water cleaning, the water is uniform, the strength is moderate, no mechanical damage to the filter bag. Use 110 degrees Celsius to heat air to dry, keep the size stability of the filter bag, and the filter bag is not deformed after drying. Finally, repair the damaged filter bag. The cleaning bag is basically the same as the new filter bag.

- Q: How clean is the bag filter bag

- According to the mechanism of liquid filtration process, surface filtration and deep filtration are classified.

- Q: What kind of bag is used in the food industry

- Food industry USES dust filter bag: general polyester can.I hope my answer will help you.

- Q: How do you pack the filter bags in the washing machine

- Can observe filter plate have an arrow above, according to the location of arrows, have hands press card, can win filter, fasten can directly when installation;

- Q: What is the cause of the liquid filter bag

- Pressure problem: operating pressure is within the scope of the permit, the differential pressure to be executed in accordance with the relevant provisions, there are two ways to look at the differential, a mechanical pressure gauge is relatively low, but the error is very large, another is the flowmeter, costs a little high.

- Q: What about the filtering effect of the lubricating oil filter bag

- With the development of the industry, the lubricating oil filter bag is widely used in various fields of industrial occasions, lubricating oil filter bag is one of the most critical steps in the process of the filter.

- Q: How to use a home cleaner filter bag properly

- Important problems in maintenance. Use a vacuum cleaner to clean the carpet to move in the direction of the wool of the carpet, so absorb dust to maintain the level of carpet wool, It won't break the carpet.

- Q: What is the effect of a dust filter bag?

- The second is that the filter bag has gravitational sedimentation. Thermal motion; The role of inertial forces; Sieve filters and so on

- Q: How about the filter bag of the washing machine

- One hand holds the middle position in the net and the other hand is pressed from the lower pressure, which can be removed and must be careful not to break the card. Note: to prevent filtering or filter box breeding bacteria, it is recommended that users be taken apart.

Send your message to us

Industrial Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords