All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

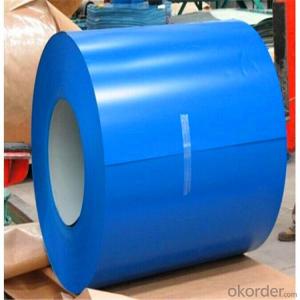

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does special steel ensure product safety in the food processing sector?

Special steel ensures product safety in the food processing sector by offering numerous benefits such as high corrosion resistance, easy cleaning and sanitization, and resistance to high temperatures. These properties prevent the accumulation of harmful bacteria and contaminants on the steel surfaces, ensuring a hygienic environment for food processing. Additionally, special steel's strength and durability provide long-lasting equipment that is less prone to breakage or contamination, further enhancing the safety of food products.

How does steel contribute to the development of sustainable transportation infrastructure?

Steel contributes to the development of sustainable transportation infrastructure in several ways. Firstly, steel is a highly durable material that can withstand heavy loads and harsh weather conditions, ensuring the longevity and reliability of transportation structures such as bridges, highways, and railways. This reduces the need for frequent repairs and replacements, resulting in lower maintenance costs and less waste generation.

Additionally, steel is a recyclable material, meaning it can be reused in the production of new infrastructure components. By incorporating recycled steel into transportation projects, the demand for virgin steel is reduced, leading to energy and resource savings, as well as a decrease in greenhouse gas emissions associated with steel production.

Furthermore, steel's strength-to-weight ratio enables the construction of lighter and more efficient transportation structures. This allows for the design of longer spans and taller structures, reducing the overall material requirements and minimizing the environmental impact associated with construction.

Overall, steel's durability, recyclability, and efficiency make it an essential component in the development of sustainable transportation infrastructure, promoting long-term economic and environmental benefits.

How does the production of special steel differ from conventional steel?

The production of special steel differs from conventional steel in terms of the composition and manufacturing process. Special steel is made by adding specific alloying elements to enhance its properties such as strength, hardness, corrosion resistance, or heat resistance. This requires precise control over the alloying elements and their proportions during the steelmaking process. In contrast, conventional steel is made using primarily iron and carbon, with minimal addition of other elements. Additionally, the manufacturing process for special steel may involve additional steps such as heat treatment, forging, or rolling to achieve the desired properties, whereas conventional steel is typically produced through basic steelmaking processes such as melting, refining, and casting. Overall, the production of special steel involves more precise control and tailored processes to meet specific performance requirements.

Wholesale Special Steel from supplier in Mali

We are a Special Steel supplier serving the Mali, mainly engaged in the sale, quotation, and technical support services of various Special Steel products in the Mali region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Special Steel procurement services in the Mali. Not only do we have a wide range of Special Steel products, but after years of market development in the Mali, we can also provide valuable experience for your projects.