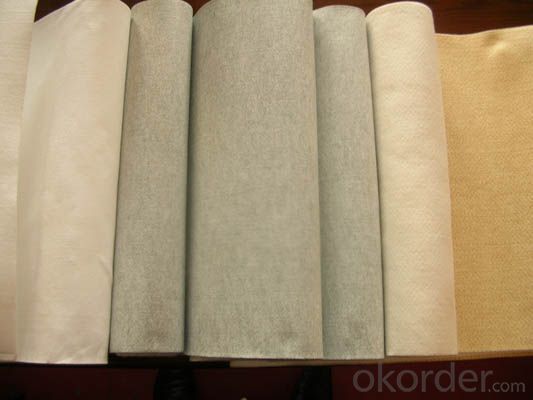

Acrylic Non Woven dust filter bags for dust filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview:

Acrylic Non Woven Bag Filter has the good abrasive resistance.

Our company can offer all kinds of Acrylic non woven bag filters. Acrylic filter bag is most widely used in the temperature between 125 centigrade and 145 centigrade. it has relatively good chemical corrosion tolerance and hydrolysis tolerance, can be normally used under the condition of PH between 3-11. Compared with other filter cartridge, it also has better acid resistance, alkali resistance. They are excellent used in chemical working conditions of dust treatment and recycling.

Features:

Good thermal resistance needle felt

Good air permeability filter bag

High precision of filtration

We pursue quality products, reasonable price and excellent service.

When you choose to use the products of our company, you only need to call or write to the company, we will solve all you troubles and give you a satisfactory results.

Specification:

Material | 100% acrylic |

Weight | 550±30g/m2 |

Air Perm | 100-160L/m²S |

Warp Tensile Strength | >850N/5×500px |

Weft Tensile Strength | >900N/5×500px |

Warp Elongation | <35%< span=""> |

Weft Elongation | <45%< span=""> |

Continuous Temperature | 135℃ |

Surge Temperature | 145℃ |

Moist Temperature | 125℃ |

Finishing | Singed, smooth, stabilization |

Chemical Resistance: | Acid good |

Alkalis Fair | |

Oxidising Agents Good |

Acrylic media will irreversibly shrink at elevated temperature. To avoid such occurrences please operate in an environment in according with the above recommendations.

- Q: What is the scale of industrial circulating water system and what method or equipment is used to remove scale?

- t reduces the heat exchange efficiency and affects the normal operation of the system. Therefore, the main problems of cooling circulating water are scale, dirt, corrosion, algae, pipe network corrosion and concentration control.

- Q: What are the famous water treatment plants in China?

- Main applications: textile printing and dyeing, paper making water, chemical reagent production, pure water. Pure water for skin care product, shampoo for producing pure water, hair dye for producing pure water. Chemistry laboratory, physics laboratory, biology laboratory.

- Q: Can industrial oil mist filter be discharged indoors directly?

- while the industrial oil mist filter bodi is in accordance with the standards of design

- Q: Principle of on-line self-cleaning filter for industrial water treatment and forced backwashing

- wash wash is put into operation before the preparation work is mainly to restore contact filter filtration and depth filtration effect, to ensure the water quality of medium SDI (pollution index) = 4.

- Q: Which brand of household activated carbon filter is good?

- to meet the requirements of the filter accuracy of the hydraulic system, to prevent certain impurities into the system;

- Q: What equipment is used for oil (cooling) in filtration equipment?

- adding the third element in the two yuan in the alloy, will change the solubility of the original alloy component, or even a new phase of the new generation phase transition.

- Q: Method for treating manganese sand filter

- And used in the swimming pool circulation treatment system, cooling circulating water purification system and so on.

- Q: Do I need to add a filter before the industrial circulating water pump?

- If after cleaning and pre film, the filter blockage will be reduced, and often do not clean, but the import filter is still needed,

- Q: What are the categories of industrial water treatment equipment?

- The following water treatment equipment: automatic dosing equipment, automatic water softener, mechanical filter, reverse osmosis equipment, pure water equipment, ultra pure water equipment, hollow fiber ultrafiltration device, ion exchange, polishing mixed bed, mixed bed, EDI electric desalting system equipment, drinking water equipment factory, bag filter

- Q: Application range of quartz sand filter

- can be widely used in electronics, power, petroleum, chemical, metallurgy, electroplating, paper making, textile, pharmaceutical, dialysis, food, beverages, drinking water, factories, enterprises, water, swimming pool, etc.. Can meet the needs of liquid filtration in various industries.

Send your message to us

Acrylic Non Woven dust filter bags for dust filtration

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords