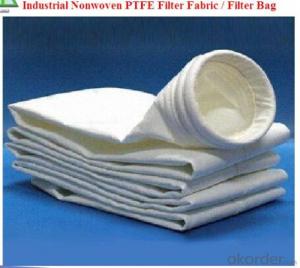

High temperature filter bag fiberglass needled felt filter bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of High temperature filter bag fiberglass needled felt filter bag

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of High temperature filter bag fiberglass needled felt filter bag

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of High temperature filter bag fiberglass needled felt filter bag

Nonwoven dust filter bag | Continuous Temperature | Peak Temperature | Description | Resistance to Acids | Resistance to Alkalis | Resistance to Oxidation | PH Value |

Polypropylene | 90°C | 100°C | PP | excellent | excellent | restricted | 1-14 |

Acrylic | 125°C | 140°C | AC | good | good | good | 3-11 |

Yadi | 150°C | 160°C | Yadi | excellent | excellent | excellent | 3-13 |

Polyester | 130°C | 150°C | PE | restricted | moderate | good | 4-12 |

Polyphenylensulfide | 190°C | 200°C | PPS | excellent | excellent | moderate | 1-14 |

Nomex | 204°C | 250°C | Nomex | good | excellent | good | 3-14 |

Polysulfonamide | 250°C | 300°C | PSA | excellent | excellent | excellent | 3-14 |

Polymide | 260°C | 300°C | P84 | good | moderate | good | 3-13 |

Polytertrafluoroethylene | 250°C | 280°C | PTFE | excellent | excellent | excellent | 1-14 |

Glass fiber | 260°C | 300°C | BQ | good | good | good | 3-11 |

4. Application fields of High temperature filter bag fiberglass needled felt filter bag

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

5. Images of High temperature filter bag fiberglass needled felt filter bag

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: What is the filter principle of the high performance filter bag?

- The network structure of nanofibers can reduce the thickness and line density of the supporting filter, thus reducing the pressure loss and improving the efficiency of production.

- Q: What is a good filter bag?

- However, the loop suture of the filter bag can be a single line, but it needs to be sewn more than two times.

- Q: What about the filtering effect of the lubricating oil filter bag

- The lubricating oil filter bag has many advantages such as simple structure, reasonable sealing, strong circulation ability and easy operation. Especially filter bag side leakage probability is small, can ensure the filtration precision accurately, and can change the filter bag quickly. The surface of the lubricating oil filter adopts mechanical sandblasting and polishing, which is uniform and easy to clean.

- Q: What is the filter bag for the washing machine?

- Filtration of all kinds of fine dust that fall on clothing during the laundry process: hair, thread, paper, and other impurities Washing sheets and bedding are the most obvious, and there's a lot of hair that's been collected and useful. Always clean up and don't cause germs.

- Q: What is the fabric of a filter bag?

- Plain weave: this is the simplest form of weaving, every root warp and weft and alternate, but plain weave has disadvantages of difficult to clear ash and easy to jam, as a result, the weaving organization has rarely used for dust removal filter material;

- Q: What is the correct way to use a filter bag

- Fifth, replace the filter bag, blow clean with compressed air first, check for broken holes, and then replace when the holes are repaired. If the filter bag is filled with dust, rinse with water and leave after cooling. Sixth, the filter bag is blocked. When the filter bag is blocked, the resistance is raised, but the reading of the differential gauge is displayed. The filter bag jam is the main cause of the wear, perforation and loss of the filter bag.

- Q: What materials are commonly used in liquid filtration bags?

- 1, good heat resistance, can be used under 280 ℃ for a long time Dust is easy to peel off The dimension stability is good, the fiberglass itself does not contract at the standard temperature

- Q: What are the features and methods of using filter bags?

- Self-flow open filtering: the filter bag is directly connected to the pipe by suitable connectors, and it is filtered by the differential pressure differential. It is characterized by the need not to invest in the equipment, the filter is simple and feasible, especially suitable for small specification, various kinds, intermittent type of economical liquid filtration

- Q: Can liquid filtration bags be cleaned and reused

- Surface filter mainly adopts nylon monofilament filter bag, metal wire mesh filter bag), the surface of the filter the way for the hole interception, the interception of impurities in the filter material surface, the surface of the filter can be cleaned and secondary use. Remind: liquid filter bag this is a one-time product, under normal circumstances do not recommend repeated use, repeated use of a filter bag filter failure caused easily, at the same time also can cause cross contamination.

- Q: How to check the filter bag and the dust collector bag when the dust collector is installed?

- Installation of bag filter bag quality inspection is also more important, with the bag cage check: because of the bag filter to board, cooperation between the bag and the bag cage requirements is very high, so when installing the bag cage must strictly control the space between the cage with a bag, bag to fit clearance beyond the technical requirements of replacement at once. Finally after installation of the re-inspection, the bag cage after installation, for all the bag cage installation, check one by one, the quality of the installation, review the top of the bag cage with the bag mouth and bag cage, stable performance.

Send your message to us

High temperature filter bag fiberglass needled felt filter bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords