Carbon Steel Round Bar with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Steel Round Bar with High Quality

Specification

1, Diameter: 8mm-250mm rounds

5mm-9mm rods

2, Length: 2m, 3m, 5.8m, 6m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black, Polished, Galvanized

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

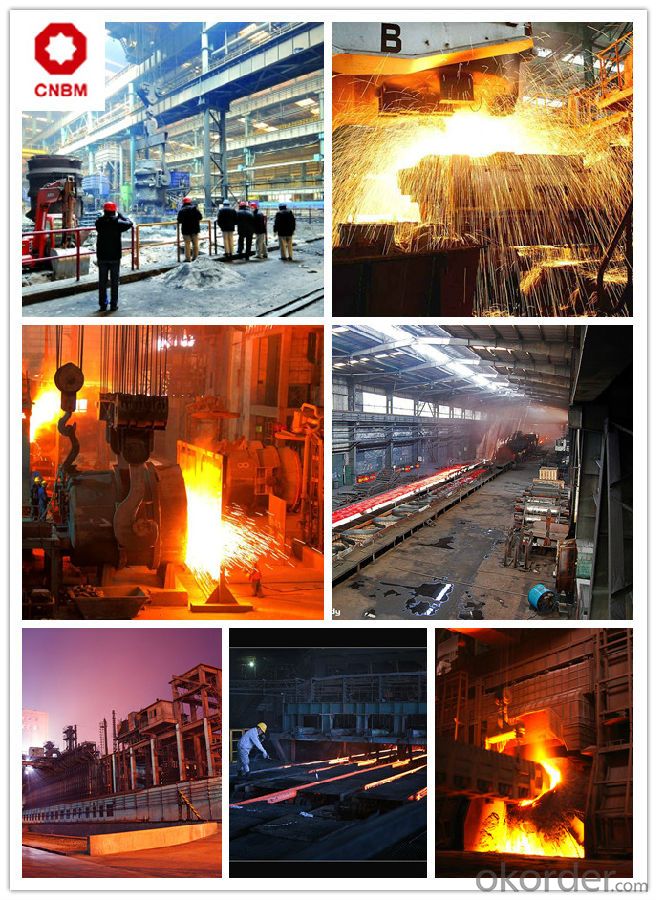

Products Show

Product Overviews

Description |

Carbon Steel Rod/Carbon Steel Bar,carbon steel rod,carbon steel shaft,mild steel bar, mild steel shaft,ms bar | |

Material |

ASTM |

1005,1006,1008,1010,1015,1020,1025,1030,1035,1040,1045,1050,1055,1060, 1065,1070,1080,1084,1016,1022 |

DIN |

Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 | |

BS |

040A04,095M15,045M10,080A40,045M10,080M50 | |

Standard | GB/T799,ASTM A29,A108,A321,A575,BS970,DIN1652,JIS G4051 | |

Section shape |

Round | |

Length |

As your required | |

Application | Carbon steel rod applies to chemical industry, shipping industry,manufacturing industry,construction, decorate Industry,electric power,pump shafts, sanitary wares,furniture handles,boiler,high temperature resistant,low temperature resistant, corrosion resistant. | |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: Can steel round bars be used in the energy industry?

- Yes, steel round bars can be used in the energy industry. Steel round bars are commonly used in various applications within the energy industry, such as in the construction of pipelines, power plants, and oil and gas infrastructure. They provide high strength and durability, making them suitable for withstanding the demanding conditions and requirements of the energy sector.

- Q: Can steel round bars be used in the production of power tools?

- Certainly! Steel round bars have the capability to be utilized in the manufacturing process of power tools. Steel, being a resilient and robust material, is frequently employed in the production of a wide range of tools and machinery, particularly power tools. The implementation of steel round bars can contribute to the creation of power tool bodies, handles, and other vital components, thereby enhancing stability, strength, and longevity. Power tool manufacturers often opt for steel with high tensile strength and resistance to wear and tear. Furthermore, steel possesses the advantage of being easily machinable, allowing for precise shaping and customization of power tool components. In summary, the utilization of steel round bars is a suitable and advantageous choice for the production of power tools due to their strength, durability, and versatility.

- Q: How do steel round bars compare to copper round bars?

- Steel round bars and copper round bars have distinct properties that make them suitable for different applications. Firstly, steel round bars are known for their exceptional strength and durability. Steel is a versatile and widely-used material that can withstand high levels of stress, making it ideal for structural and industrial applications. It has a high tensile strength, which means it can resist pulling forces without breaking. Steel round bars are commonly used in construction projects, automotive components, and machinery manufacturing. On the other hand, copper round bars possess unique characteristics that differentiate them from steel. Copper is an excellent conductor of heat and electricity, making it indispensable in electrical wiring and plumbing systems. It is also highly resistant to corrosion, which is why copper pipes are widely used in plumbing applications. Additionally, copper has antimicrobial properties, which makes it a preferred material for medical equipment and food processing industries. When it comes to cost, steel round bars are generally more affordable than copper round bars. Steel is abundantly available and its production cost is lower compared to copper. This cost advantage makes steel a popular choice for many budget-conscious applications. In terms of appearance, steel round bars have a sleek and metallic finish, while copper round bars have a distinct reddish-brown appearance. This visual difference often influences the choice between the two materials in architectural and decorative applications. In summary, steel round bars and copper round bars have different properties that make them suited for specific purposes. Steel offers exceptional strength and durability, making it suitable for structural and industrial applications, while copper is valued for its conductivity, corrosion resistance, and antimicrobial properties, making it ideal for electrical, plumbing, and medical applications. The choice between steel and copper depends on the specific requirements of the project and the desired properties of the material.

- Q: Can steel round bars be used in the construction industry?

- Yes, steel round bars are commonly used in the construction industry for various applications. They are often used as reinforcement in concrete structures, such as beams, columns, and slabs, to enhance their strength and durability. Steel round bars can also be used in the fabrication of structural components, such as trusses, frames, and supports, due to their high tensile strength and resistance to bending or breaking. Additionally, they can be employed in the construction of bridges, tunnels, buildings, and other infrastructure projects.

- Q: What are the different types of steel round bar coatings used in the marine industry?

- There are several types of steel round bar coatings commonly used in the marine industry, including galvanized coatings, epoxy coatings, and corrosion-resistant coatings. These coatings help protect the steel from rust and corrosion caused by exposure to saltwater and other harsh marine environments.

- Q: What is the resistance to wear of a steel round bar?

- The resistance to wear of a steel round bar is generally high due to its hardness and durability.

- Q: Are steel round bars available in different lengths?

- Yes, steel round bars are available in different lengths. Steel round bars come in various lengths to accommodate different needs and applications. The length options can vary depending on the supplier or manufacturer. Common lengths for steel round bars range from 6 to 12 feet, but custom lengths can also be obtained through special requests. The availability of different lengths allows for greater flexibility in construction and fabrication projects, as it enables the bars to be cut or modified to specific requirements.

- Q: How are steel round bars used in the construction of bridges and buildings?

- Steel round bars are commonly used in the construction of bridges and buildings as they provide structural support and help distribute the load evenly. These bars are used to reinforce concrete structures, such as columns and beams, ensuring increased strength and stability. Additionally, steel round bars can be utilized as tension members in bridge construction, helping to withstand heavy loads and maintain structural integrity.

- Q: How are steel round bars used in the manufacturing of agricultural implements?

- Steel round bars are commonly used in the manufacturing of agricultural implements due to their strength and durability. These bars are used as a primary material for constructing various components of agricultural tools such as plows, cultivators, tillers, and harrows. The high tensile strength of steel round bars allows these implements to withstand the rigorous demands of agricultural operations, ensuring long-lasting performance and efficient use in the field.

- Q: What are the different heat treatment methods for steel round bars?

- Steel round bars can undergo various heat treatment methods to enhance their mechanical properties and overall performance. These methods, namely annealing, normalizing, quenching, tempering, and case hardening, are commonly employed. 1. Annealing: By subjecting the steel round bars to a specific temperature and maintaining it for a certain duration, annealing achieves a uniform microstructure. This treatment alleviates internal stresses, improves ductility, and enhances machinability. 2. Normalizing: This technique involves heating the steel round bars slightly above their critical transformation temperature and subsequently cooling them in still air. Normalizing refines the grain structure, enhances mechanical properties, and improves resistance to impact and fatigue. 3. Quenching: The process of quenching entails heating the steel round bars above their critical temperature and rapidly cooling them by immersion in a quenching medium like oil, water, or brine. This rapid cooling hardens the steel, rendering it stronger and more resistant to wear and abrasion. However, quenched steel may exhibit brittleness, necessitating additional heat treatment steps. 4. Tempering: Following the quenching process, tempering is often employed to reduce brittleness and enhance toughness. Tempering involves reheating the quenched steel to a specific temperature and holding it there for a designated time, followed by gradual cooling. This procedure alleviates internal stresses, improves ductility, and enhances overall toughness and machinability. 5. Case Hardening: Case hardening is a surface heat treatment method that increases the hardness of the outer layer of steel round bars while maintaining a relatively softer core. This technique involves heating the steel in a carbon-rich environment, such as a gas or salt bath, and subsequently quenching it to achieve a hardened outer layer. Case hardening improves wear resistance and fatigue strength, making it suitable for applications requiring high surface hardness. It is crucial to note that the selection of the specific heat treatment method for steel round bars depends on the desired mechanical properties and intended application. Manufacturers meticulously choose the appropriate heat treatment method based on factors such as steel composition, desired hardness, and required strength.

Send your message to us

Carbon Steel Round Bar with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords