Grade 316 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade 316 Stainless Steel Round Bar in stock

Descriptio of Grade 316 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade 316 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade 316 Steel Round Bar in Stock

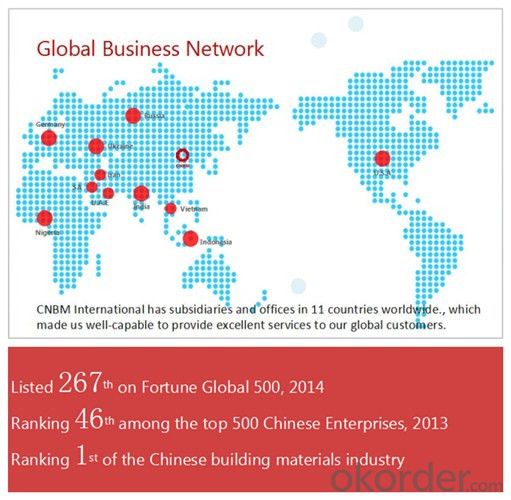

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade 316 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How does special steel perform in power generation applications?

- Special steel is highly regarded in power generation applications due to its exceptional strength, resistance to corrosion, and ability to withstand high temperatures. These qualities make it ideal for the construction of critical components such as turbine blades, steam generators, and boiler tubes. Special steel's superior performance ensures efficient and reliable power generation, contributing to increased productivity and longevity of power plants.

- Q: What are the different cutting tools used for machining special steel?

- Some different cutting tools used for machining special steel include carbide inserts, high-speed steel (HSS) end mills, diamond-coated tools, and ceramic cutting tools. These tools are designed to withstand the high hardness and heat resistance of special steels, ensuring precise and efficient cutting operations.

- Q: How does special steel enhance the performance of cutting tools?

- Special steel enhances the performance of cutting tools by providing increased durability, hardness, and resistance to wear and deformation. This allows cutting tools to maintain their sharpness and precision for longer periods, resulting in improved cutting efficiency and effectiveness.

- Q: What are the properties of wear-resistant steel?

- Wear-resistant steel possesses several properties that make it suitable for withstanding wear and abrasion. These properties include high hardness, toughness, and strength, which help in resisting deformation, chipping, and cracking. Additionally, wear-resistant steel also exhibits excellent corrosion resistance, enabling it to withstand exposure to harsh environments without deteriorating. These properties make wear-resistant steel a popular choice for applications that involve heavy machinery, mining equipment, cutting tools, and industrial components subjected to constant wear and tear.

- Q: How does special steel contribute to the automotive fuel efficiency?

- Special steel contributes to automotive fuel efficiency in several ways. Firstly, special steel is often used in the construction of lighter and stronger components such as the chassis, body panels, and engine parts. This reduces the overall weight of the vehicle, leading to improved fuel economy. Secondly, special steel can be used in the manufacturing of components like exhaust systems, which are designed to reduce emissions and improve fuel efficiency. Additionally, special steel can also be utilized in the production of more efficient engine designs, such as turbochargers, which enhance the power output while minimizing fuel consumption. Overall, the use of special steel in the automotive industry plays a crucial role in enhancing fuel efficiency and reducing environmental impact.

- Q: How does special steel perform in high-pressure hydrogen environments?

- Special steel performs well in high-pressure hydrogen environments due to its high strength, corrosion resistance, and ability to withstand hydrogen embrittlement. It is specifically designed to resist the damaging effects of hydrogen, making it a reliable choice for applications in these environments.

- Q: What are the requirements for special steel used in high-pressure applications?

- Special steel used in high-pressure applications must meet certain requirements in order to ensure its durability and reliability under extreme conditions. Some of the key requirements for this type of steel include: 1. High strength: Special steel for high-pressure applications needs to have exceptional strength to withstand the intense forces and pressures it will be subjected to. This allows it to resist deformation and maintain its structural integrity. 2. Excellent corrosion resistance: The steel must have a high resistance to corrosion, as it will often come into contact with aggressive fluids or gases in high-pressure environments. This prevents the steel from deteriorating over time and helps to maintain its performance and longevity. 3. Good weldability: Special steel used in high-pressure applications should possess good weldability to enable easy and efficient joining of different components. This ensures the overall integrity and reliability of the system. 4. High temperature resistance: The steel must have the ability to withstand elevated temperatures without losing its mechanical properties. This is particularly important in applications where high-pressure fluids or gases are heated or where the steel is exposed to extreme heat sources. 5. Fatigue resistance: Special steel should have a high resistance to fatigue failure, as it will often be subjected to cyclic loading and pressure fluctuations. This allows the steel to withstand repeated stress and pressure cycles without developing cracks or failures. 6. Tight dimensional tolerance: The steel should have tight dimensional tolerance to ensure proper fit and functionality within the high-pressure system. This helps to minimize leakage or any potential weak points in the system. 7. Compliance with industry standards: Special steel used in high-pressure applications should meet relevant industry standards and specifications, such as those set by organizations like the American Society of Mechanical Engineers (ASME) or the American Petroleum Institute (API). This ensures that the steel meets the required quality and performance standards. Overall, special steel for high-pressure applications needs to possess a combination of high strength, excellent corrosion resistance, good weldability, high temperature resistance, fatigue resistance, tight dimensional tolerance, and compliance with industry standards to ensure its suitability and reliability in demanding environments.

- Q: What are the different methods of improving the wear resistance of special steel?

- There are several methods of improving the wear resistance of special steel. One common method is through heat treatment, which involves heating and cooling the steel to modify its microstructure and improve hardness. Another method is through alloying, where different elements are added to the steel to enhance its wear resistance properties. Additionally, surface treatments like nitriding, carburizing, and coating can also be employed to improve wear resistance. Overall, a combination of these methods can significantly enhance the wear resistance of special steel.

- Q: How does special steel perform in high-frequency applications?

- High-frequency applications benefit greatly from special steel, also known as high-speed steel (HSS), due to its remarkable performance. This steel is specifically engineered to endure the intense heat and stress encountered during high-speed machining operations. The distinctive composition of special steel, which typically includes elements like tungsten, molybdenum, cobalt, and vanadium, grants it exceptional hardness, toughness, and resistance to wear. These properties make it highly suitable for high-frequency applications that involve rapid cutting speeds and frequent abrasion. Special steel's excellent hardness allows it to maintain its cutting edge even at elevated temperatures, ensuring superior performance in high-frequency applications. It experiences minimal deformation or loss of cutting efficiency, resulting in increased productivity and tool longevity. Additionally, its exceptional wear resistance enables it to withstand the constant friction and heat generated during high-speed machining operations, thus preventing premature tool failure. Furthermore, special steel possesses excellent thermal conductivity, which aids in dissipating the heat produced during high-frequency applications. This characteristic is crucial for preserving dimensional stability and preventing warping or distortion under extreme temperatures. Consequently, special steel tools can maintain their precision and accuracy even during prolonged high-frequency operations. In conclusion, special steel's exceptional hardness, toughness, wear resistance, and thermal conductivity make it highly effective in high-frequency applications. Its ability to withstand extreme heat and stress while preserving cutting performance and dimensional stability has established it as the preferred choice in industries such as aerospace, automotive, and manufacturing, where high-speed machining is indispensable.

- Q: Can special steel be used in the solar panel manufacturing industry?

- Yes, special steel can be used in the solar panel manufacturing industry. Special steel alloys, such as stainless steel or high-strength low-alloy steel, offer excellent corrosion resistance, durability, and structural support for solar panels. These properties make them suitable for various components like mounting structures, frames, and support brackets in solar panel systems. Additionally, special steel can also enhance the overall efficiency and longevity of solar panels by ensuring their stability and resistance to environmental factors.

Send your message to us

Grade 316 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords