Nonwoven Polyester Dust Bags for Vacuum Cleaner

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Nonwoven Polyester Dust Bags for Vacuum Cleaner

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Nonwoven Polyester Dust Bags for Vacuum Cleaner

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Nonwoven Polyester Dust Bags for Vacuum Cleaner

| Material | Polyester | |

| Weight(g/m2) | 550g/m2 | |

| Thickness(mm) | 2.0+/-0.2 | |

| Air permeability(m3/m2*min) | 15 | |

| Tensile Strength(N/5*20cm) | Warp | ≥1000 |

| Weft | ≥1100 | |

| Elongation(%) | Warp | ≤35 |

| Weft | ≤40 | |

| Working Temperature | 130degrees | |

| Peak Temperature | 150degrees | |

| Finishing Treatment | Singed,Calendering,PTFE membrane,anti static,water and oil proof | |

4. Application fields of Nonwoven Polyester Dust Bags for Vacuum Cleaner

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

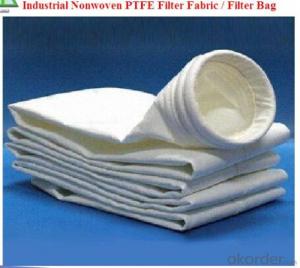

5. Images of Nonwoven Polyester Dust Bags for Vacuum Cleaner

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: What are the benefits of using a filter bag

- It is. Finally, there is a kind of liquid filter bag, the filter bag is used in the welding technology of stainless steel, greatly reduces the probability of filter bag sliding sideways, this technique can well improve the sealing of filter bag, reduce error, seal degree is high

- Q: Whether the washing machine filter bag is damaged or not

- It doesn't affect the filter bag that can only filter the washing in a wash bucket

- Q: What are the advantages of fiberglass filter bags

- It is used in cement factory. The advantage is that it is resistant to high temperature and corrosion.

- Q: What are the textures of the liquid filter bag

- Nylon net has high strength, wear resistance, chemical resistance, water resistance, flexibility is good, because the wire diameter uniformity, smooth surface, so the ink through sex is also very good. It is not very stretchable by nylon. This kind of screen is in a period of time after the stretch net, the tension is reduced, make the screen plate is relaxed, the precision is reduced. Therefore, it is not suitable for the printed circuit board and so on.

- Q: What about the filtering effect of the lubricating oil filter bag

- The lubricating oil filter bag has many advantages such as simple structure, reasonable sealing, strong circulation ability and easy operation. Especially filter bag side leakage probability is small, can ensure the filtration precision accurately, and can change the filter bag quickly. The surface of the lubricating oil filter adopts mechanical sandblasting and polishing, which is uniform and easy to clean.

- Q: How about all the filters in the washing machine

- Diy, with thick silk stockings points instead of filter bag, the general look on filter bag frame of a quadrilateral layering pressure filter bag, be careful to pick it out, to cut the size of the filter bag, pressed firmly clip flat on back frame can use. New ones are easier to sell.

- Q: What is the filter bag for the washing machine?

- Filtration of all kinds of fine dust that fall on clothing during the laundry process: hair, thread, paper, and other impurities Washing sheets and bedding are the most obvious, and there's a lot of hair that's been collected and useful. Always clean up and don't cause germs.

- Q: Who has used a liquid filter bag? What is its feature?

- The filtration efficiency is high, can reach more than 99.5% Expanding filter cloth (bag), improving filter wind speed and filtration efficiency, reducing the volume of dust removal equipment

- Q: What do you notice when the filter bag and dust collector are installed?

- Installation filter filter bag filter bag method is to filter by housing plate hole into the bag in the room, and then put the upper mouth of the spring coil to knead into a pit, in the case of orifice plate medium, neutralizing spring coil again, make it tight pressure tight in the hole on the circumference of a circle, finally the bag cage from mouth gently insert, until the upper part of the filter bag cage cover is pressure on the casing plate hole.

- Q: How do you check the filter material of the filter bag?

- Filter bag dust filter core, its quality directly reaction precipitator dust removal efficiency and service life, in order to ensure the quality of filter bag, cope with the production of filter bag filter material for sampling, determine its performance up to standard. The filter material needs to be tested and tested: 1, the appearance of filter material: observe whether there is a jumper line, defect, puncture, black spot, joint, broken line, etc. 2, the mechanical properties of the filter material: testing the tensile strength, elongation at break of filter material, warp/weft direction of the load elongation and burst strength of filter bag is in line with the standard.

Send your message to us

Nonwoven Polyester Dust Bags for Vacuum Cleaner

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords