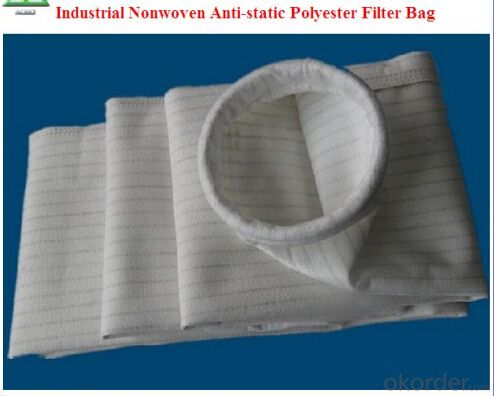

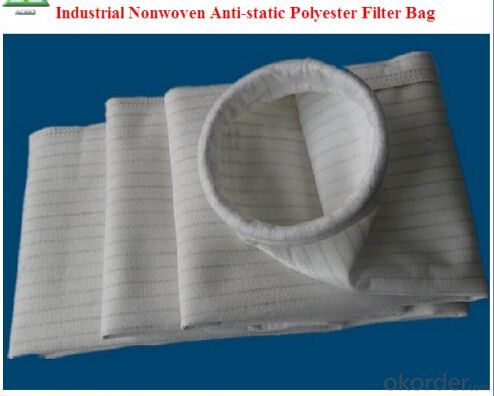

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

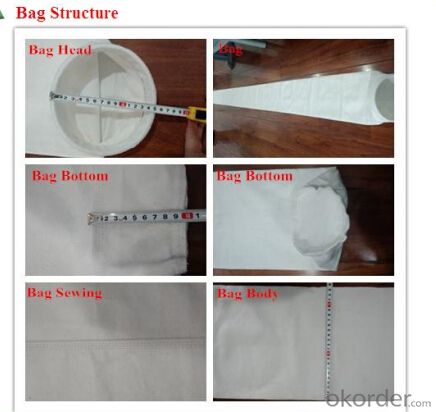

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

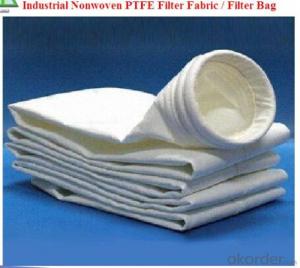

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Antistatic Constructions

electrical conductive

Optimum discharge of electrostatic charges, therefore suitable for potentially explosive areas, as well as for electrostatic, strongly chargeable/charged dusts.

permanent electrical conductive in accordance with DIN 54 345 part 1 by adding stainless steel fibres into the fibre mass in accordance with DIN 54 345 part 1 or

alternative in support of scrim in accordance with DIN 54 345 part 1 and part 5

Packaging & Shipping

Company Information

- Q: How clean is the bag filter bag

- Deep depth with felt filter material, filtering is a compound intercept model, namely the larger particles impurities trapped in the fiber surface, and tiny particles are trapped in deep in the filter material, so the filter with high filtration efficiency. Deep filtration cannot be cleaned and reused

- Q: The filter bag in the washing machine is broken. How do you fix it

- In general, the filter bag of the washing machine can be removed, please read the instructions carefully, even if it is not easy to tear open come down to, as long as don't have much stuff, generally does not affect the quality of washing.

- Q: How many types of filters are in the filter bag?

- Circular: dust filter bag is a cylindrical shape. Its specifications are expressed in diameter by length, which is D by L (mm).

- Q: Does the water in the tank always relate to the washing bag

- Don't wash so often, wash once in a dozen days with the urn, after a few days water is good.

- Q: How to choose a liquid filter bag

- 1, first of all, according to the chemical name to filter the fluid, according to the chemical with taboo to find available filter material, commonly used in PE, PP, PTFE, NMO, again according to its operating temperature, operating pressure, ph, operating conditions (such as whether to need to tolerate steam, hot water or chemical sterilization, etc.), assessed and eliminate shall not apply to the filter material. Use is also an important consideration, such as pharmaceutical, food or cosmetic ingredients that must be approved by the FDA; Ultra-pure water should be chosen for pure and not contain the filter material that will affect the impedance. Filter gases should be selected for hydrophobic materials and whether "health grade filtering" design is required. The main foreign Filter bags are GAF, FSI, 3M, CUNO, U.S. Filter, LOEFFLER, PARK, Vablue Filter bag etc

- Q: How can you not damage the filter bag when the filter bag is installed?

- The dust filter bag has a great effect on the dust removal effect, and the filter bag must not be damaged by the installation. 1 should pack the filter bags to the installation location and install one of them. The filter bag cannot be dragged carelessly on the board, to prevent the metal burrs from the surface of the filter bag, and damage the filter bag. Remove from the packing box until it is installed to the orifice of the flower plate, not touching any metal or surface roughness. Use the protective cover provided by the supplier when using the orifice, in case the filter is touching the plate hole.

- Q: How to use a home cleaner filter bag properly

- Beware of using filter bags to absorb inflammable and explosive items or things that are hotter, so as not to burn or explode. The dry cleaner can't absorb the liquid, and the average household vacuum cleaner also tries to avoid the metal scraps, otherwise it's easy to absorb dust The device causes damage and affects performance. Dust bag vacuum cleaners should stop vacuuming immediately and replace them immediately to prevent dust from causing damage. It should not be used for long periods of time, and if used for a period of time, dust accumulates in the filter bag causing the suction to drop and can be shaken Moving the box, the dust is knocked down at the bottom of the box, and the suction will recover.

- Q: Can liquid filtration bags be cleaned and reused

- Deep depth with felt filter material, filtering is a compound intercept model, namely the larger particles impurities trapped in the fiber surface, and tiny particles are trapped in deep in the filter material, so the filter with high filtration efficiency. Deep filtration cannot be cleaned and reused.

- Q: How do you check the filter material of the filter bag?

- Special features: the properties of heat resistance, abrasion resistance, flame retardant, antistatic properties, corrosion resistance and hydrophobic properties. Membrane filter: check the membrane strength.

- Q: How do garbage bags in washing machines have no garbage

- Check the wheel. If it's broken, you should ask the professional to fix it.

Send your message to us

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords