Needle Punched Nonwoven Acrylic Dust Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Needle Punched Nonwoven Acrylic Dust Filter Bag

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton), Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Needle Punched Nonwoven Acrylic Dust Filter Bag

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Needle Punched Nonwoven Acrylic Dust Filter Bag

| HZ Filter | REF CODE: SY-500 | ||

| NAME: Acrylic filter felt | |||

| Fiber Material | Acrylic | ||

| Scrim Material | Acrylic staple yarn | ||

| Weight | GSM | 500 | |

| Thickness | MM | 2.1 | |

| Airpermeability | L/dm2/min | 120 | |

| Tensile strength | Warp | <=N | 600 |

| Weft | <=N | 1300 | |

| Break Elongation | Warp | <% | 30 |

| weft | <% | 30 | |

| Work Temp | Continuous | <°C | 140 |

| Peak | <°C | 160 | |

| Finishing | Heatset/carlender/singe /water+oil repellent/Film laminating available | ||

4. Application fields of Needle Punched Nonwoven Acrylic Dust Filter Bag

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

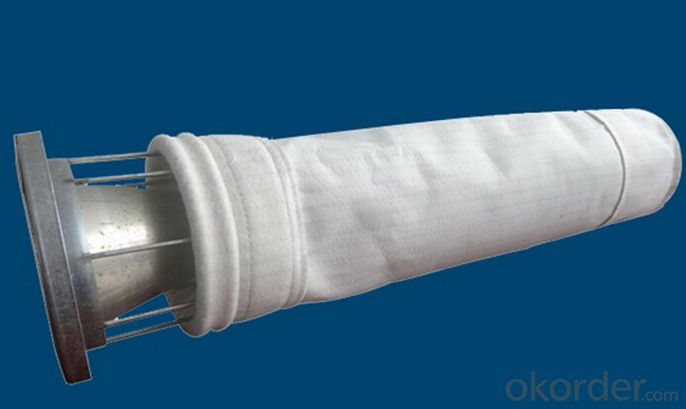

5. Images of Needle Punched Nonwoven Acrylic Dust Filter Bag

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: What materials are used for the air filter bag?

- low resistance, large dust capacity, high filtration precision, convenient replacement, products are widely used in automotive electronic, pharmaceutical, food, the central air conditioning ventilation system of centralized air filtration, to ensure the cleanliness of pipeline.

- Q: Where do you sell filter bags in Zhengzhou?

- Zhengzhou Kaida environmental protection technology manufacturers selling all kinds of cloth bag, dust bag, reliable quality, reasonable price, please contact the online search

- Q: What does the filter bag filter? What's the principle?

- Washing sheets and bedding bags is the most obvious, there will be a lot of fur collected, useful.Remember to clean it up regularly, not germs.

- Q: Figure out how to remove the Little Swan double cylinder filter bag

- Otherwise, to burnThe best thing to do is to contact the mall first. Your problem may be that the drainage hook is too tight. But for whatever reason, you shouldn't try too much, unless the mall staff ask for it. Anyway, customer service service is free, do not be afraid of trouble!!! 7 days 15 days

- Q: PP filter bag can be used in which industry, filtering effect? Solving!!

- According to my experience, PP filter bag has a wide range of applications, such as automotive coatings, paint, pharmaceutical, catering, water treatment, etc., can be used for filtration, filtration effect, and strong retention.

- Q: How many filter bags does the Little Swan Washing machine have?

- I don't know what to say, but if you look closely, you'll know what happened.

- Q: For tea or tea or seasoning stew when placedWhat I want is a small paper bag, not one of those stainless steel boxes

- Farm product marketSupermarketConstantOld East GateWest MarketAll small stalls selling household goods are soldSupermarkets are expensive

- Q: Automobile transportation paint paint filter bag how to choose

- The cleaning machine is widely used in the field of industrial cleaning, car factory should also prepare some cleaning machine, paint, welding slag, the effect is quite good, I suggest you use the Chengdu Lifeng cleaning machine, cleaning machine not only to look at the management and maintenance of the latter, choose a...Have to use car repair paint, then I suggest still good ground treatment, spraying varnish. In accordance with the plastic coating process, painting, in addition, do not bake, it will be deformed. There is also a choice, but also a better choice. To the auto parts city or paint shop, etc....Cleaning machine in the field of industrial cleaning has a very wide range of applications, the car factory should also prepare several units, cleaning machine wash, paint, welding slag effect...

- Q: What's the effect of lubricating oil filter bag filtration?

- Lubricating oil filter bag is used in various types of machinery to reduce friction, protection of machinery and processing parts of liquid lubricants, mainly from lubrication, cooling, rust, cleaning, sealing and buffering.The lubricating oil filter bag has many advantages, such as simple and reasonable structure, good tightness, good circulation ability and easy operation.

- Q: What is the best way to use a filter bag?

- Fifth, replace the filter bag, first use compressed air blowing, and then check whether there is a broken hole, there are broken holes after the repair to be replaced. If the filter bag that is stuck by dust, rinse with water and replace after cooling.Sixth, filter bag blocked. When the filter bag is blocked, the resistance is increased, and the reading of the pressure differential meter can be increased. Clogging of filter bags is the main cause of wear, perforation and falling off of filter bags.

Send your message to us

Needle Punched Nonwoven Acrylic Dust Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords