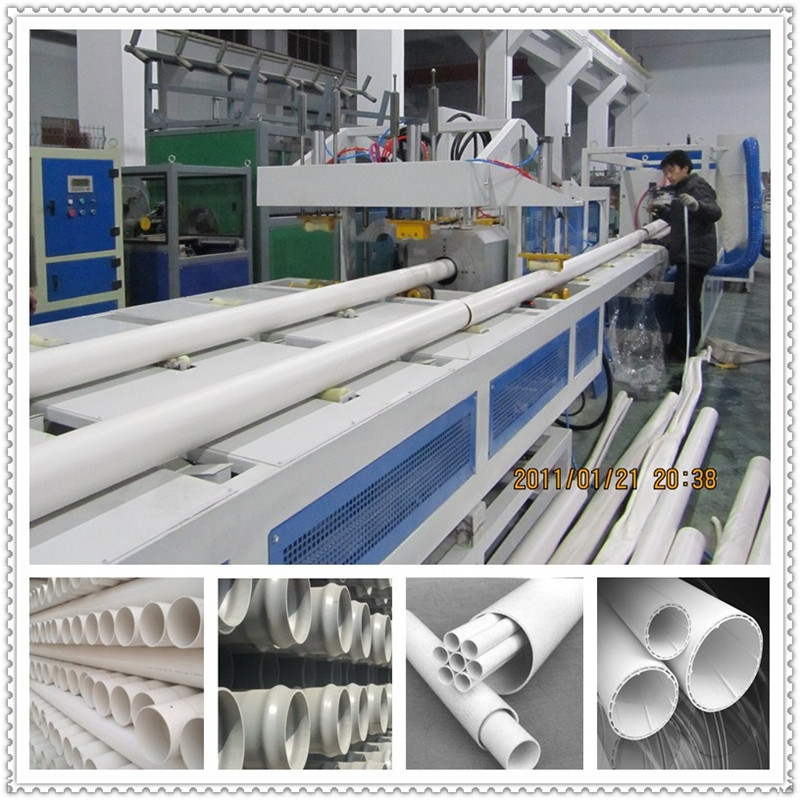

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New high output PVC small pipe machine wire conduit pipe making machine Double pipe production line PVC two pipe extrusion line PVC wire pipe extruder machine

The production line is development with the advanced technology of West Europe by our company. The main machine is SJSZ-51 or SJSZ-65 conical twin screw extruder is equipped with double-tube separate-control stainless steel spraying calibration.It avoids waste condition when one tube is adjusted and the other one is affected.

Small PVC wire pipe machine Production Line details:

1.AC motor,ABB frequency speed governor, Japanese RKC temperature controller, Schneider contactor.

2.Screw Nitriding treatment,hardness HV740-940,surface roughness Ra≤ 0.8um.

3.Barrel air-cooled cooling method, nitriding depth of 0.5- 0.7mm, hardness of HV860 or more, the surface roughness Ra ≤ 1.6um.

4.Die head material,High quality steel by quenching and tempering.Structure,Where contact with the materials hard chrome plating.Bolts level,12.9 high strength bolts.

5.Two Vacuum calibration tank material:Stainless steel.

6.Double Caterpillar adjusting method: pneumatic compress device.

7.Double cutter: Most cutting times,20 times/min;With strong waste clean device. Equipped with a meter installation, meter size is accurate.

8.Double stacker: Pneumatic flip, soft rubber, to prevent pipe surface scratch.

9.All electrical parts adopt world famous brand product.

Extruder For PVC small diameter conduit Pipe machine :

| Item | SJSZ-51 | SJSZ-65 |

| Diameter of screw(mm) | 51/105 | 65/132 |

| Screw rotation speed(rpm) | 1-45 | 1-35 |

| Power of Main engine(kw) | 18.5 | 37 |

| Production capacity(kg/h) | 80-150 | 250-300 |

| Net weight(kg) | 3200 | 4000 |

| Dimensions(mm)(L*W*H) | 3600*1100*2100 | 4235*1520*2450 |

We are the manufacturer specialized in plastic machine manufacture for many years,our products are exported to many countries.If you are interested in our products,please contact us at any time.

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- I've also encountered (missing a pulse alarm), and finally checked out is a SCR triggered, impassability, you can try

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q: Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Cable extruder type 657090 machine, describes the diameter of the screw, the unit is mm.The greater the number, the greater the equipment, the greater the amount of gumIt is usually marked on the control cabinet of the equipment

- Q: What is the adjustment method of China's extrusion machine die?

- (4) lamp alignment: suitable for polythene plastic wires and cables. Use light to illuminate the insulating layer and sheath, observe the upper, lower, left and right sides of the thickness, adjust the screw to the die until it is even, then screw the screws.

- Q: Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.Is the fitting of the moving parts normal?.Is there an impact on the extrusion chamber?.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q: Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q: What is the principle of the 45 extruder machine?

- The principle of the extruder is the theoretical process of heating, melting and mixing in the process of plastic conveying, including solid conveying principle, melt transportation principle, mixing principle, and solid bed crushing process, etc..

Send your message to us

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords