machine for make PVC pipe/PVC Pipe Manufacturing Plant/PVC Pipe Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

PVC Pipe Making Machinery For PVC Pipe Extrusion China Good Quality 75-200mm

Machine Application

Such qualified extrusion line is mainly for producing PVC agricultural water/ building water/cable pipes, etc.

It can process various soft and rigid PVC, especially process powder directly into pipe shape.

Whole line consists of material feeder, conical twin screw extruder, die head, vacuum calibration tank, haul-off, cutter, stacker or belling machine, etc.

Machine List

| No. | Item | Qty |

| 1 | Screw feeder | 1 set |

| 2 | SJZ 80/156 Conical twin screw extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum calibration tank | 1 set |

| 5 | Three claws haul-off | 1 set |

| 6 | Planetary cutter | 1 set |

| 7 | Stacker | 1 set |

| Option | Belling Machine | 1 set |

Annotation: Some configuration and material can be designed according to customers’ requirement. | ||

Improvements made on Conical twin screw extruder:

1.Gear box bearings: NSK, Japan

2.Gear box: Jiangyin Brand

3.Special design of screw & barrel

4. All connector, nut etc all adopt nickel plated

Electrical part:

1. Solid state relay: Crydom, USA brand instead of common AC contacto

2. Siemens PLC controlling system

3. Pressure sensor: Dynisco,USA

4. Sayu cooling fan, Taiwan brand

5. ABB550 inverter

6. Siemens Beide motor

7. Low voltage component: Siemens/Schneider/LG

Corresponding Advantages:

1. Ensuring long-time stable operation & long service life

2. Compact structure, low noise, high bearing capacity, high transmission efficiency, ensuring long-time stable operation & long service life

3. Heating is controlled by Solid State Relay (S.S.R), realizing stable heating; (SSR) no spark & no noise improve safe production.

4. Siemens PLC controlling system with reliable technology, automatic and intelligent functions for centralized control and monitoring extrusion lines, which helps easy operation.

5. International brand of electronic parts guarantee stable operation and long service life.

Technical Data

Extruder | Pipe ranger (mm) | Max.output (kg/h) | Max.hauling speed (m/min.) | Extruder powder (KW) |

CAMX51/105 | 16-40 Dual | 120 | 10 | 18.5AC |

CAMX65/132 | 20-63 Dual | 250 | 15 | 37AC |

CAMX51/105 | 20-63 | 120 | 15 | 18.5AC |

CAMX65/132 | 50-160 | 250 | 8 | 37AC |

CAMX65/132 | 63-200 | 250 | 3.5 | 37AC |

CAMX80/156 | 160-315 | 350 | 3 | 55AC |

CAMX92/188 | 315-630 | 800 | 1.2 | 110DC |

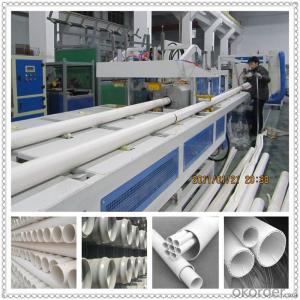

Product picture

FAQ:

Q: What price terms you offer?

A: FOB, CIF, EXW, L/C at sight and other price terms based on your kind request.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: How can we visit your company and machines?

A : Our factory is in Tangqiao Town, Zhangjiagang City, Jiangsu Province, China. About 2.5 hours from Shanghai Pudong International Ariport! We will arrange to pick you up from Shanghai.

A: Yes, our engineers will guide machine installation and train your workers.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Plastic is a chemical product, and the waste gas produced by the process is organic waste gas. The commonly used and relatively efficient treatment method is activated carbon adsorption. The specific work process is as follows: exhaust gas, air pipe, dry filter, activated carbon adsorption, fan and discharge

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- The temperature tolerance of the process file is too lowChanges in the formula of plastics lead to changes in processing temperatureThe workshop operator failed to execute the document

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip two: choose topics based on your interests. The title selection and refining skills of the two, is from the author's hobbies and interests, only conform to the topics and interests, the author accumulated data can work normally, language applications can also Practice makes perfect.

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q: There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- Fan, water pump at low speed, torque is not enough, resulting in high current, if vector control can be ideal.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- See section - cross section. Setting adjustment with RPC

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

Send your message to us

machine for make PVC pipe/PVC Pipe Manufacturing Plant/PVC Pipe Extrusion

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords