Nylon Liquid needle felt filter bag for water treatment and water purification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

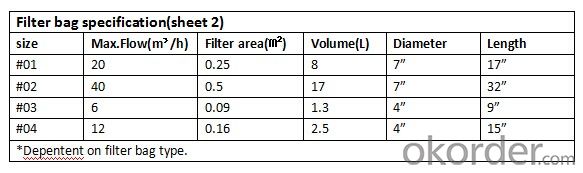

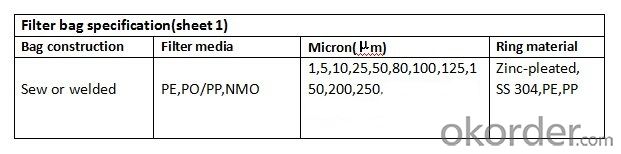

Nylon monofilament filter bag are using high strength nylon mesh and sewing. Absolute accuracy level, filter than its mesh big magazine trapped on the material surface; diameter less than mesh particle passes through the mesh into downstream. Therefore, nylon monofilament filter the filter surface and smooth surface is convenient for cleaning, can be used repeatedly. nylon monofilament filter bag in the production process adopts unique wrapping or lining non-woven technology and in the maximum extent to prevent leakage stythe eye of a needle.25-2500 microns seam monofilament nylon bag filtration precision scope, the pockets with stainless steel ring, galvanized steel, PE / PP engineering plastic sealing rings.

PP filter bag(Micron Polypropylene filter fabric) have a lower fiber release, more defined pore size and greater retention efficiency than other filter media(filter bag). Liquid PP filter bag offer high efficiency filtration and have a high solids catch capacity. Produce micron Polypropylene filter bags have their outside surface singed or glazed to prevent fabric fiber from the bag getting into the clean,filter process media. Micron PP filter bags are generally compatible with most fluids except those considered aromatic solvents or strongly alkaline.Liquid PP filter fabric(liquid PP filter bags) are recommended for prefiltering acids,aqueous and most solvent solutions.

- Q: How to choose material for filter bag of dust collector?

- And on the flue gas temperature is relatively high places, such as chemical industry, carbon black (silica) exhaust, BF gas, shaft kiln cement plant exhaust, calcium carbide plant, steel plant, forging furnace exhaust gas, asphalt mixing asphalt and refractory brick kiln flue gas furnace flue gas, coking gas smoke, one is because of these dust due to dust specific resistance limit is not suitable for electric dust collection, can only use the dust bag or other methods;

- Q: What should be done for the quality inspection of the dust filter bag?

- Filter dust layer also has a certain filtering effect, dust filter bag cleaning. Because of the use of the resulting abrasion, holes and other damaged filter bags for repair, to ensure a high rate of reuse.The instrument is used to check the cleaning bag to ensure the cleaning quality. Through the processing of the above process, the filter bag after cleaning can completely meet the application requirements

- Q: In fact, no matter the dust filter cartridge or the filter bag, the main design is reasonable, so as to achieve the desired effect.

- The bag has chemical stability and excellent heat resistance, is applied to filter the highest performance in the industry, but also all of the common filter materials performance of the most high-end varieties, the filtering efficiency and accuracy has reached a higher level. Commonly used filter materials are PE, PP, PTFE, PMIA, NMO and so on. Chinese filtration precision filter bag filter bag with a precision of properties of chemical stability and heat resistance performance of PE filter, PP, PTFE, PMIA, NMO 1 features 2 performance advantages directory 3 bag use 4 commonly used cleaning method of filter bag 5 Classification 6 bag type dust remover 7 commonly used after treatments of 8 caused by dust 1 Characteristics of bag bag damage is a key part of the operation process in the bag type dust collector, usually vertical cylinder type filter bag dust hung in. The fabric and design of the filter bag should aim for high efficiency filtration, easy dust stripping and durable effect. In pulse and box type pulse dust collector, the dust is attached to the outer surface of the bag. When dust laden gas passes through the dust collector, dust is caught on the outer surface of the filter bag, and the clean gas enters the filter bag through the filter material.

- Q: Why dust filter bags covered with plastic film?

- The service life of the bag can be extended and the resistance in the operation of the bag can be reduced

- Q: I was in Huizhou, there is a problem ask you heroes, is a common household washing machine, bag inside the drum has a white filter water. With a long time on the broken, I have been looking for many places can not find, who can tell you what? I believe many people also have this demand. Thank you

- Filter bag broken, the general border is good, you can make their own: waste will be stockings cut into the size of the appropriate bag, fixed to the border on the line.

- Q: Parameters of dust filter bag material

- The surface smoothness of the filter material has a great influence on the dynamic resistance of the filter material. The initial resistance of the filter depends on the permeability of the filter itself, while the resistance in operation is much larger than the initial resistance.

- Q: Does power xpb25-2538s have filter bags?

- the filter material: nylon, polypropylene, polyester, stainless steel, PTFE, filter size according to distinguish between: No. 2, No. 1 bag bag, 5 bags, 4 bags, 3 bags (from large to small), the other is non-standard.

- Q: Automobile transportation paint paint filter bag how to choose

- Ha ha, it's easy for me. I need the filter material from the painting workshop to answer ha. Pretreatment and electrophoresis line requires the following: 1, filter material filter (the tank filter required) 2, phosphate slag filter / belt (phosphate slag filtration system requires the use of 3), biofilm (electrophoresis generating filter membrane ultrafiltration need coating),...Oil removal powder core 1, powder masterbatch formulation: degreasing powder core + powder masterbatch (soda and soda, sodium silicate, alkaline water can be) 2 Formula: degreasing powder core masterbatch + Super Almighty surfactant + drawing powder + water + water + antiseptic flavor 3, neutral formula: Super nano emulsion agent + super oil emulsifier + drawing powder + water + + 4, alkaline paste flavor preservatives...The best two together, so that water can not go to paint, in fact, look at where you used it, ~2 the effect should be the same

- Q: What is the reason that the filter bag is broken and the strength of the filter bag is decreased greatly in the cement plant?

- Three, wear. There are three reasons for the bag filter wear:1. uneven distribution of air flow. Uneven distribution of air flow results in high velocity scouring of filter bags with dust smoke, local wear of filter bags and lower service life.2. flue gas filtration rate is high. Excessive filtration rate of the flue gas will cause frequent soot cleaning, and the fabric, fiber, especially glass fiber of the filter bag will be damaged easily.3. filter bag spacing is too small. The wearing of the lower part of the filter bag is a common phenomenon. The wear is on the one side, the lower part is the most serious, and it gradually decreases. The local sewing thread will be worn off.

- Q: What's the effect of lubricating oil filter bag filtration?

- The filter bag has the advantages of small lateral leakage probability, accurate filtration accuracy and quick replacement of the filter bag. The inner and outer surfaces of the lubricating oil filter are treated by mechanical sand blasting, which is uniform and easy to clean.

Send your message to us

Nylon Liquid needle felt filter bag for water treatment and water purification

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches